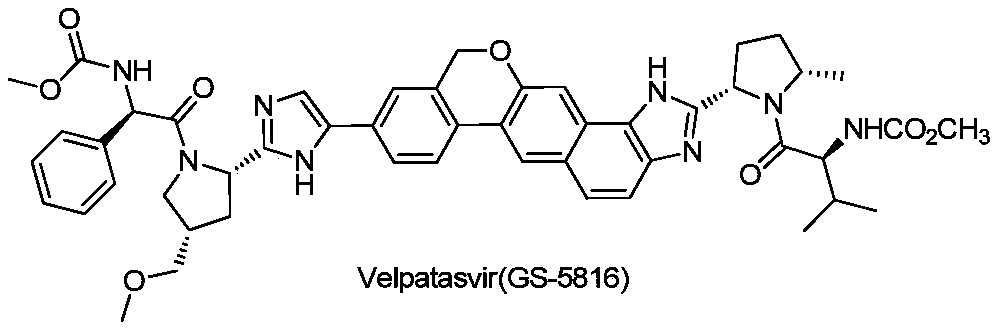

Preparation of velpatasvir and its derivatives

A technology of velpatasvir and derivatives, which is applied in the field of drug synthesis, and can solve the problems of difficult industrialization, many side effects, and high cost of velpatasvir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

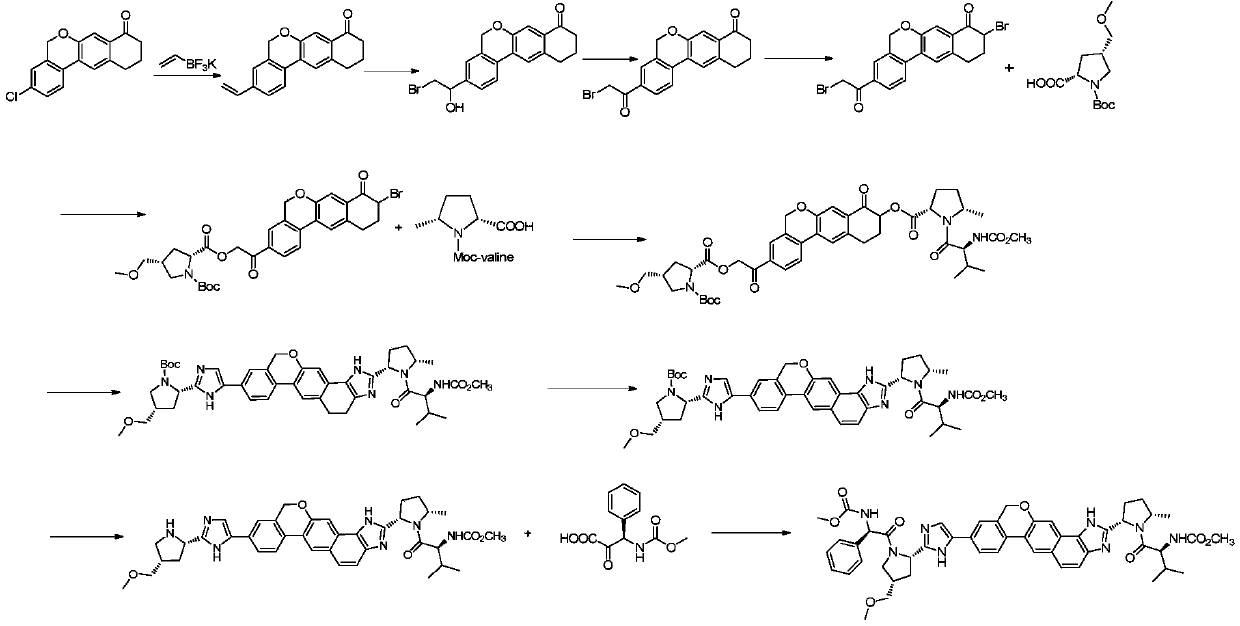

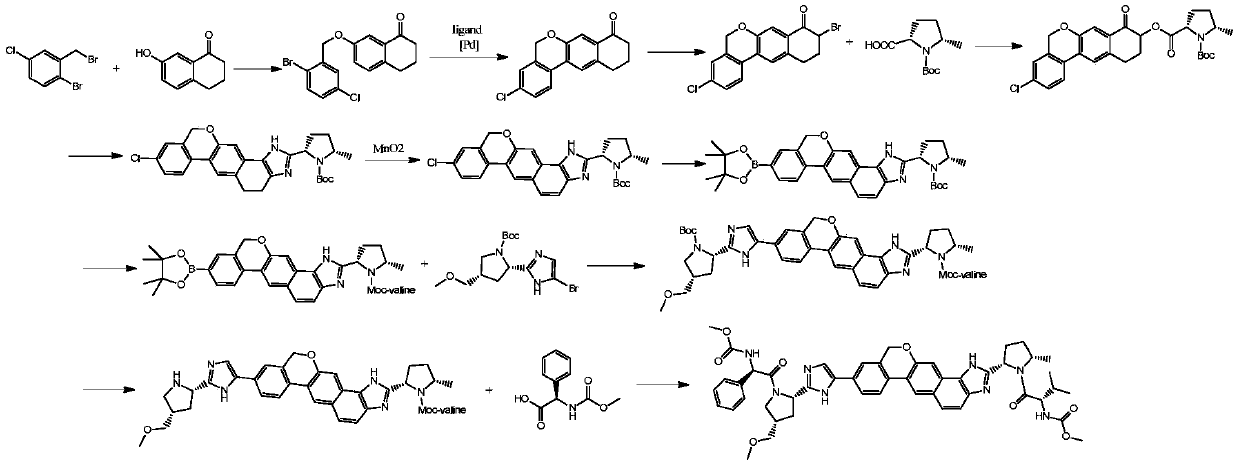

[0087] The preparation of formula 1 compound

[0088] The inventor realizes by following technical scheme (shown in route four):

[0089]

[0090] In the method of the present invention, the compound of formula 5 is prepared by condensation of the compound of formula 7 and the compound of formula 6 under alkaline conditions; the compound of formula 5 is subjected to ring closure reaction with ammonia or its derivatives at high temperature to prepare the compound of formula 4; the compound of formula 4 and Substituting reagents, carbonyl α-position substitution occurs, and the compound of formula 3 is obtained; the compound of formula 3 is condensed with compound 8 under alkaline conditions to obtain the compound of formula 2; the compound of formula 2 undergoes ring closure reaction with ammonia or its derivatives at high temperature , to prepare the compound of formula 1; the compound of formula 1 is oxidized or oxidized-deprotected to obtain VLP-1, and VLP-1 is condensed ...

Embodiment 1

[0127] Embodiment 1: synthetic compound 5a

[0128]

[0129] Add 3.7g of compound 7, 2.85g of compound 6a, 2.76g of potassium carbonate, and 55.5ml of dichloromethane into a 100ml reaction flask, heat to 30-35°C, stir for 16 hours, monitor the disappearance of the reaction material 7 by LC, add water to quench reaction. The reaction mixture was washed with water, dried over sodium sulfate, and concentrated to obtain compound 5a (5.68 g, purity 96.58%, yield 100%).

Embodiment 2

[0130] Embodiment 2: synthetic compound 5b

[0131]

[0132] Add 3.7g of compound 7, 3.3g of compound 6b, 2.76g of potassium carbonate, and 55.5ml of dichloromethane into a 100ml reaction flask, heat to 30-35°C, stir for 16 hours, LC monitors that the reaction material 7 disappears, and add water to quench reaction. The reaction mixture was washed with water, dried over sodium sulfate, and concentrated to obtain compound 5b (5.45 g, yield 98%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com