High-efficiency, energy-saving and low-cost automatic cleaning machine

An automatic cleaning machine, high-efficiency and energy-saving technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as high production costs, high energy consumption, and complex structures, and achieve low labor costs, The effect of good control precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

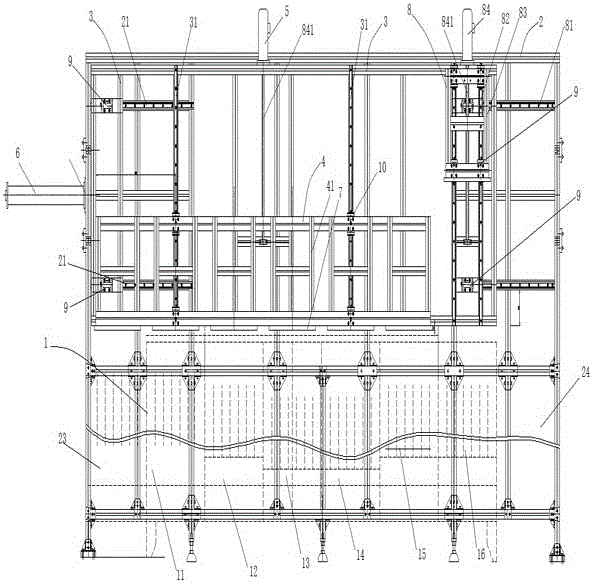

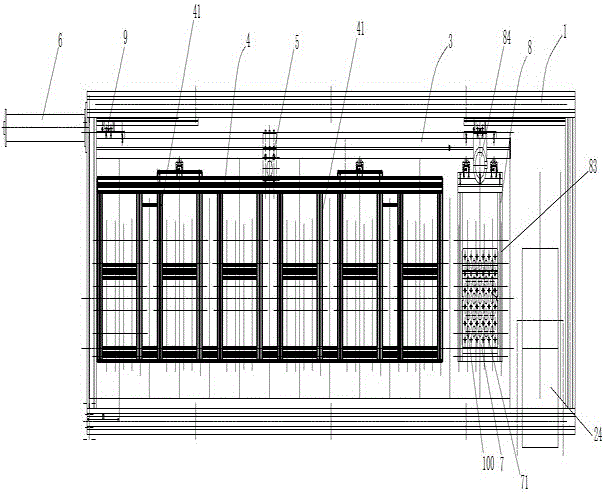

[0027] refer to Figure 1~Figure 2 , a high-efficiency, energy-saving and low-cost automatic cleaning machine according to the present invention, comprising: a plurality of cleaning tanks 1 arranged at intervals along the horizontal direction according to the cleaning sequence; a bracket 2, erected above the cleaning tank 1 along the cleaning sequence, on which At least one guide rail 21 is arranged along the horizontal direction; the cleaning frame 3 is arranged on the guide rail 21 of the support 2, and at least one slide rail 31 is arranged at intervals along the vertical direction on it; the cleaning frame 4 is arranged on the cleaning frame 3. On the slide rail 31, a number of cleaning tray grippers 41 corresponding to the number of the cleaning tanks 1 are arranged at intervals along the horizontal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com