Intermediate structure of micro-LED unit and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of difficult mass production, high production cost, labor and time consumption, etc., and achieve success rate and efficiency improvement , the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

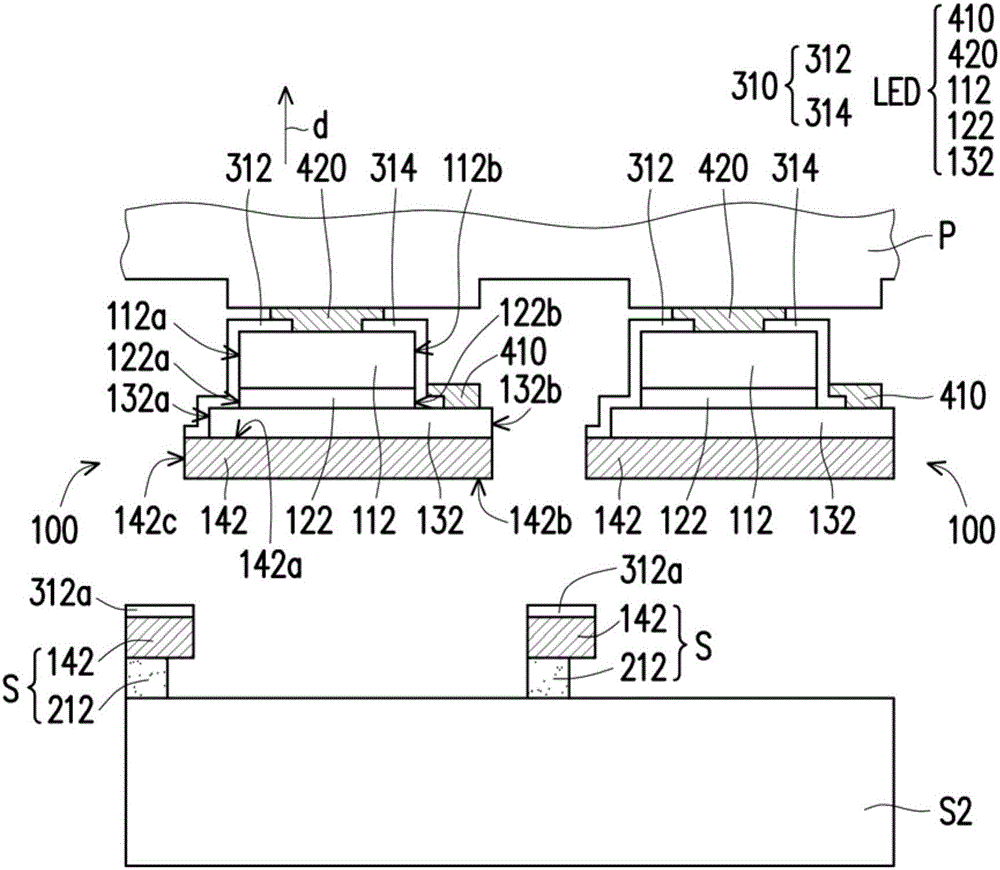

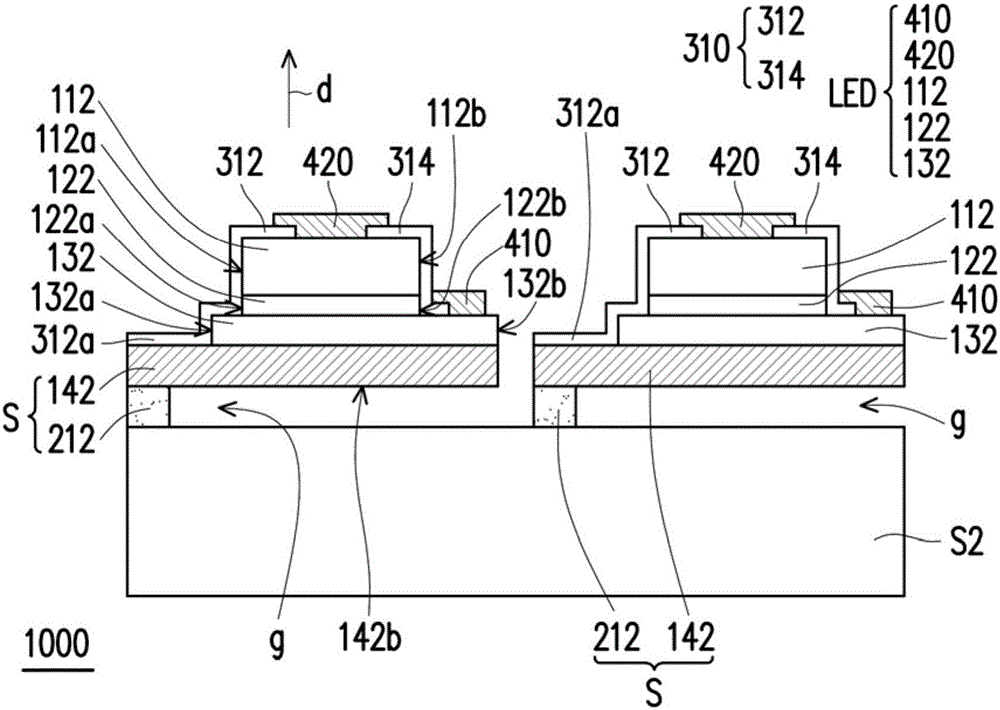

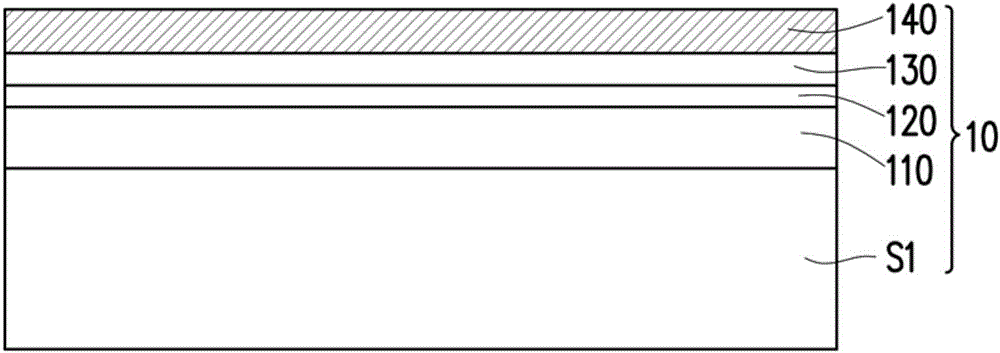

[0095] Figure 1A to Figure 1J It is a schematic cross-sectional view of a manufacturing method of a micro LED device according to an embodiment of the present invention. Figure 1A to Figure 1H It is a schematic cross-sectional view of the manufacturing method of the micro-LED intermediary structure. Please refer to Figure 1A , firstly, a semiconductor structure 10 is provided. The semiconductor structure 10 includes multiple semiconductor layers (not labeled) and a first sacrificial layer 140 stacked on the inner surface of the growth substrate S1 in sequence. The first sacrificial layer 140 is disposed on the multi-layer semiconductor. The multilayer semiconductor includes a first-type semiconductor layer 130 and a second-type semiconductor layer 110 opposite in polarity to the first-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com