Door sheet cutting saw

A technology for cutting saws and door panels, applied in the direction of saw blades, circular saws, etc., can solve problems such as heat dissipation difficulties of saw blades, and achieve the effect of solving heat dissipation difficulties and realizing automatic replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

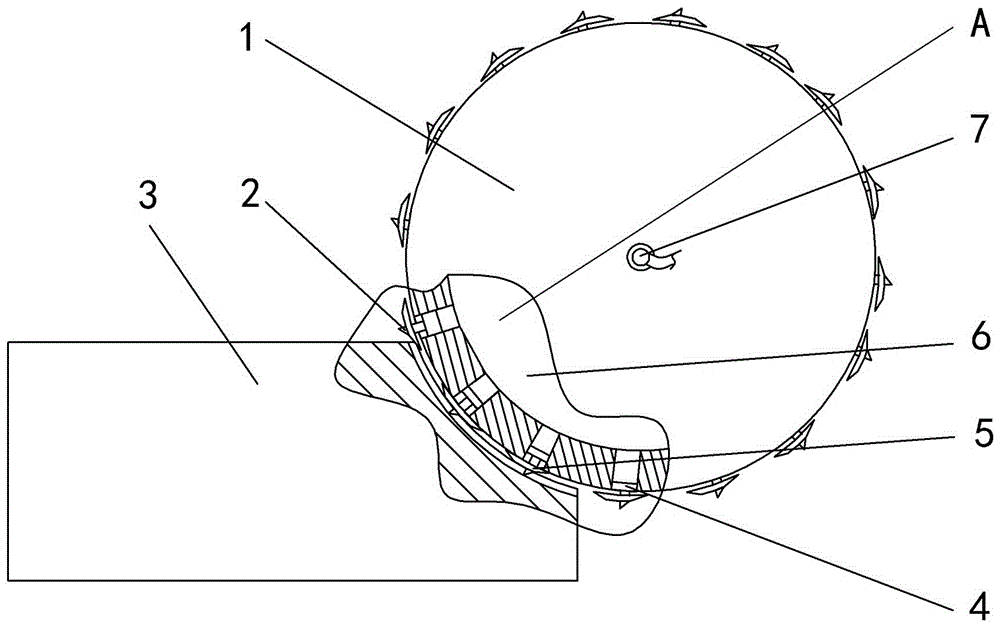

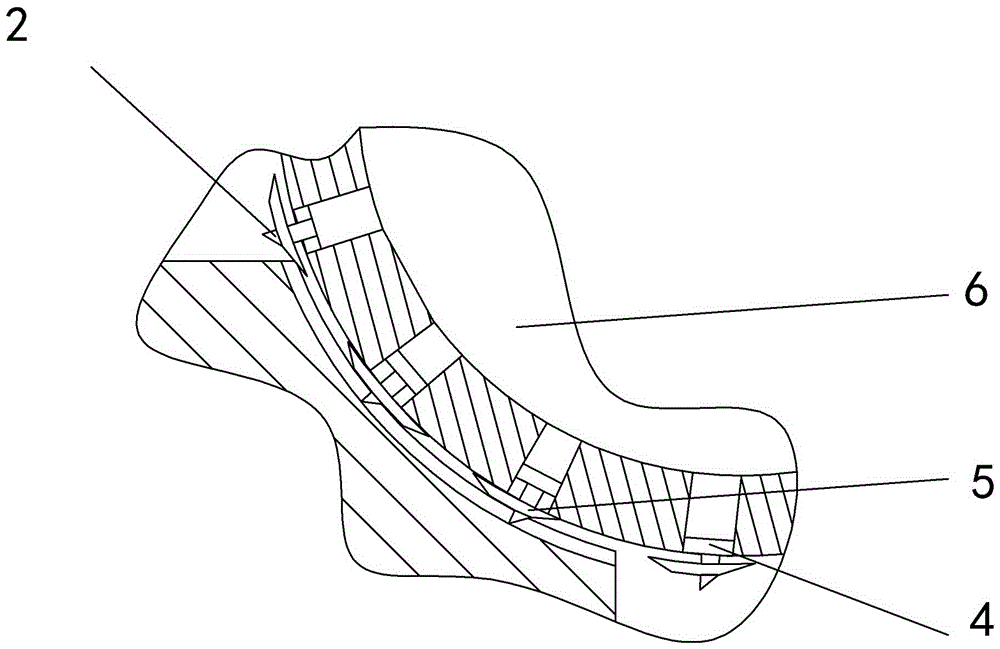

[0015] Embodiment: the door panel cutting saw in this scheme, as figure 1 As mentioned above, it includes a motor, a disc 1, a liquid storage tank and several sawtooth 2 units, the center of the disc 1 is connected to the output end of the motor, and the sawtooth 2 units are evenly distributed on the circumference of the disc 1. A cavity 6 is processed in the disc 1, the cavity 6 is in a spiral shape, the cavity 6 communicates with the liquid storage tank, and a one-way valve from the liquid storage tank to the cavity 6 is installed between the cavity 6 and the liquid storage tank. An accumulator is installed in the liquid tank, and a liquid filling pump for replenishing coolant is connected to the liquid storage tank. An overflow valve is installed in the cavity 6, and the overflow valve is located at the center of the disc 1. The overflow valve is provided with a universal joint 7, and the universal joint 7 is connected with a hose, and the hose leads to the liquid receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com