Additive manufacturing equipment combining electron beam selective melting and electron beam cutting

A technology of additive manufacturing and selective melting, which is applied in the field of additive manufacturing and can solve the problems of inability to perform surface processing of inner channels, poor surface finish, and reducing the overall efficiency of parts manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

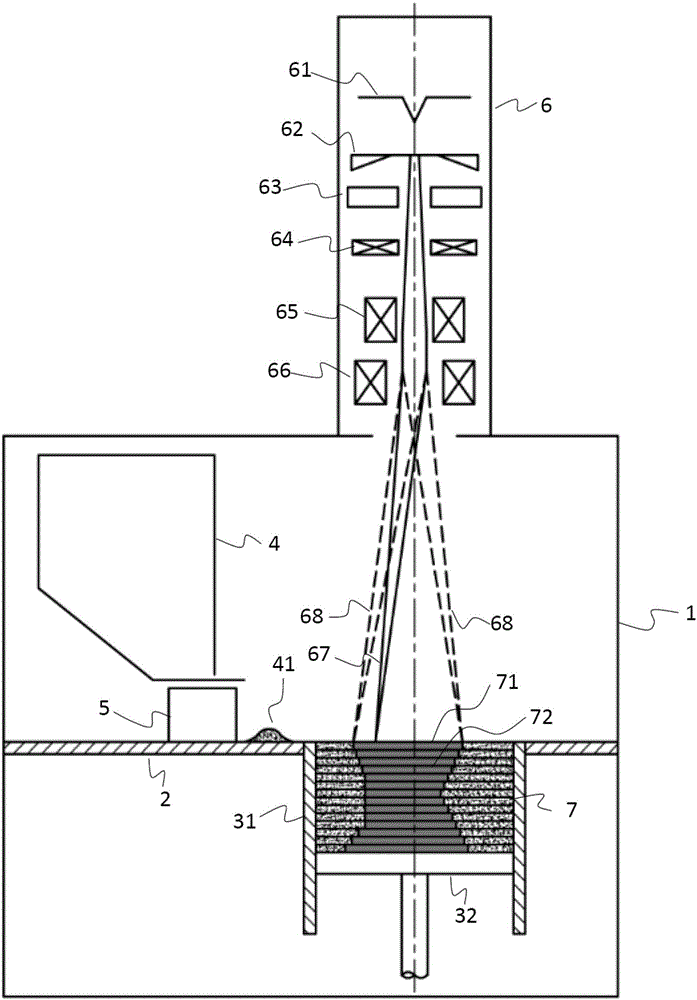

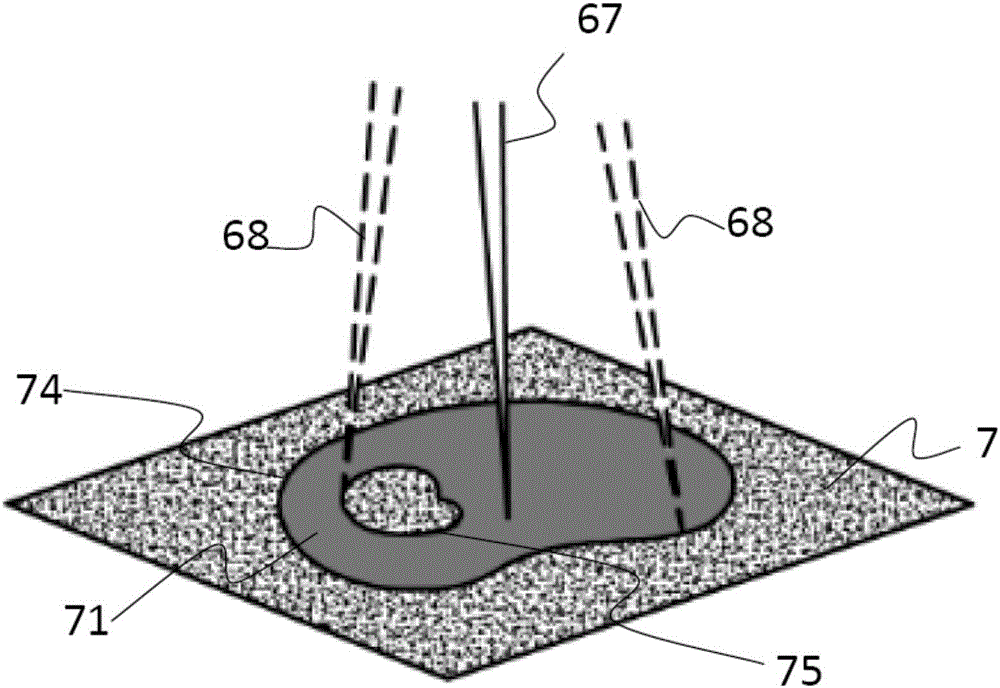

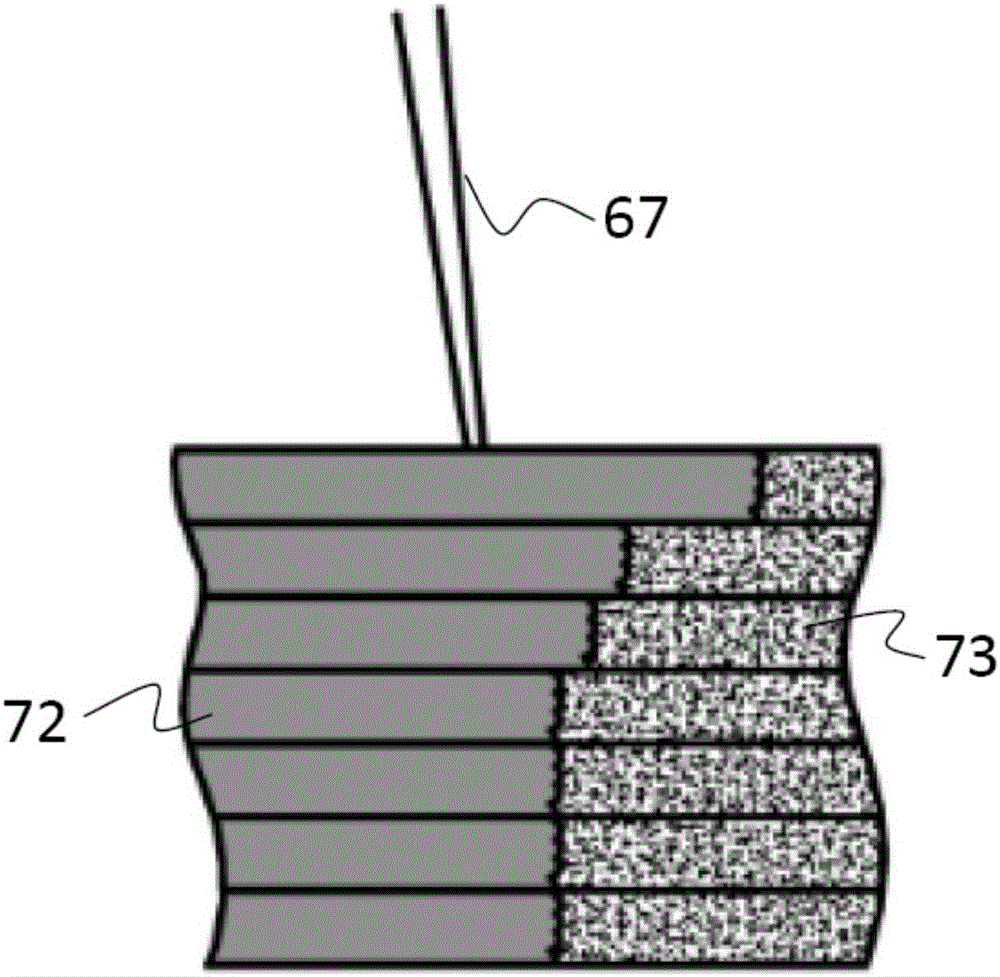

[0075] Such as figure 1 As shown, according to an embodiment of the present invention, the additive manufacturing equipment using electron beam selective melting and cutting composite includes: vacuum forming chamber 1, working platform 2, forming cylinder 31, piston type lifting device 32, powder feeder 4, A powder spreader 5, an electron beam emission focusing scanning device 6 and a control computer as a controller.

[0076] The electron beam emitting and gathering scanning device 6 includes a filament 61 generating an electron beam 67, a cathode 62, a grid 63, an anode 64, a focusing coil 65, and a deflection coil 66, which generate an electron beam 67 for scanning the forming area, heating, sintering and melting the powder , Cut the inner and outer contours of the formed material.

[0077] The vacuum forming chamber 1 provides a vacuum environment for the selective melting process, and a working platform 2 is arranged horizontally in the middle.

[0078] The powder feed...

Embodiment 2

[0090] Figure 8 with Figure 9 Shown are additive manufacturing equipment using electron beam selective melting and cutting according to other embodiments of the present invention, including multiple electron beam emission focusing scanning devices 6 for selective melting and cutting additive manufacturing equipment. Other compositions are similar to that of Example 1, and its process is also similar to that of Example 1, which will not be repeated here.

[0091] in, Figure 8 It shows the combination of two electron beam emitting and focusing scanning devices 6, the electron beams emitted by the two electron beam emitting and focusing scanning devices 6 all have three different working modes of heating, melting deposition and electron beam cutting, and the two electron beams The scanning areas of the beam emitting focusing scanning device 6 overlap only at the edge, and more than 90% of the scanning areas do not overlap each other. Two electron beam emitting and gathering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com