Carbon heating smoking product and preparation method thereof

A technology for smoking products and tobacco, which is applied in the directions of tobacco, tobacco pipes, applications, etc., can solve the problems of complex production process of charcoal-heated smoking products, and achieve the effects of reducing combustion risk, reducing cost and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

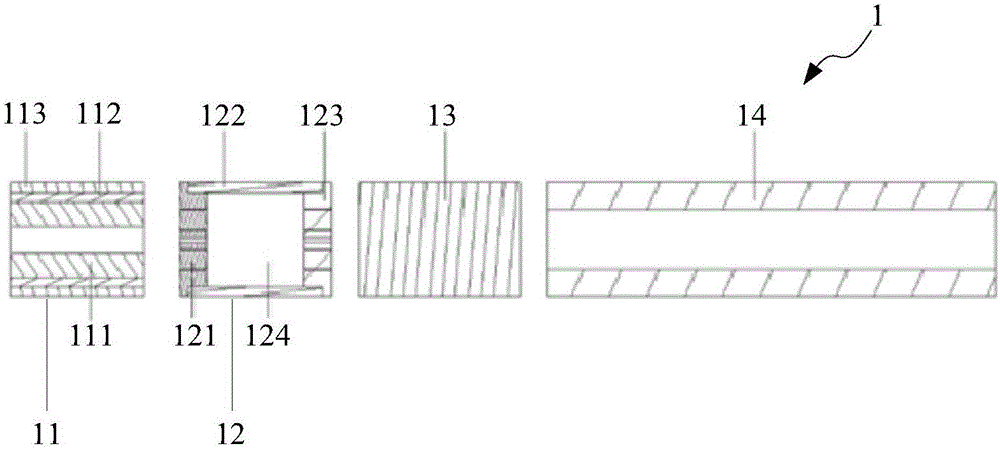

[0050] This embodiment provides a charcoal heating smoking article, the charcoal heating smoking article comprising:

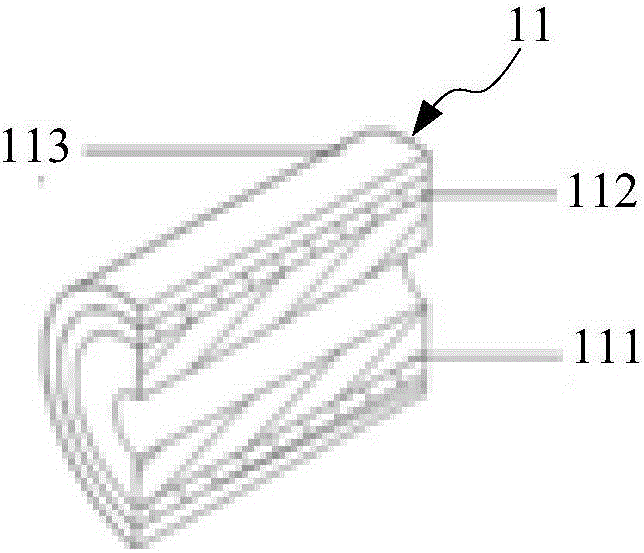

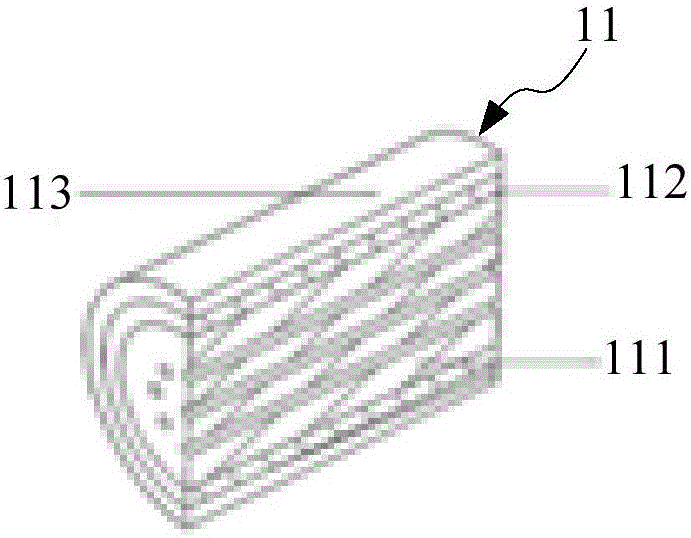

[0051] A charcoal heat source section for generating hot air by suction when the high temperature source ignites the charcoal heat source section;

[0052] a tobacco substance section for absorbing the hot air generated by the charcoal heat source section, through which the hot air vaporizes the tobacco substance in the tobacco substance section to generate smoke; the tobacco substance section includes a spacer;

[0053] Wherein, the charcoal heat source segment and the tobacco substance segment are axially arranged, and the charcoal heat source segment and the tobacco substance segment are separated by the spacer.

[0054] The charcoal heating smoking article described in this embodiment will be described in detail below with reference to figures. see figure 1 , which is a schematic cross-sectional structure diagram of a charcoal heating smoking article in ...

Embodiment 2

[0077] This embodiment provides a method for preparing a charcoal-heated smoking article based on the first embodiment. In this embodiment, the preparation method of the charcoal heating smoking article includes: the first preparation method, the second preparation method, or the third preparation method.

[0078] The first preparation method: use the tipping material to simultaneously insert the charcoal heat source section, the tobacco substance section, the cooling section, and the mouthpiece section axially in a predetermined order to form a charcoal heating smoking product. Wherein, the predetermined order is that the charcoal heat source section is connected with the tobacco substance section, the tobacco substance section is connected with the cooling section, and the cooling section is connected with the mouthpiece section.

[0079] The second preparation method: use the tipping material to connect any adjacent two sections of the charcoal heat source section, the toba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com