High-dropping point corrosion-resistant seal wax for cable and anchor head of bridge and preparation method of the seal wax

A high drop point, sealing wax technology, applied in wax coatings, coatings, anti-corrosion coatings, etc., can solve the problems of long light time, plasticizer migration, limited use area, etc., to achieve low viscosity, compatibility Good and beneficial to the effect of engineering perfusion construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

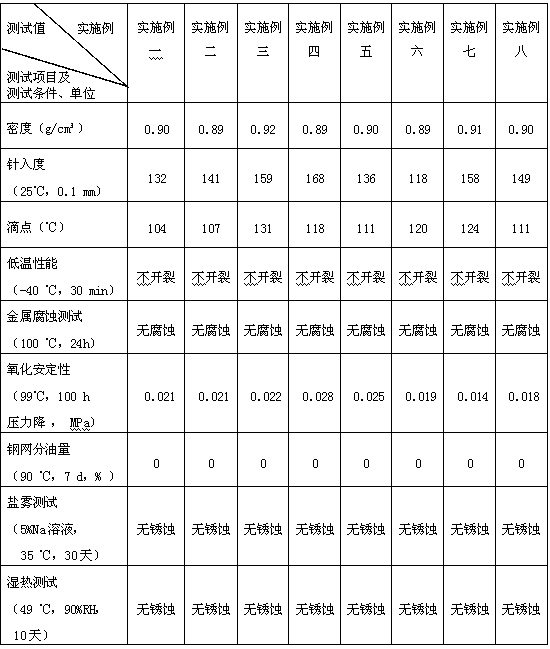

Examples

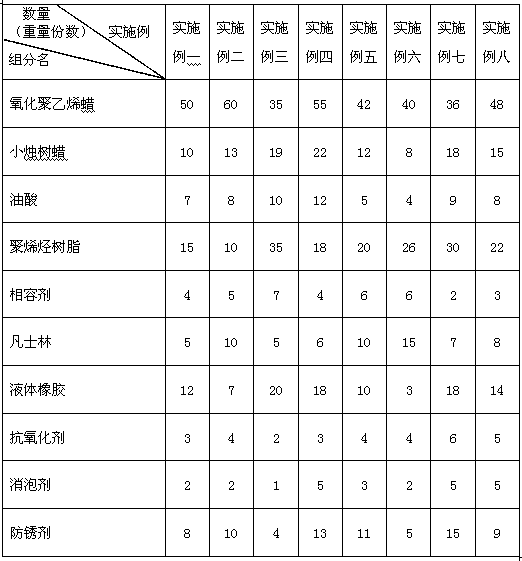

Embodiment 1

[0047] A kind of high dropping point anti-corrosion sealing wax for bridge cables and anchor heads and its production method Ⅰ:

[0048] The high drop point corrosion-resistant sealing wax for bridge cables and anchor heads is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated as follows in parts by weight:

[0049] 50 parts by weight of oxidized polyethylene wax,

[0050] Candelilla wax 10 parts by weight,

[0051] 7 parts by weight of oleic acid,

[0052] Polyolefin resin——15 parts by weight, including 10 parts by weight of polyethylene and 5 parts by weight of polyvinyl chloride;

[0053] Compatilizer——4 parts by weight of ethylene bisoleic acid amide,

[0054] Vaseline 5 parts by weight,

[0055] Liquid rubber——12 parts by weight, including 5 parts by weight of nitrile rubber, and 7 parts by weight of butyl rubber;

[0056] Antioxidant——2,6 di-tert-butyl-p-cresol 3 parts by weight,

[0057] Defoamer...

Embodiment 2

[0063] A kind of high dropping point anti-corrosion sealing wax for bridge cables and anchor heads and its production method II:

[0064] The high drop point corrosion-resistant sealing wax for bridge cables and anchor heads is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated as follows in parts by weight:

[0065] 60 parts by weight of oxidized polyethylene wax,

[0066] Candelilla wax 13 parts by weight,

[0067] 8 parts by weight of oleic acid,

[0068] Polyolefin resin—10 parts by weight of polypropylene;

[0069] Compatilizer-5 parts by weight, including 2 parts by weight of ethylene bis stearamide, 3 parts by weight of ethyl 3-ethoxy propionate;

[0070] 10 parts by weight of petroleum jelly;

[0071] Liquid rubber—7 parts by weight of EPDM;

[0072] Antioxidant -- 4 parts by weight, including 2 parts by weight of N-phenyl-a-naphthylamine, 2 parts by weight of zinc dialkyldithiophosphate;

[007...

Embodiment 3

[0079] A high drop point corrosion-resistant sealing wax for bridge cables and anchor heads and its production method III:

[0080] The high drop point corrosion-resistant sealing wax for bridge cables and anchor heads is a mixture composed of the following components. In the mixture, the proportion of each component material is calculated as follows in parts by weight:

[0081] 35 parts by weight of oxidized polyethylene wax,

[0082] Candelilla wax 19 parts by weight,

[0083] 10 parts by weight of oleic acid,

[0084] Polyolefin resin——35 parts by weight of amorphous polyalpha-olefin,

[0085] Compatilizer-7 parts by weight, including 3 parts by weight of polyvinyl alcohol, 4 parts by weight of sorbitan monooleate;

[0086] Vaseline 5 parts by weight,

[0087] Liquid rubber——20 parts by weight of styrene-butadiene rubber,

[0088] Antioxidant——Tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester 2 parts by weight,

[0089] Defoamer---1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com