Automatic bread maker

A bread machine and automatic technology, which is applied to dough mixers, structural parts of mixing/kneading machines, baking, etc., can solve problems such as the inability to achieve accurate proportioning of raw materials, reduce the degree of automation of bread machines, and single functions of bread machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings:

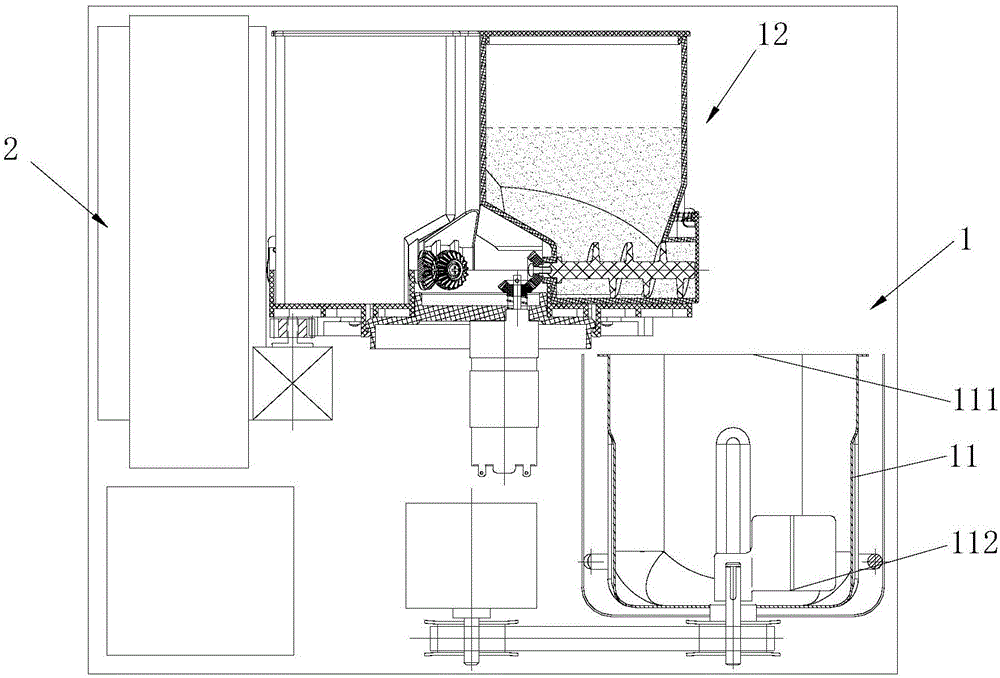

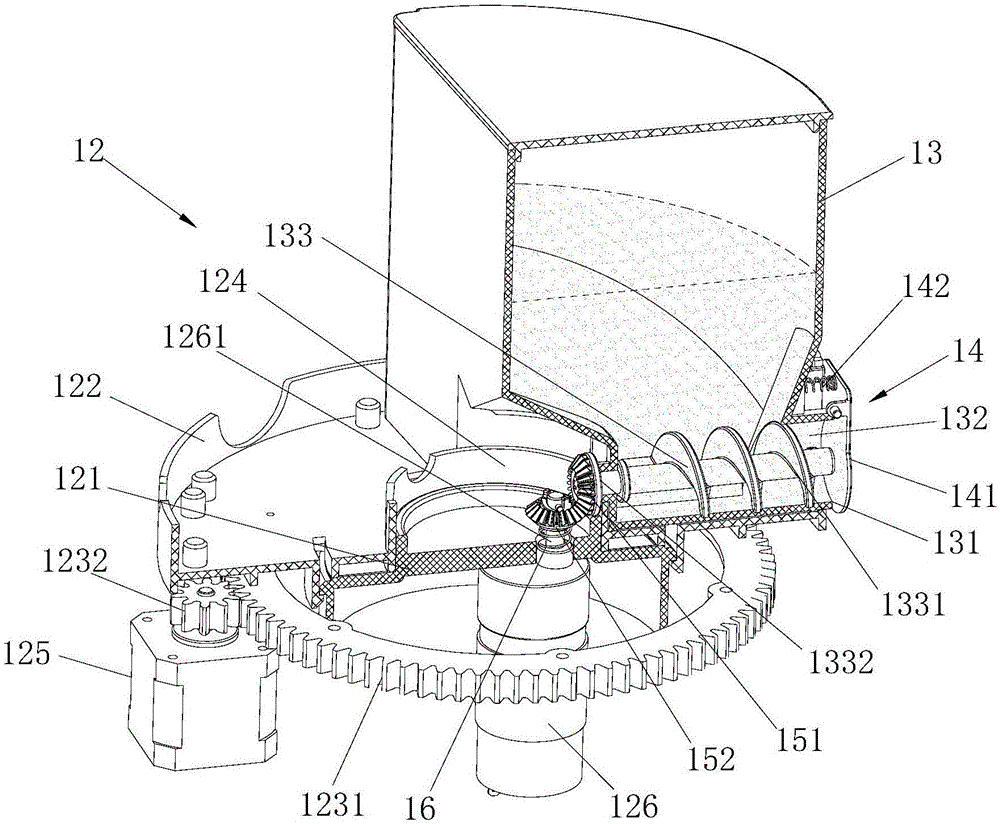

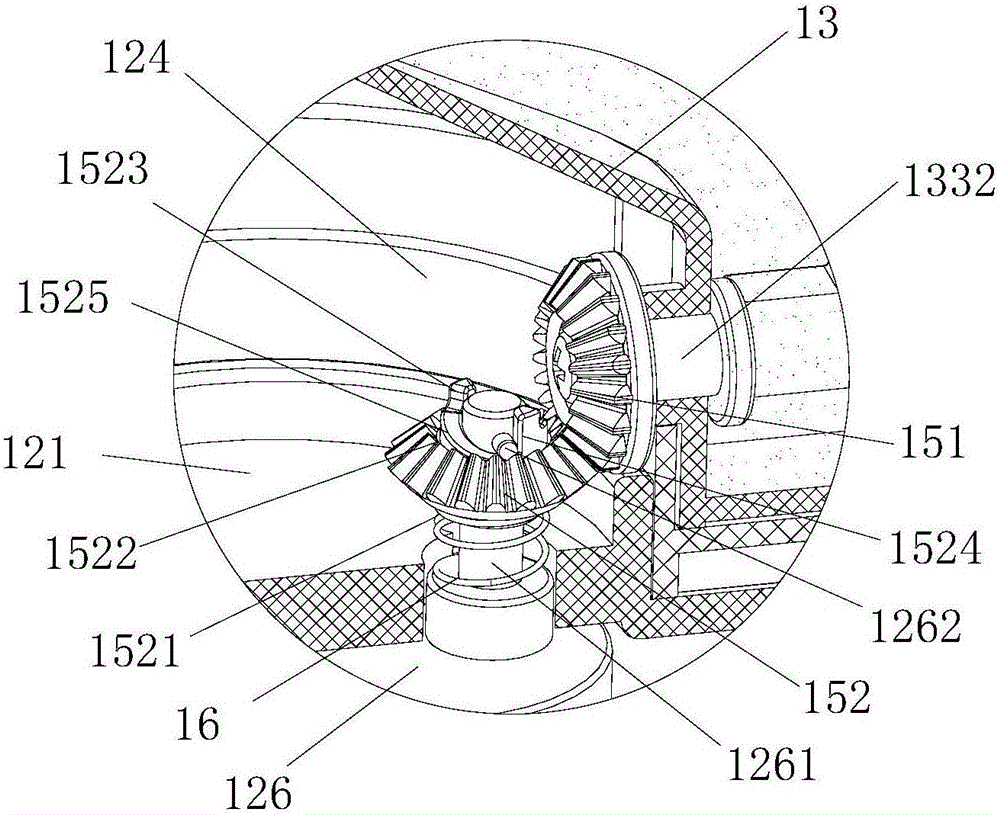

[0035] like figure 1 ,2 As shown in , 3 and 4, this embodiment includes a rack, a noodle mixing device 1, a fresh egg adding device 2 and a single-chip microcomputer (using STMicroelectronics STM32F769 model) installed on the rack (not shown in the figure). The dough mixing device 1 includes a stirring chamber 11 with a feeding port 111 and a feeding control mechanism 12. A stirring mechanism 112 is installed in the stirring chamber 11. The turntable 122 (circular structure) above the material opening 111, the base 121 is provided with a protruding circular positioning table, the turntable 122 is provided with a circular groove matching the circular positioning table, and the turntable 122 passes through the circular positioning table. The groove is rotatably matched with the base 121 . A bin selection driven gear 1231 is coaxially fixed at the turntable 122, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com