Preparation process of green environmentally-friendly high-adsorption-active adsorbent for printing and dyeing wastewater

A printing and dyeing wastewater, green and environmental protection technology, applied in the direction of adsorption water/sewage treatment, textile industry wastewater treatment, water/sewage treatment, etc., can solve the problem of affecting the growth of aquatic organisms and microorganisms, the adsorption activity can not meet the demand, the environment and human health threats, etc. problem, achieve excellent physical adsorption performance, simple and feasible preparation process, and solve the effect of decolorization problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

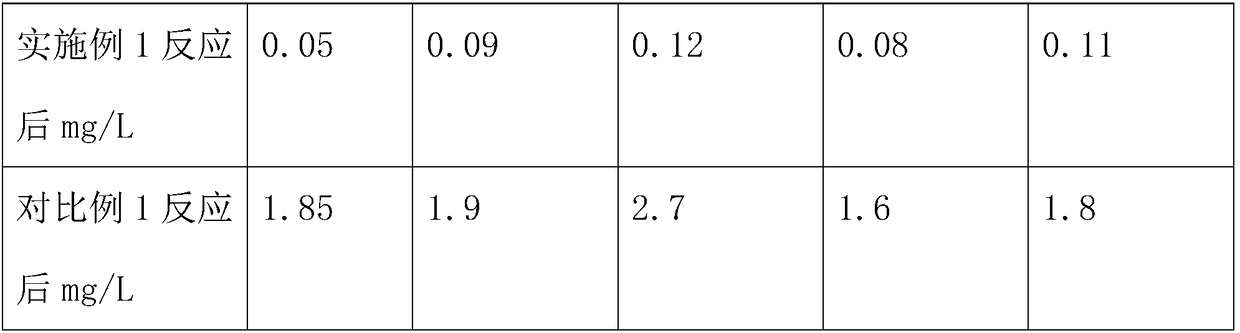

Embodiment 1

[0019] A kind of preparation technology of the adsorbent for printing and dyeing wastewater with green environmental protection and high adsorption activity comprises the following steps:

[0020] S1. Stir 30g of fly ash, 12g of bentonite, and 200g of concentrated sulfuric acid at a temperature of 65°C for 2 hours, filter, wash, and dry, add 5g of β-type hemihydrate gypsum, 1g of manganese oxide, and 3g of iron oxide and mix evenly to obtain a fly ash compound thing;

[0021] S2. Mix and stir 10g carbon nanotubes and 40g spherical alumina evenly, add 100g concentration of 48wt% ethanol solution and stir for 20min at a stirring speed of 1200r / min, add 35g microcrystalline cellulose, stir at a temperature of 130°C for 20min, filter, Washing to obtain a carbon nanotube composite;

[0022] S3. Mix 10g of sodium hexametaphosphate and 60g of water evenly, add 100g of fly ash compound and 20g of carbon nanotube compound, mix evenly, put it into a mold, dry it in an oven at a tempera...

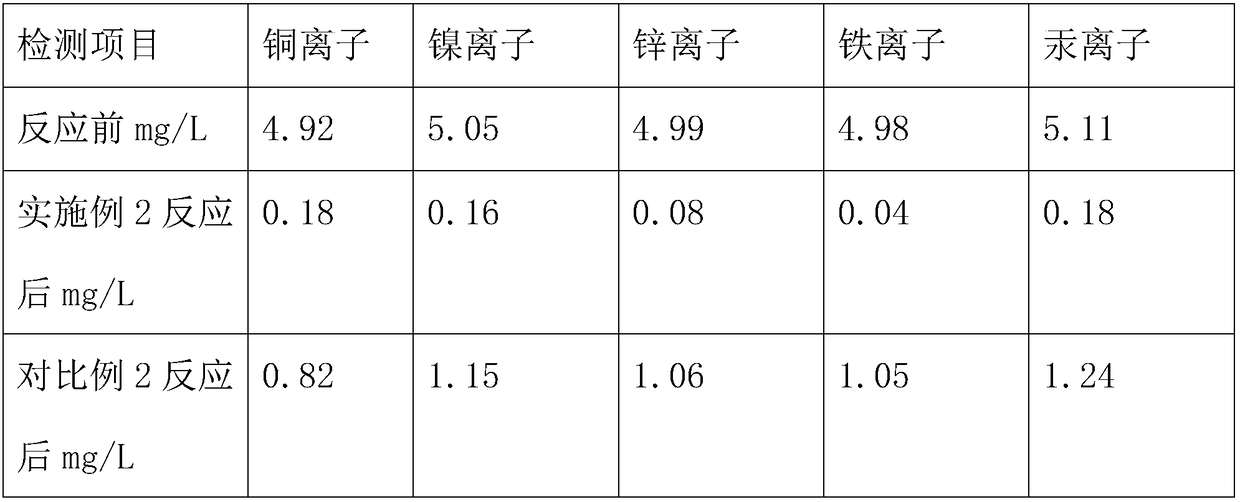

Embodiment 2

[0031] A preparation process of an environmentally friendly and highly active printing and dyeing wastewater adsorbent, comprising the following steps:

[0032] S1. Stir 50g of fly ash, 4g of bentonite, and 400g of concentrated sulfuric acid at a temperature of 45°C for 4 hours, filter, wash, and dry, add 1g of β-type hemihydrate gypsum, 4g of manganese oxide, and 1g of iron oxide and mix evenly to obtain a fly ash compound thing;

[0033] S2. Mix and stir 20g carbon nanotubes and 20g spherical alumina evenly, add 140g concentration of 40wt% ethanol solution and stir for 30min at a stirring speed of 1000r / min, add 45g microcrystalline cellulose, stir at a temperature of 120°C for 40min, filter, Washing to obtain a carbon nanotube composite;

[0034] S3. Mix 4g of sodium hexametaphosphate and 80g of water evenly, add 60g of fly ash compound and 40g of carbon nanotube compound, mix evenly, put it into the mold, dry it in an oven at a temperature of 50°C, demould, and form the m...

Embodiment 3

[0042] A kind of preparation technology of the adsorbent for printing and dyeing wastewater with green environmental protection and high adsorption activity comprises the following steps:

[0043] S1. Stir 35g of fly ash, 6g of bentonite, and 240g of concentrated sulfuric acid at a temperature of 50°C for 2.5 hours, filter, wash, and dry, add 2g of β-type hemihydrate gypsum, 1.5g of manganese oxide, and 1.2g of iron oxide and mix evenly to obtain powder coal ash compound;

[0044] S2. Mix and stir 14g carbon nanotubes and 22g spherical alumina evenly, add 110g concentration of 42wt% ethanol solution and stir for 24min at a stirring speed of 1100r / min, add 38g microcrystalline cellulose, stir at a temperature of 124°C for 25min, filter, Washing to obtain a carbon nanotube composite;

[0045] S3. Mix 6g of sodium hexametaphosphate and 63g of water evenly, add 80g of fly ash compound and 26g of carbon nanotube compound, mix evenly, put it into a mold, dry it in an oven at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com