Steel pipe polishing device

A technology for equipment and steel pipes, applied in the field of steel pipe polishing equipment, can solve the problems of low efficiency and insufficient uniformity and effectiveness of polishing devices, and achieve the effects of simple structure, convenient use and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

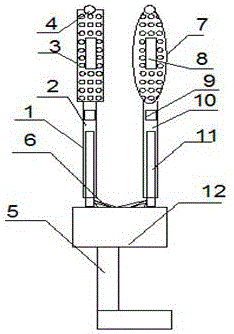

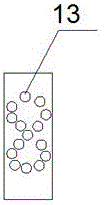

[0014] refer to figure 1 and figure 2 The steel pipe polishing equipment shown includes a steel pipe polishing equipment body 1, the steel pipe polishing equipment body 1 is provided with a polishing motor master valve 12; the polishing motor master valve 12 is provided with a polishing handle 5; The polishing motor main valve 12 is provided with a rotating roller 2; the front end of the rotating roller 2 is provided with a polishing bristle 3; one side of the rotating roller 2 is provided with an outer throwing roller 10; the outer throwing roller 10 A clamping spring 6 is arranged between the rotating roller 2; an outer throwing brush 7 is arranged on the outer throwing roller 10; a symmetrical magnet 8 is arranged between the outer throwing brush 7 and the polishing bristles 3; The outer throwing brush 7 and the polishing bristles 3 are all provided with polishing wheels 13; the polishing wheels 13 are arranged in a figure-eight shape.

[0015] As a preferred technical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com