Using method of fastening base of equipment monitor

A monitor and fastening technology, which is applied in the field of monitoring and fixing devices, can solve the problems of camera loosening, time-consuming and labor-intensive, corrosion, etc., and achieve the effects of quick disassembly and installation, improved service life, and increased detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

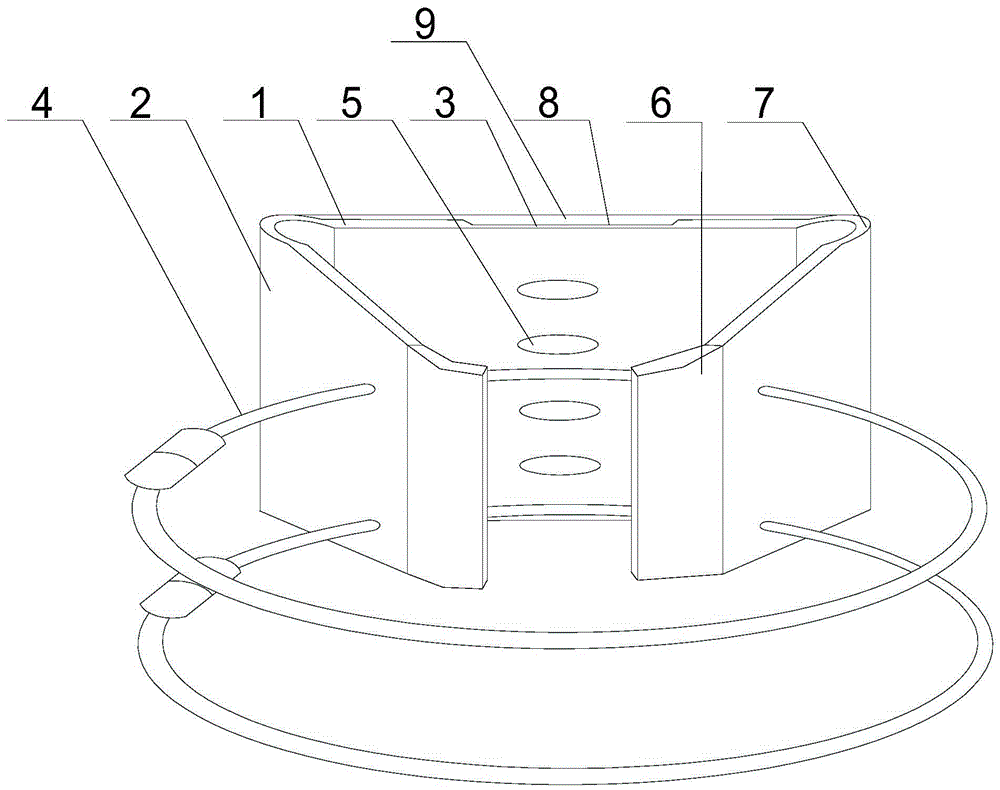

[0026] like figure 1 Shown, the present invention comprises the following steps:

[0027] A First place the ends of the two fixed plates on the rod-shaped support structure;

[0028] B then fasten the dovetail mounting seat formed by the two fixing plates and the bottom plate on the outer peripheral wall of the drying support structure through the clamp;

[0029] C. An elastic arc-shaped plate is added to the connecting part between the fixed plate and the bottom plate. When the clamp shrinks, the sudden stress on the arc-shaped plate can be directly eliminated by the arc-shaped metal plate with certain deformation capacity;

[0030] D The adjustment plate can be in contact with the outer circumferential wall of the support structure before the fixed plate contacts the outer circumferential wall of the support structure, so as to realize the flexible connection between the mounting seat and the support structure. When the monitoring equipment is shaken by external force, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com