Tobacco box positioning and error-preventing control system and method in tobacco primary processing tobacco box unpacking process

A control system and error prevention technology, which is applied in the field of cigarette box positioning error prevention control system in the unboxing process of tobacco shredded cigarette boxes, can solve the problems of false triggering, cigarette pack falling off, and lifting motor overload, etc., and achieves simple control logic and low cost. The effect of low investment and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and embodiments.

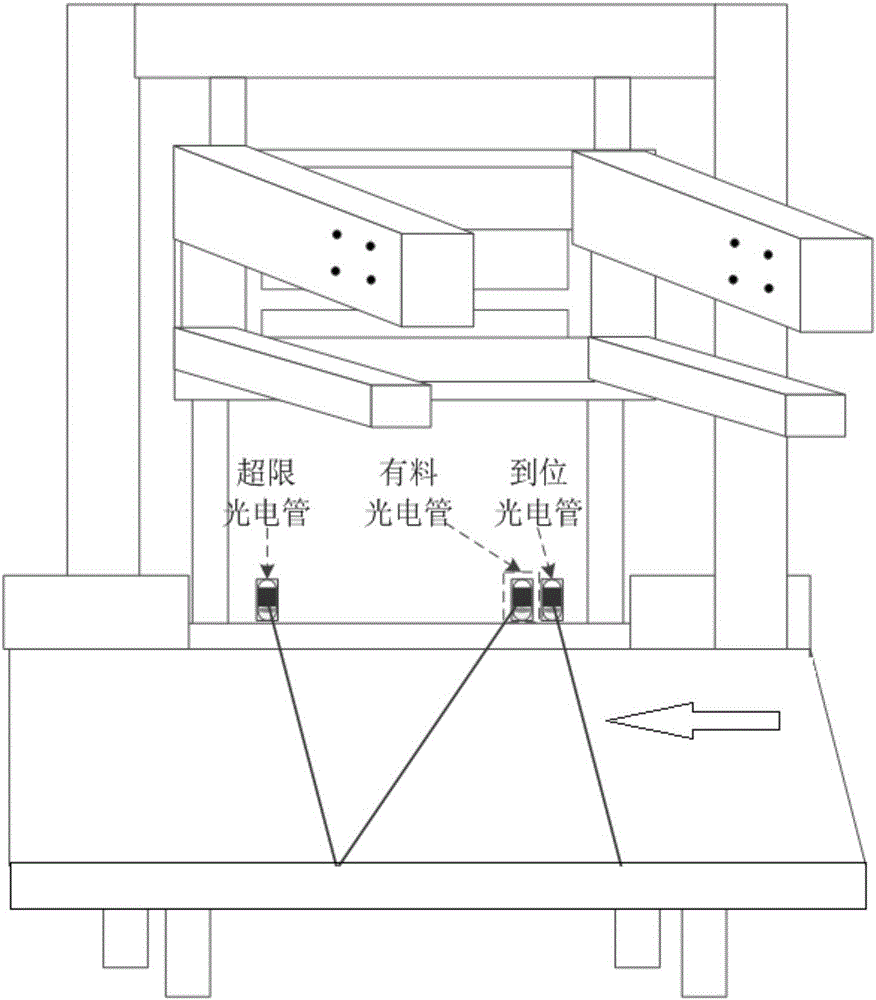

[0021] Such as figure 1 As shown, add a cigarette pack material detection phototube at the side of the conveyor belt of the clamp arm under the unloader, and use the cigarette pack in-position photoelectric tube falling edge and the cigarette pack material signal as the cigarette pack in-place judgment condition. When the cigarette pack is transported, If the photoelectric tube of the cigarette pack in place is triggered by mistake, the signal condition of the cigarette pack material is not available, the clamp arm of the unloader will not fall, and the unloader will not reverse and return. Only two signals are available at the same time, the clamp arm of the unloader Then it will descend and the box-turning machine will perform reverse action.

[0022] By adding a diffuse reflection photoelectric tube on the side of the belt of the unpacking machine, and using the signal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com