Porous attapulgite adsorbent for printing and dyeing wastewater treatment and preparation method thereof

A technology of attapulgite and printing and dyeing wastewater, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the difficulty of solid-liquid separation, inability to separate sludge, and difficulty in solid-liquid separation and other problems, to achieve excellent adsorption and decolorization performance, simple and feasible treatment method, and to improve the effect of adsorption and decolorization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

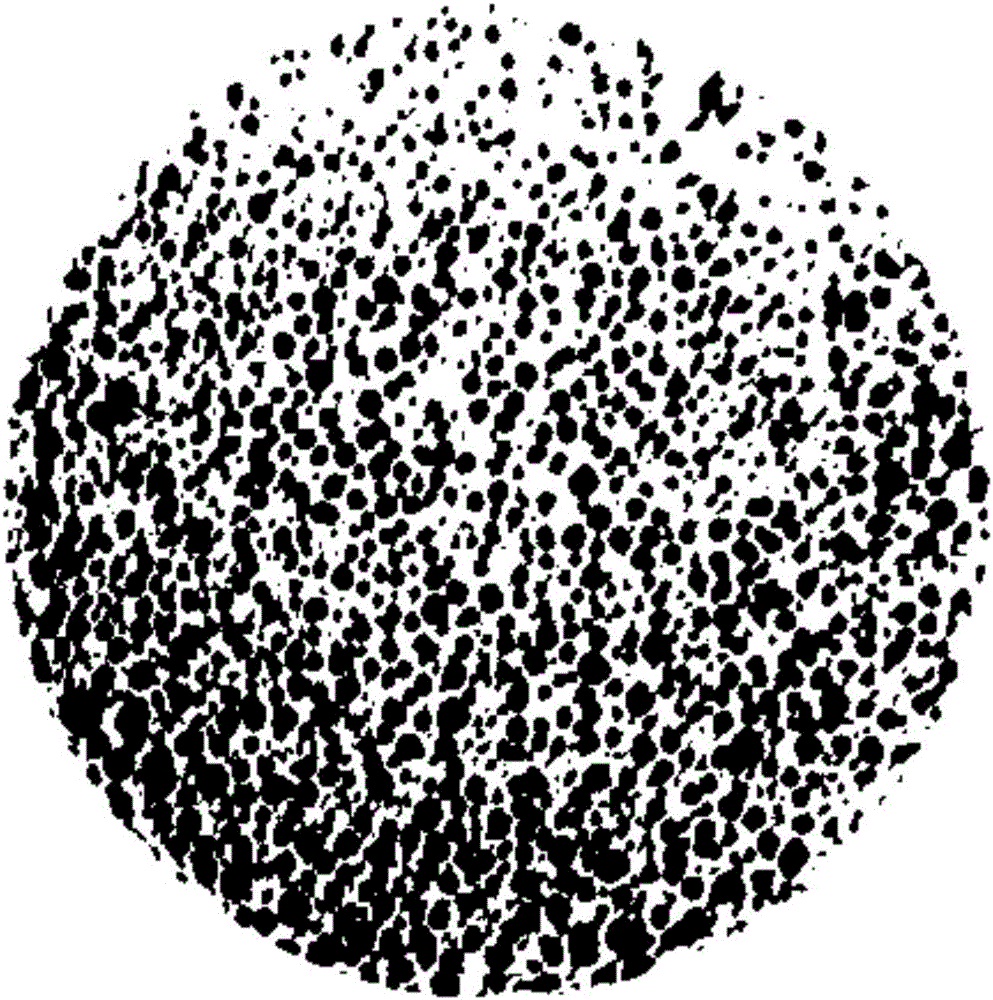

Image

Examples

Embodiment 1

[0026] Weigh 60 grams of attapulgite (100 mesh), 40 grams of β-type hemihydrate gypsum, 5 grams of sodium hexametaphosphate, 10 milliliters of hydrogen peroxide, manganese oxide MnO 2 and iron oxide Fe 2 o 3 A mixture of 0.1 g and 250 ml of water.

[0027] (1) sodium hexametaphosphate is added in water, fully dissolved, obtains uniform solution;

[0028] (2) Add attapulgite, β-type hemihydrate gypsum and manganese oxide MnO 2 with iron oxide Fe 2 o 3 mixture, stir well;

[0029] (3) Add hydrogen peroxide, stir evenly, pour the slurry into the mould, and let stand for 12 hours;

[0030] (4) The slurry and the mold are placed together in a 50°C oven for drying, demoulding, and the green body after demoulding continues to dry at this temperature;

[0031] (5) Put the dried green body into a muffle furnace for roasting, raise the temperature to 400°C at 10°C / min and keep it for 4 hours, then cool to obtain the required porous attapulgite adsorbent.

Embodiment 2

[0033] Weigh 65 grams of attapulgite (100 mesh), 35 grams of desulfurized gypsum, 5 grams of water glass, 25 milliliters of hydrogen peroxide, manganese oxide MnO 2 and chromium oxide Cr 2 o 3 A mixture of 0.5 g and 300 ml of water.

[0034] (1) Water glass is added in water, fully dissolved, obtains uniform solution;

[0035] (2) Add attapulgite, desulfurized gypsum and manganese oxide MnO 2 with chromium oxide Cr 2 o 3 mixture, stir well;

[0036] (3) Add hydrogen peroxide, stir evenly, pour the slurry into the mould, and let stand for 12 hours;

[0037] (4) The slurry and the mold are placed together in a 50°C oven for drying, demoulding, and the green body after demoulding continues to dry at this temperature;

[0038] (5) Put the dried body into a muffle furnace for roasting, raise the temperature at 10°C / min to 450°C and keep it for 3.5 hours, then cool to obtain the required porous attapulgite adsorbent.

Embodiment 3

[0040] Weigh 70 grams of attapulgite (80 mesh), 30 grams of a mixture of β-type hemihydrate gypsum and desulfurized gypsum, 5 grams of sodium hexametaphosphate, 10 milliliters of hydrogen peroxide, manganese oxide MnO 2 , chromium oxide Cr 2 o 3 and iron oxide Fe 2 o 3 A mixture of 0.1 g and 350 ml of water.

[0041] (1) sodium hexametaphosphate is added in water, fully dissolved, obtains uniform solution;

[0042] (2) Add attapulgite, a mixture of β-type hemihydrate gypsum and desulfurized gypsum, manganese oxide MnO 2 , chromium oxide Cr 2 o 3 and iron oxide Fe 2 o 3mixture, stir well;

[0043] (3) Add hydrogen peroxide, stir evenly, pour the slurry into the mould, and let stand for 12 hours;

[0044] (4) The slurry and the mold are placed together in a 60°C oven for drying, demoulding, and the green body after demoulding continues to dry at this temperature;

[0045] (5) Put the dried green body into a muffle furnace for roasting, raise the temperature to 500°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com