Multi-motor hydraulic synchronous control system

A control system, hydraulic synchronization technology, applied in the direction of servo motors, fluid pressure actuators, mechanical equipment, etc., can solve problems such as nut failure, nut stuck, nut magazine can not move forward, etc., to achieve synchronization problems, high synchronization The effect of precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

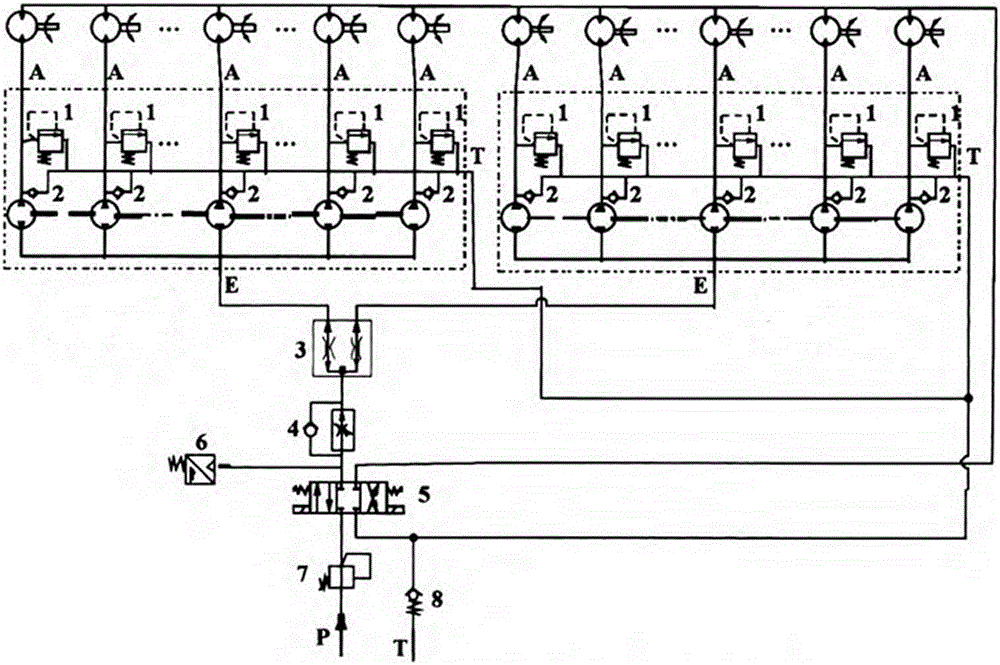

[0014] like figure 1 , The control system adopts an open-loop control system. The open-loop hydraulic synchronous control system has a throttle valve synchronous circuit, a speed control valve synchronous circuit, a diverter valve synchronous circuit, a synchronous diverter (synchronous diverter motor) synchronous circuit, and a parallel pump synchronous circuit.

[0015] The control system uses diverter valves for synchronous design, which requires 51 diverter valves, which is expensive, and the synchronization accuracy will decrease sharply after multi-stage diversion. This method considers the motor as an ideal state, and only controls the flow of hydraulic oil flowing into the motor, without considering the leakage of the motor and the influence of mechanical friction on the rotational speed. The synchronous circuit system controlled by the speed regulating valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com