A Manufacturing Technology of Dense Saber Coaming Hinge

A manufacturing technology, tooth plate technology, applied in the manufacturing field of dense saber-tooth coaming hinges, can solve the problems of poor load-bearing capacity, small stability, unable to meet the needs of packaging, etc., to achieve high strength, thick box plate, and firm connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

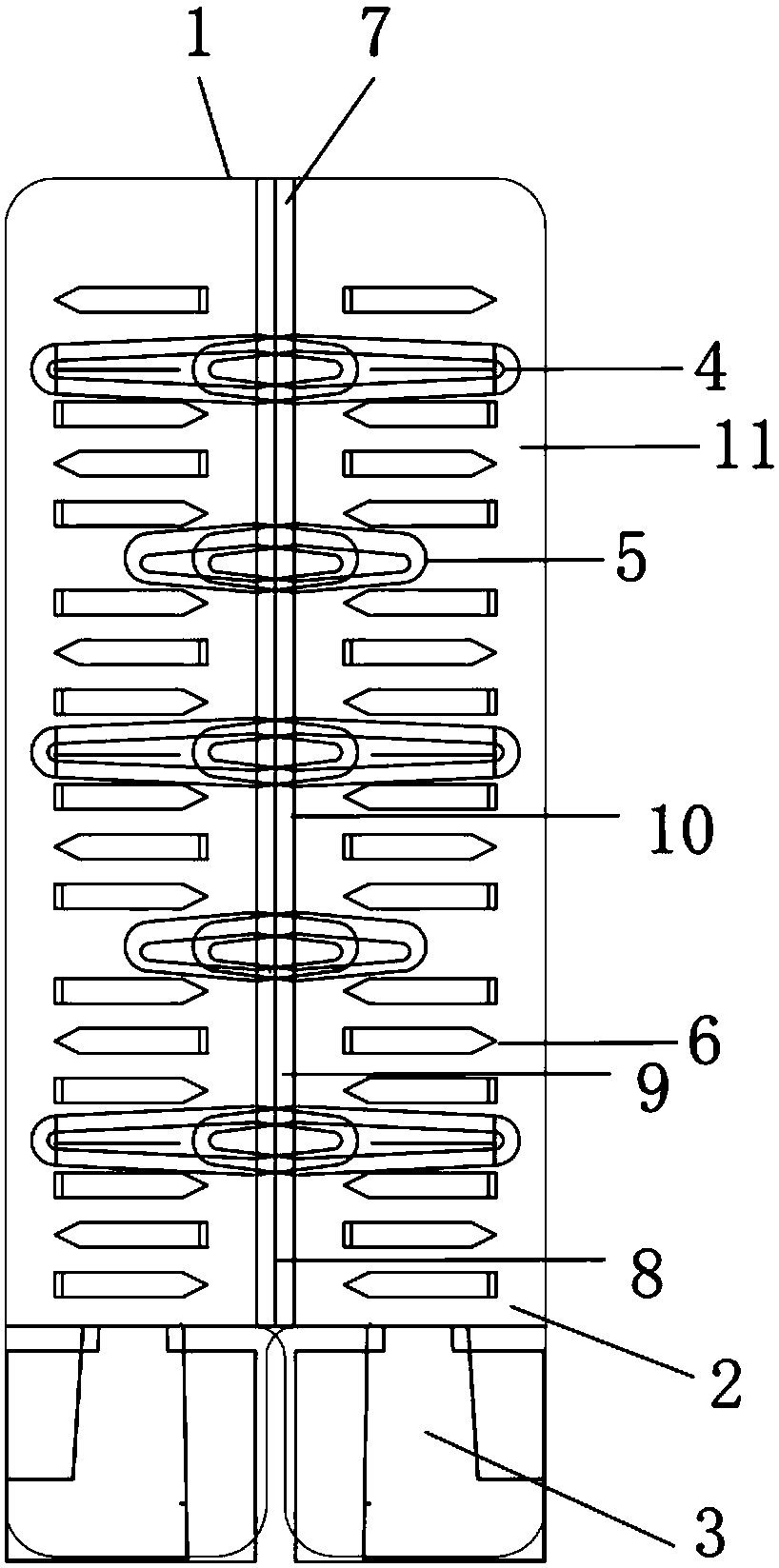

[0023] Such as figure 1 As shown, a manufacturing technology of dense saber-tooth coaming hinge, including hinge plate 1, saber-tooth plate 2, saber-tooth plate foot 3, hinge plate long transverse ridge 4, hinge plate short transverse ridge 5, sword Teeth 6, link plate 7, link bushing 8, bushing notch 9, hinge shaft 10, saber-tooth plate 11.

[0024] First, the saber-tooth plate 2 and the link plate 7 are set on the hinge plate 1, and then the saber-tooth plate foot 3, the long transverse ridge of the hinge plate 4, and the short hinge plate are set on the saber-tooth plate 2. Transverse ridges 5, saber teeth 6 and saber tooth plates 11.

[0025] Then, the link bushing 8 and the bushing notch 9 are arranged on the link plate 7 . Finally, the hinge plates 1 that match the two link bushings 8 and the bush gaps 9 are matched together, and the hinge shaft 10 is set in the link bushing 8 to complete a dense saber-tooth coaming Hinge implementation.

Embodiment 2

[0027] Such as figure 1 As shown, a kind of dense saber-tooth coaming hinge manufacturing technology also includes the following steps:

[0028] Step 1, material preparation: stamping and cutting the steel plate into steel sheets with the shape and size of the hinge plate,

[0029] Step 2, stamping the hinge slab: (1) Stamping the long transverse ridges of the hinge plate and the short transverse ridges of the hinge plate on the steel sheet at equidistant intervals from the inside to the outside, (2) further pressing the steel plate Stamping into two vertical faces, a narrow face and a wide face, and then cut off a section at one end of the narrow face to make a hinge slab,

[0030] Step 3. Stamping the saber-toothed plate: (1) stamping the protruding end of the wide surface of the hinge slab to form a streamlined outwardly curved saber-toothed plate foot and a said saber-toothed plate. The saber-tooth plate foot and the saber-tooth plate are parallel planes, (2) stamping th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com