Split type jaw defect obturator prosthesis manufacturing method

A split type, jawbone technology, applied in the medical field, can solve the problems of poor combination effect of the occluder and removable partial denture, defective sealing effect of the occluder, difficulty in obtaining functional unity, etc. The effect of reducing the occurrence of treatment complications and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples, so as to better understand the present invention.

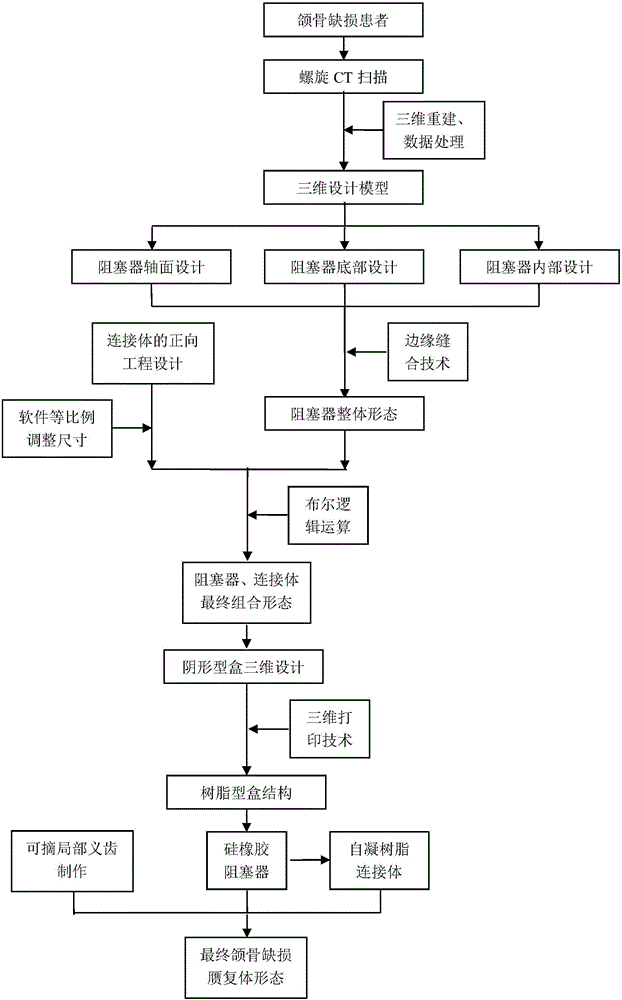

[0029] Such as figure 1 Shown, the preparation process of the embodiment of the present invention is as follows

[0030] 1) Put a cotton roll in the maxillary vestibular groove area of the patient to separate the buccal mucosa, instruct the patient not to touch the palate with the tongue and perform a spiral CT scan with the mouth slightly open. Three-dimensional reconstruction was carried out, and a three-dimensional digital model (STL format) of the patient's maxilla was obtained after point cloud denoising, triangular faceting, and surface smoothing. Segment the 3D data of the soft tissue of the patient, and extract relevant data such as the maxillary dentition, maxillary vestibule, palate, defect cavity, and nasal cavity for the 3D design of the obstructor.

[0031] 2) According to the three-dimensional data of soft and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com