Longitudinal-rib-above-arranged steel-concrete-steel-shell-combining-beam cable-stayed bridge

A top-mounted, cable-stayed bridge technology, applied to cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of complex design and construction of the steel-concrete transition section of mixed-girder cable-stayed bridges, a large number of welds, and slow construction speed , to achieve the effect of being conducive to track stability, improving durability and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

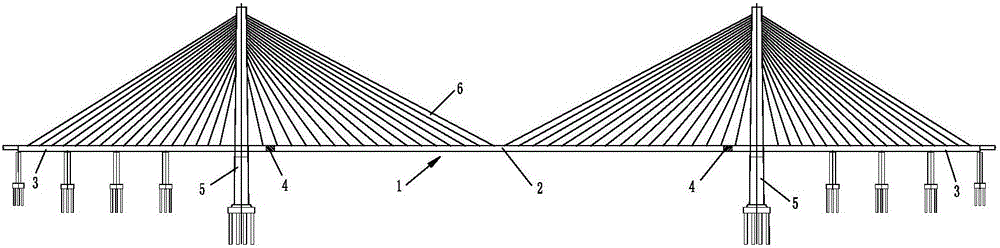

[0032] As shown in Fig. 1, a cable-stayed bridge with longitudinal ribs above the steel-concrete steel shell combined girders includes the main girder 1 of the cable-stayed bridge. The side span 3 and the transition section 4 arranged between the main span 2 and the side span 3 are composed. The two sides of the main girder 1 of the cable-stayed bridge in the length direction are provided with main towers 5 vertically arranged at intervals, and each main tower 5 The top of the cable-stayed bridge and the main girder 1 of the cable-stayed bridge are fixedly connected by several stay cables 6, the main span 2 is a steel-concrete composite integral steel box girder structure, and the side span 3 is a steel-concrete composite steel shell concrete beam structure.

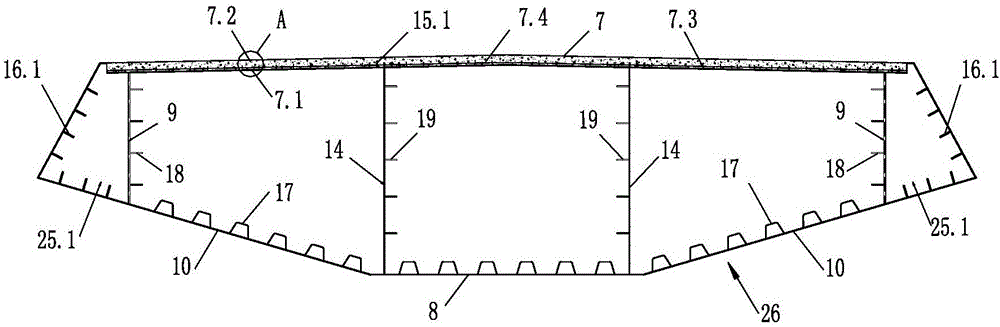

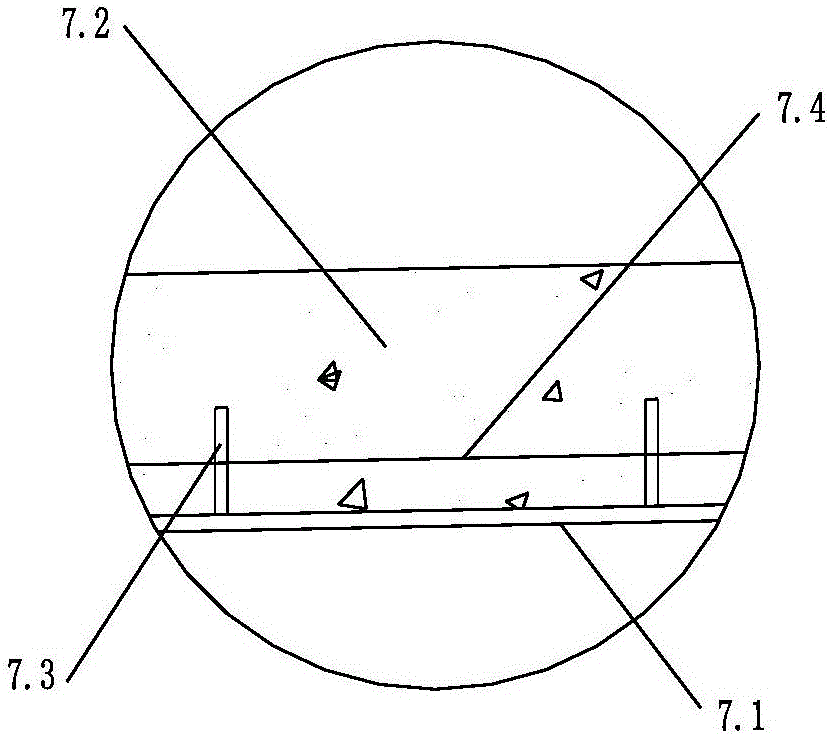

[0033] Such as figure 2 and image 3As shown, the steel-concrete composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com