A kind of al-mg-si-cu-pr-nd rare earth aluminum alloy cable material and preparation method thereof

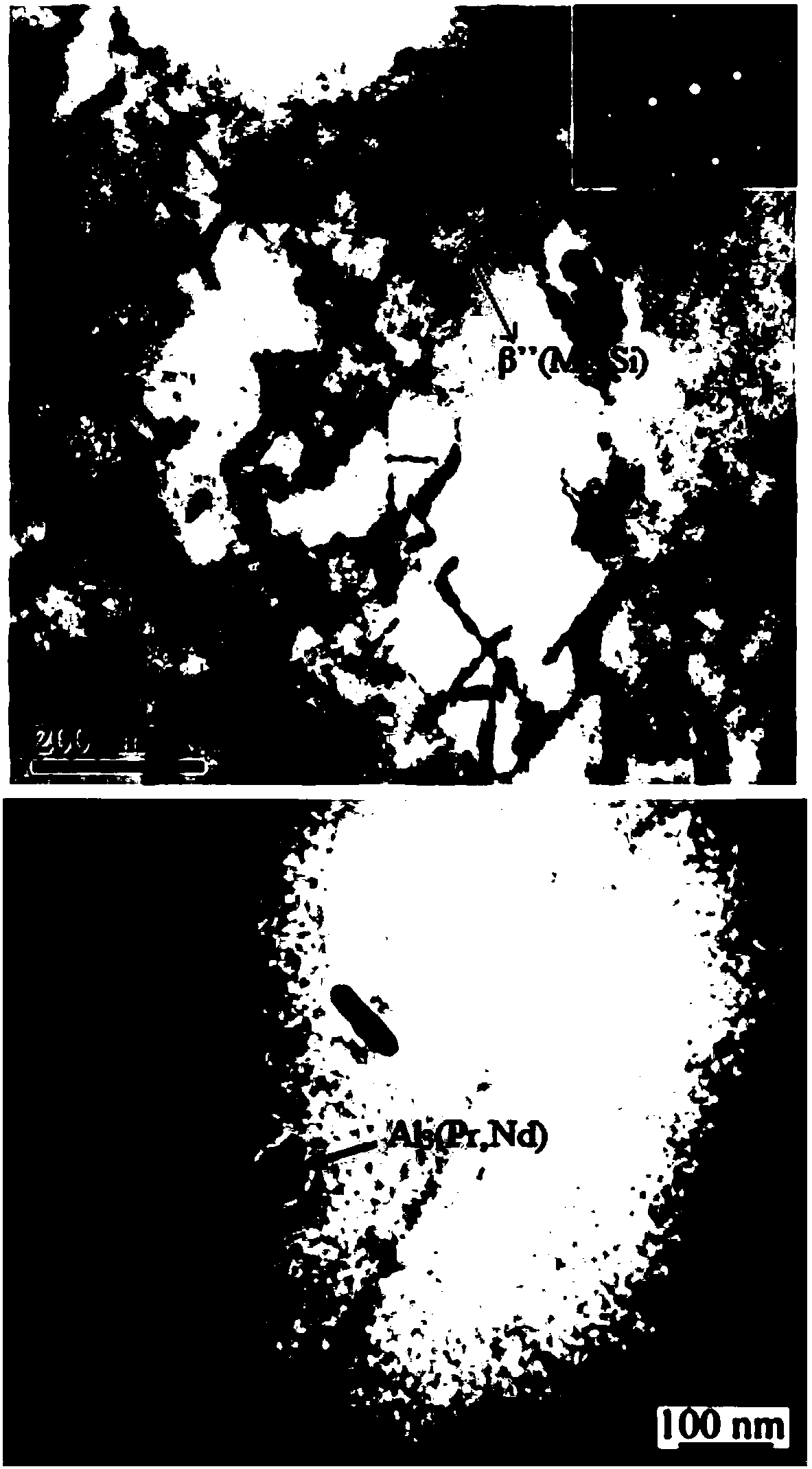

An aluminum alloy and rare earth technology, applied in the field of medium-strength rare earth aluminum alloy cable materials, to achieve the effects of improving tensile strength and elongation, excellent electrical conductivity, and reducing lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Mg: 1.7wt%, Si: 1.2wt%, Cu: 2.4wt%, Pr: 0.5wt%, Nd: 0.6wt%, and the balance is Al according to the weight percentage of the constituent elements. The above materials are smelted at a high temperature in a smelting furnace at a temperature of 750°C until they are melted;

[0037] (2) Add refining agent (20wt%NaCl+20wt%KCl+35wt%NaF+25wt%LiF) according to the mass ratio of refining agent to smelting ingredients of 1:100 for degassing, then let stand for 10min;

[0038] (3) Pouring the alloy melt into a cylindrical mold in an electromagnetic stirring device, performing low-frequency electromagnetic stirring at 15 Hz for 30 s, and then water-cooling to become an ingot;

[0039] (4) Squeeze and draw the cast ingot, the extrusion temperature is 470°C, and the wire diameter after drawing is 6mm;

[0040] (5) Heat treatment (solid solution + aging) on the wire after drawing: 530°C / 10h+165°C / 6h, heat treatment is used to prepare aluminum alloy cable materials.

Embodiment 2

[0042] (1) Mg: 1.8wt%, Si: 1.2wt%, Cu: 2.6wt%, Pr: 0.6wt%, Nd: 0.7wt%, and the balance is Al according to the weight percentage of the constituent elements. The above materials are smelted at a high temperature in a smelting furnace at a temperature of 760°C until they are melted;

[0043] (2) Add refining agent (20wt% NaCl+20wt% KCl+35wt% NaF+25wt% LiF) according to the mass ratio of refining agent and smelting ingredients in the ratio of 2:100 for degassing, then let it stand for 10 minutes;

[0044] (3) Pouring the alloy melt into a cylindrical mold in an electromagnetic stirring device, performing low-frequency electromagnetic stirring at 20 Hz for 30 s, and then water-cooling to become an ingot;

[0045] (4) Squeeze and draw the cast ingot, the extrusion temperature is 480°C, and the wire diameter after drawing is 6mm;

[0046] (5) Heat treatment (solid solution + aging) on the wire after drawing: 540°C / 20h+170°C / 6h, heat treatment is used to prepare aluminum alloy cab...

Embodiment 3

[0048] (1) Mg: 1.9wt%, Si: 1.3wt%, Cu: 2.4wt%, Pr: 0.6wt%, Nd: 0.6wt%, and the balance is Al according to the weight percentage of the constituent elements. The above materials are smelted at a high temperature in a smelting furnace at a temperature of 770°C until they are melted;

[0049] (2) Add refining agent (20wt%NaCl+20wt%KCl+35wt%NaF+25wt%LiF) according to the mass ratio of refining agent to smelting ingredients of 1:100 for degassing, then let stand for 10min;

[0050] (3) Pouring the alloy melt into a cylindrical mold in an electromagnetic stirring device, performing low-frequency electromagnetic stirring at 25 Hz for 30 s, and then water-cooling to become an ingot;

[0051] (4) Squeeze and draw the cast ingot, the extrusion temperature is 490°C, and the wire diameter after drawing is 6mm;

[0052] (5) Heat treatment (solid solution + aging) on the wire after drawing: 550°C / 22h+175°C / 6h, heat treatment is used to prepare aluminum alloy cable materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com