Simple concrete column maintaining device

A simple technology for concrete columns, which is applied in the field of simple concrete column maintenance devices, can solve the problems of package material damage and fragmentation, complicated installation, complicated position, etc., and achieve the effect of convenient operation, simple manufacture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

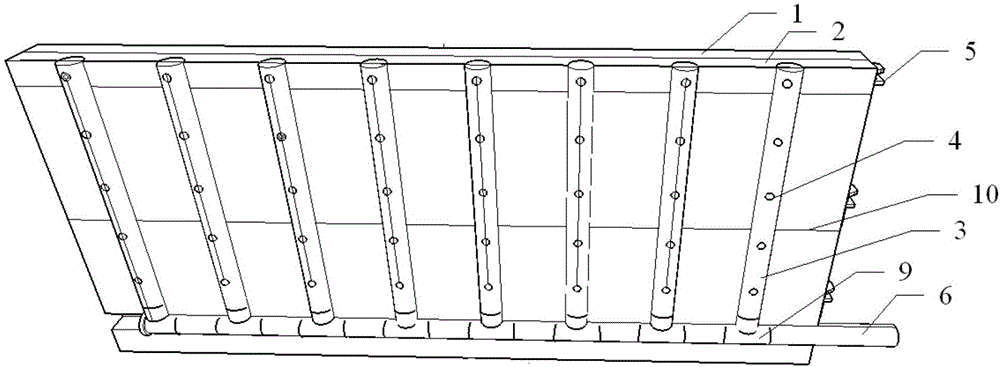

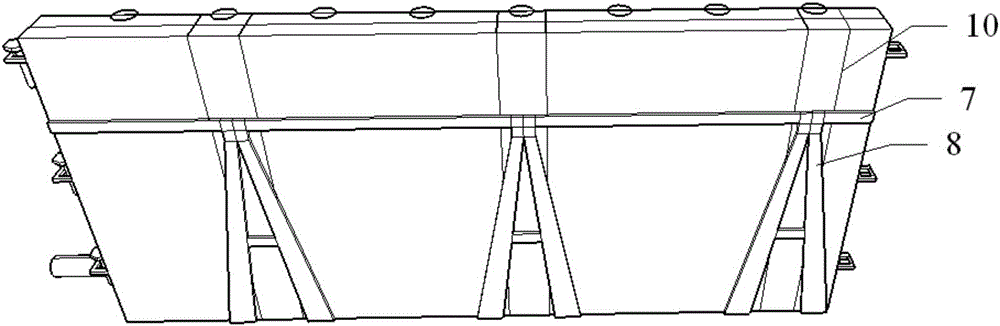

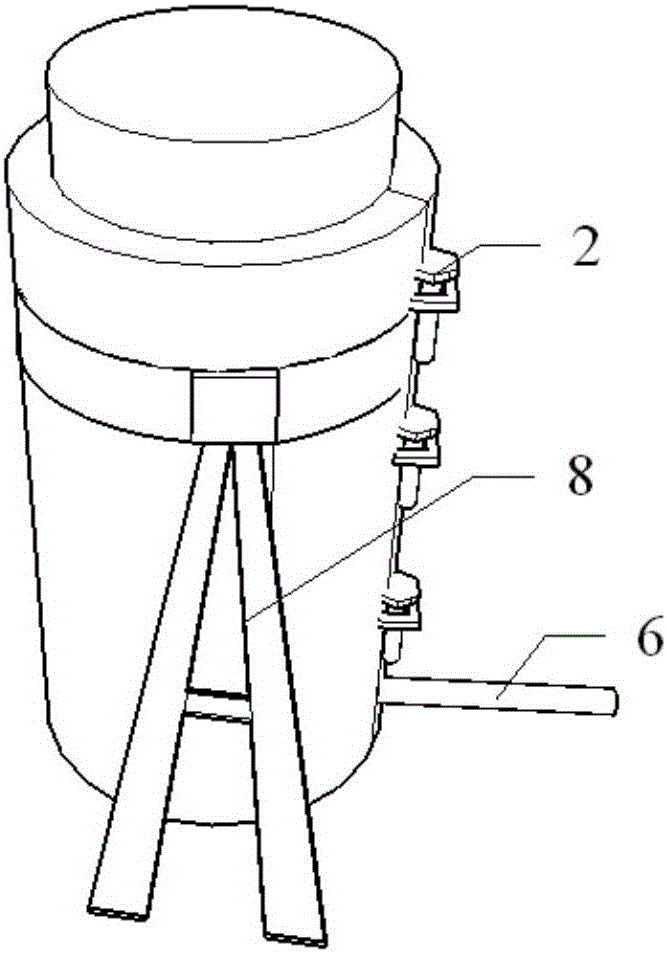

[0016] refer to Figure 1-Figure 4 , the present invention includes an outer tarpaulin insulation layer 1, a felt water-retaining layer 2, a water spray pipe 3 and a flexible water inlet pipe 4, and the water spray pipe 4 is vertically connected to the felt water-retaining layer 2 at even intervals, and the flexible water inlet pipe 6 is connected to all water spray pipes The bottom of the pipe 3 is connected, and the surface of the water spray pipe has a water spray hole 4. Two buckles 5 are sewn on the plastic tarpaulins at both ends of the device. After the maintenance device is installed, it is fixed with long bolts and nuts. The outer tarpaulin insulation layer , the felt water-retaining layer and the flexible water inlet pipe are sewn and fixed into a curtain-like whole with nylon rope 10. The flexible water inlet pipe for several days adopts a steel wire stiffened hose, which can surround the maintenance column without the phenomenon of concavity and ensure the normal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com