C-arm system rotational angle calibration device and C-arm system calibration method

A technology of rotation angle and calibration device, which is used in medical science, instruments for radiological diagnosis, diagnosis, etc., and can solve the problem of inability to calibrate the rotation angle of the C-arm system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

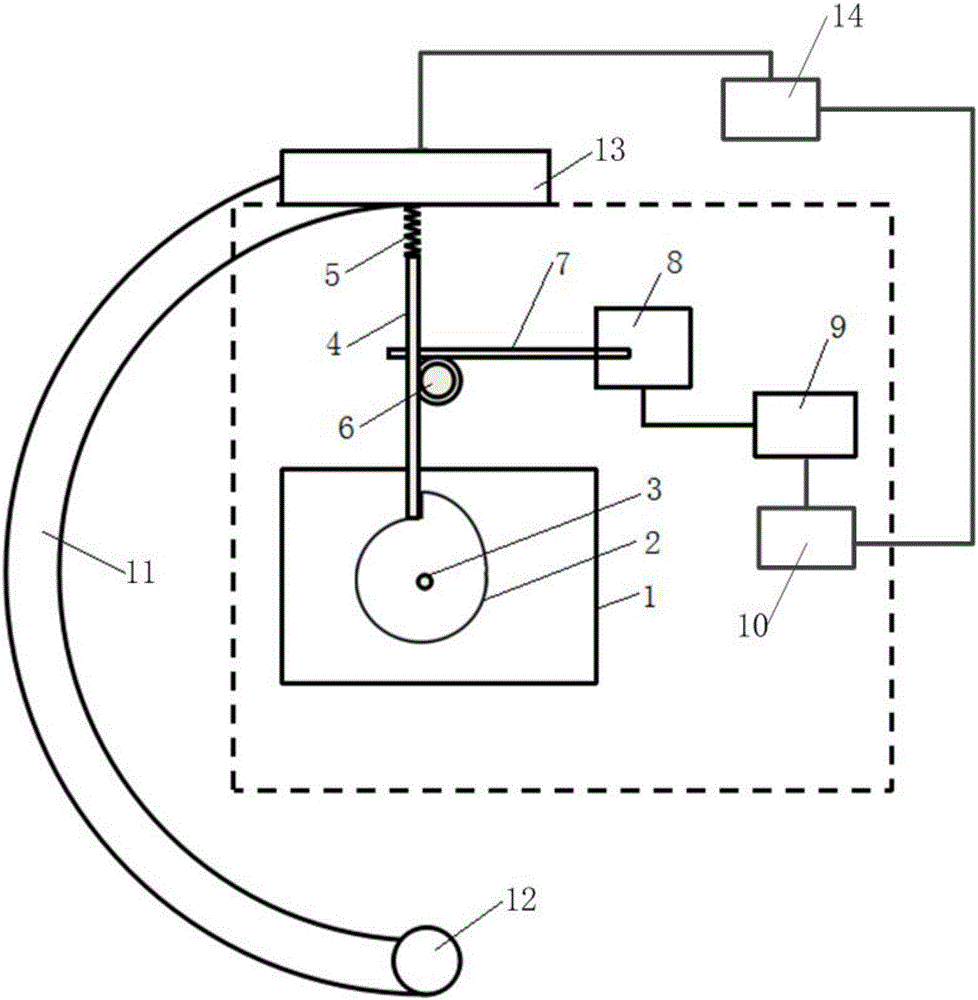

[0032] Such as figure 1 As shown, the present invention provides a C-arm system rotation angle calibration device, including: a motion conversion assembly, a displacement sensor 8 , a data transmitter 9 and a processor 10 .

[0033] The motion conversion assembly includes a base 1 , a cam 2 , a longitudinal rack 4 , a spring 5 , a transmission gear set 6 and a transverse rack 7 . The cam 2 is fixed on the base 1 through the fixed shaft 3, the fixed shaft 3 is located on the geometric center of the cam 2, and is perpendicular to the base 1, and the position of the cam 2 on the base 1 can be adjusted as required. One end of the longitudinal rack 4 is in contact with the contour of the cam 2 , and this end can move along the contour of the cam 2 , and the other end of the longitudinal rack 4 is connected with a spring 5 . The transverse rack 7 is in transmission connection with the longitudinal rack 4 through the transmission gear set 6 . The displacement sensor 8 is connected ...

Embodiment 2

[0049] For the sake of brevity, only the differences between the second embodiment and the first embodiment will be described. The difference is that the motion conversion component can also be other mechanical structures that can convert rotary motion into linear motion, such as a crank-slider mechanism Or crank linkage mechanism etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com