A connection node between an h-shaped steel beam and a rectangular steel tube concrete column and its manufacturing method

A technology of rectangular steel tube and concrete column, applied in the direction of building, building structure, etc., can solve the problems affecting the overall mechanical performance of the rectangular steel tube concrete column, the influence of the compact core concrete, the difficulty of pouring the core concrete, etc., so as to optimize the welding construction. method, the effect of reducing construction complexity and reliable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In conjunction with the accompanying drawings of the embodiments, the present invention is described in detail:

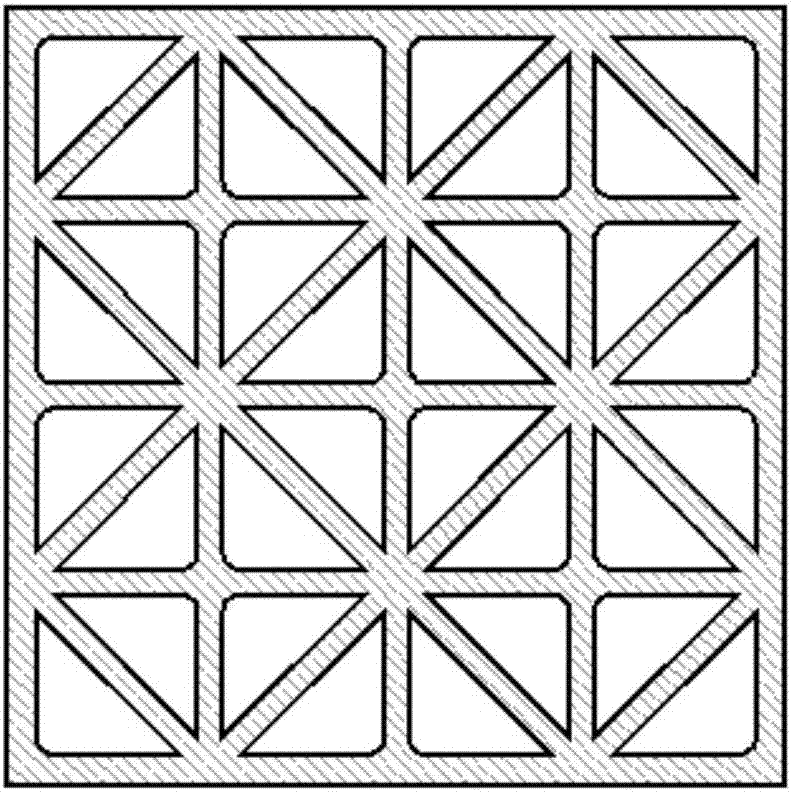

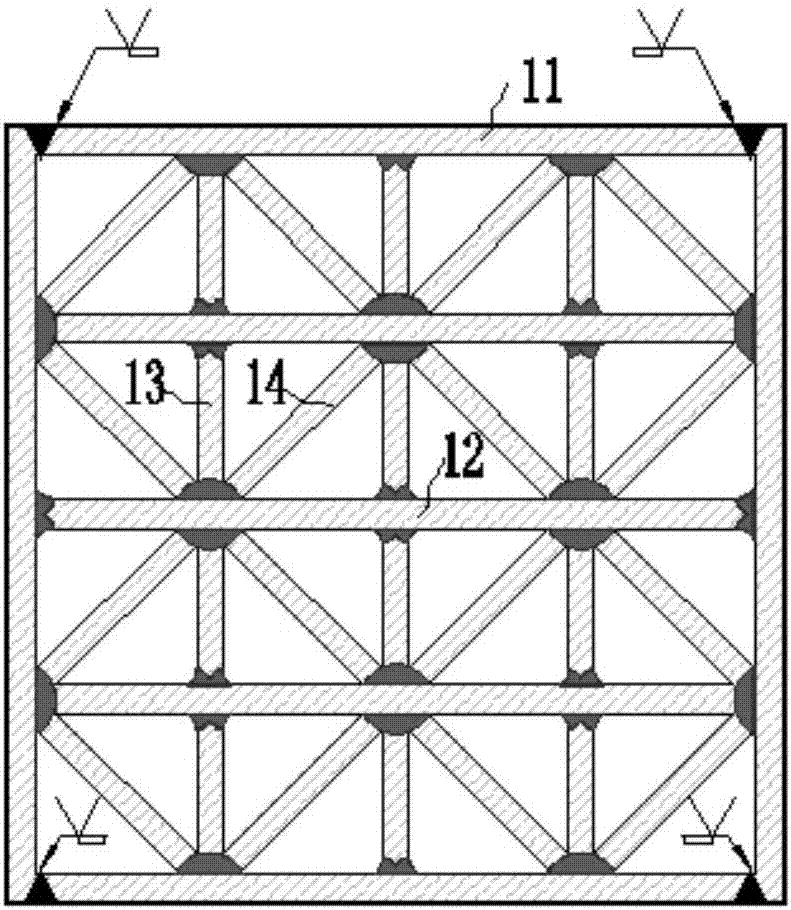

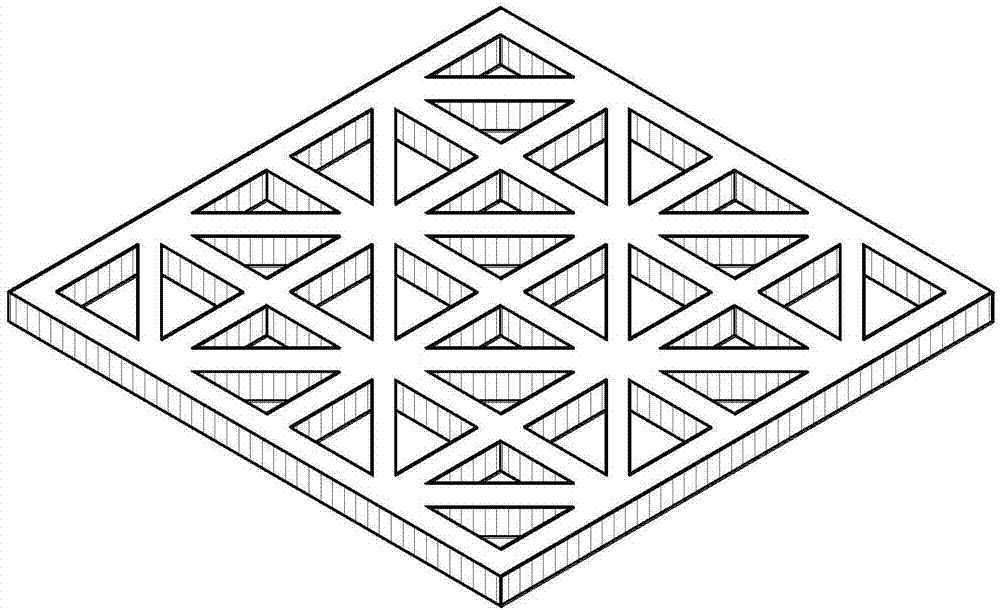

[0048] like Figure 1 to Figure 7 As shown, a connection node between an H-shaped steel beam and a rectangular steel tube concrete column is composed of a rectangular steel tube concrete column, an H-shaped steel beam and connecting force transmission components.

[0049] The rectangular steel pipe concrete column is formed by pouring core concrete 6 in a rectangular steel pipe 1, wherein the rectangular steel pipe 1 is formed by connecting four wall plates 1a, 1b, 1c and 1d in a certain welding order.

[0050] The inner wall of the rectangular steel pipe concrete column is welded with upper and lower mesh inner partitions distributed on the upper and lower sides, and the upper and lower mesh inner partitions are parallel to each other; H-shaped steel beams 2 are connected to the outer wall of the rectangular steel pipe concrete column. : The vertical conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com