Inorganic fireproof coating and preparation method thereof

A fire retardant coating, inorganic technology, applied in the direction of fire retardant coatings, alkali metal silicate coatings, coatings, etc., can solve the problem of inorganic fire retardant coatings do not have elimination and other problems, and achieve the advantages of wide application, easy availability of raw materials, and reduction of VOC content. and odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The second aspect of the embodiment of the present application provides a method for preparing an inorganic fireproof coating, comprising the following steps:

[0053] S01. Provide various components of inorganic fireproof coatings;

[0054] S02. Perform the first mixing, dispersing and grinding treatment of pigments, fillers and other additives with part of the water to obtain the first mixture;

[0055] S03. The formaldehyde removal agent and the first mixture are subjected to a second mixing and dispersing treatment to obtain a second mixture;

[0056] S04. The potassium silicate, odor-cleaning emulsion, formaldehyde-resistant emulsion, film-forming aid, rheological additive and the second mixture are subjected to a third mixing and dispersing treatment to obtain an inorganic fireproof coating.

[0057] The preparation method of the inorganic fireproof coating provided by the second aspect of the present application is simple and convenient, only needs to mix the pr...

Embodiment 1

[0070] Inorganic fireproof coating and preparation method thereof

[0071] Inorganic fire retardant coating

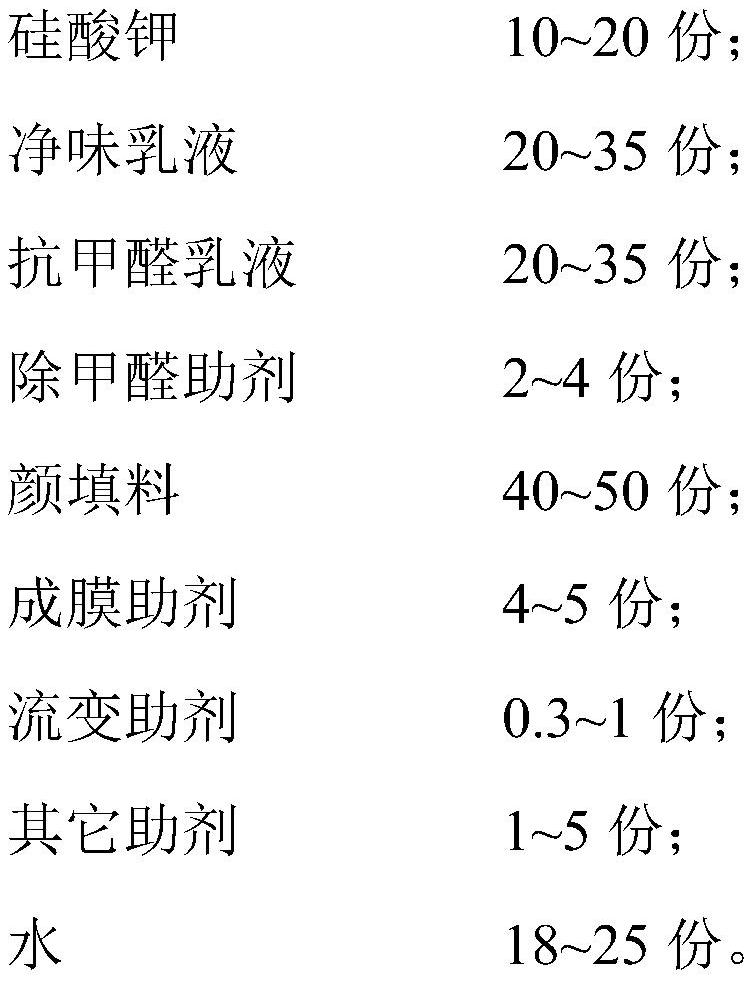

[0072] Comprising the following components by weight:

[0073]

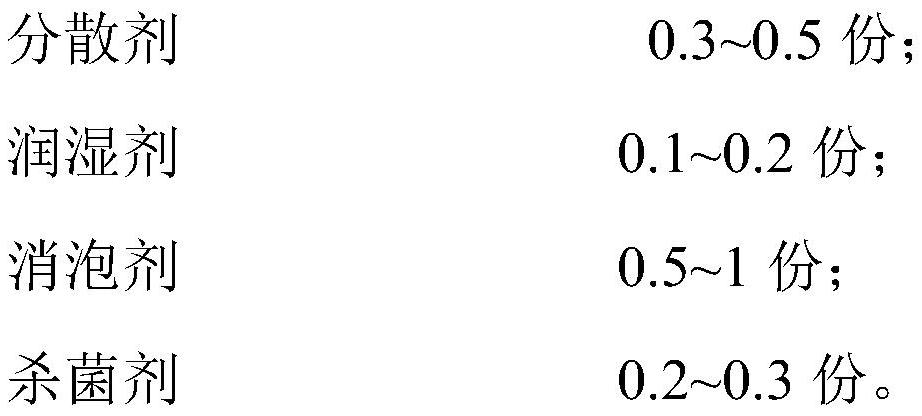

[0074] And, auxiliary agent is selected from:

[0075]

[0076] Among them, the potassium silicate is selected from potassium silicate with a modulus of 4.0; the odor-cleaning emulsion is selected from BASF 7653; the anti-formaldehyde emulsion is selected from Dow SF-105; the formaldehyde removal additive is selected from HQJ-406; the filler is selected from pentaerythritol, A mixture of melamine and ammonium polyphosphate; film-forming aids are selected from alcohol ester twelve; rheology additives are selected from RHEOLATE299; dispersants are selected from OROTAN CA2500; wetting agents are selected from BD-109 non-ionic wetting agents; defoaming The agent is selected from SN-1340 mineral oil defoamer; the bactericide is selected from Thor MBS bactericide; the pigment is selected from rutile ti...

Embodiment 2

[0083] Inorganic fireproof coating and preparation method thereof

[0084] Inorganic fire retardant coating

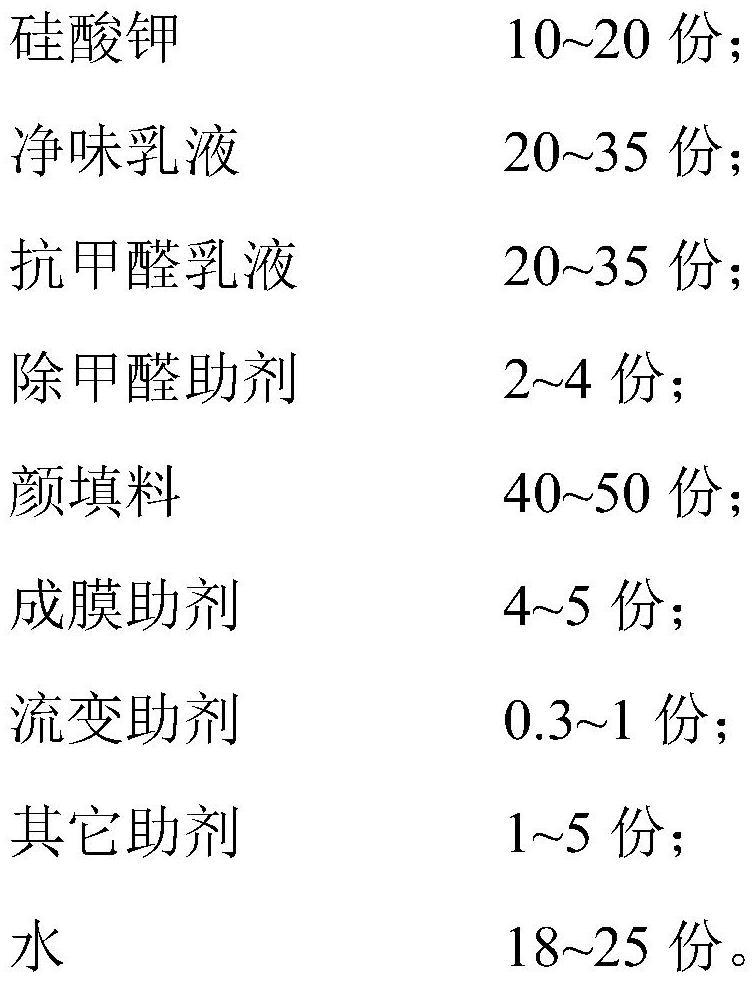

[0085] Comprising the following components by weight:

[0086]

[0087]

[0088] And, auxiliary agent is selected from:

[0089]

[0090] Among them, potassium silicate is selected from potassium silicate with a modulus of 4.0; deodorant emulsion is selected from BATF RS-5939; anti-formaldehyde emulsion is selected from Bailimo TM SF-508; formaldehyde removal additives are selected from Tongfeng TFX-1001; fillers are selected from a mixture of pentaerythritol, melamine, and ammonium polyphosphate; film-forming additives are selected from tripropylene glycol butyl ether; rheological additives are selected from RHEOLATE 299; dispersion The agent is selected from OROTANCA2500; the wetting agent is selected from BD-109 non-ionic wetting agent; the defoamer is selected from SN-1340 mineral oil defoamer; the fungicide is selected from Thor MBS fungicide; the pigm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com