Electric pull lock of automobile tail door

A tailgate and electric technology, which is applied in electric locks, vehicle locks, building locks, etc., can solve the problems of loose tailgate closing, large cable deformation, and loud noise, and achieve high transmission efficiency, long service life, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described below according to the drawings and specific embodiments.

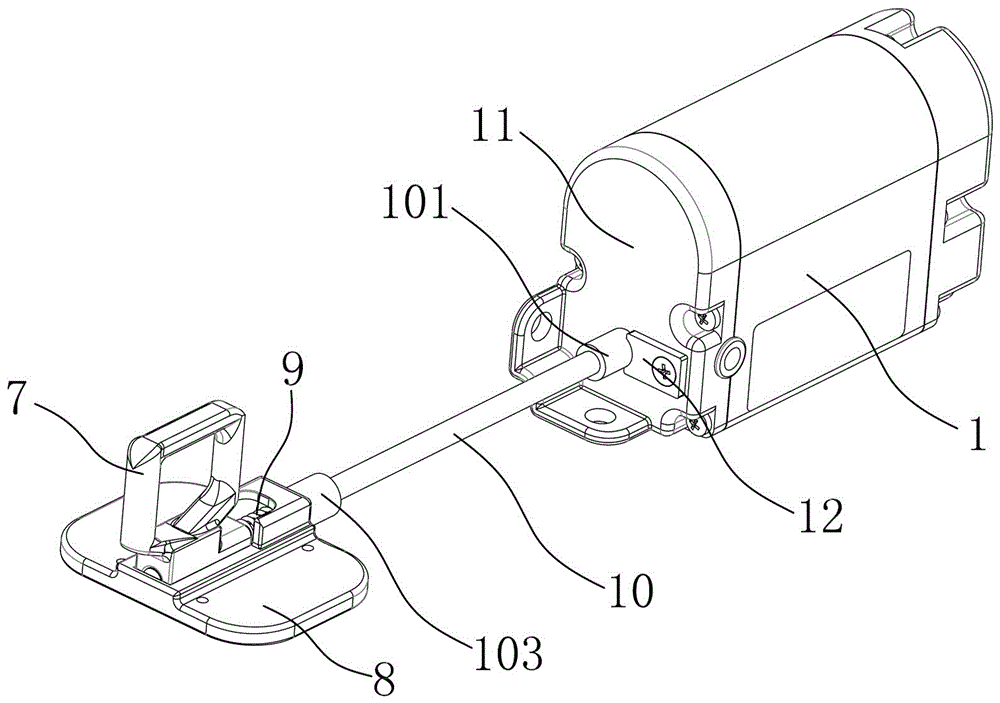

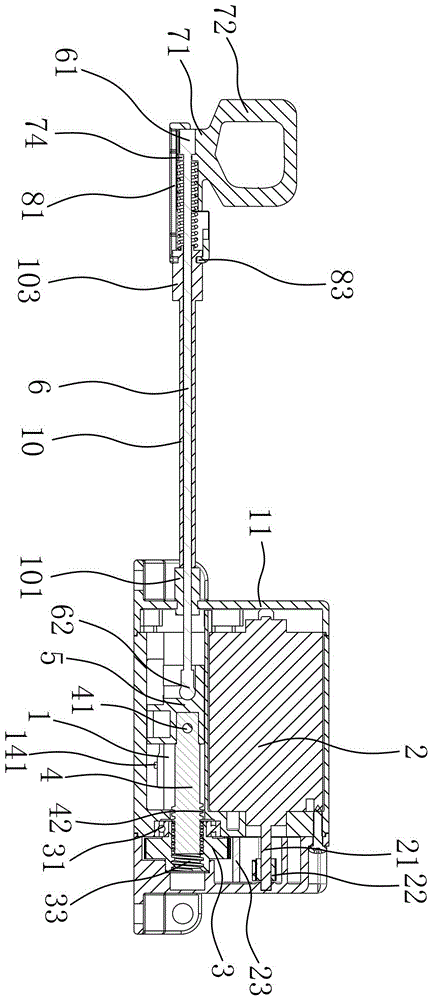

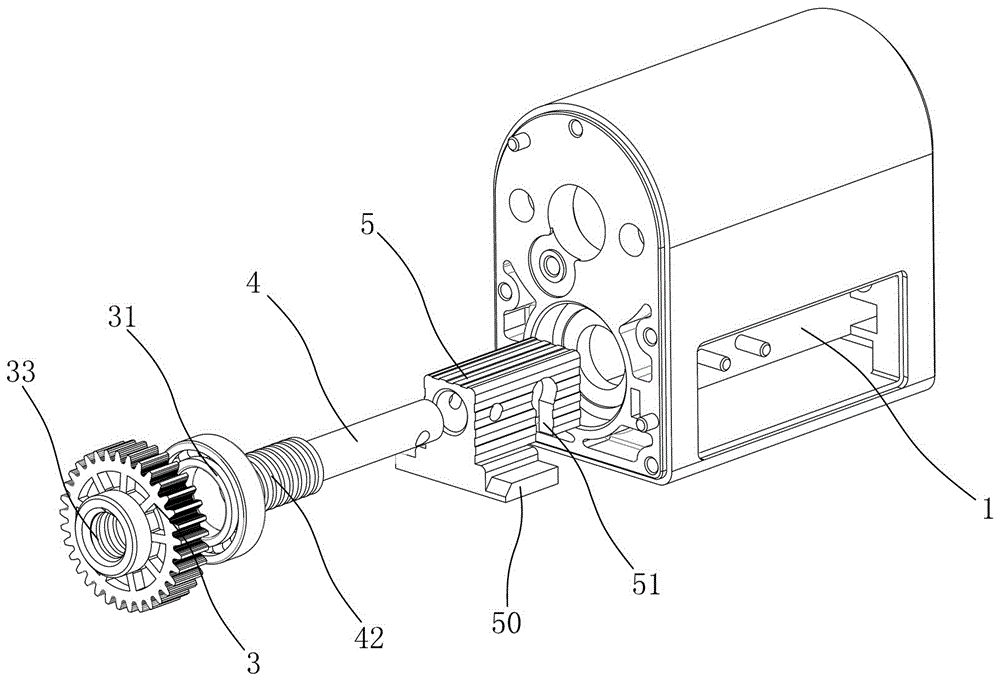

[0037] Depend on figure 1 , figure 2 , image 3 As shown, a kind of automobile tailgate electric zipper of the present invention comprises housing 1, and housing 1 is provided with driving mechanism, and driving mechanism comprises driving motor 2, linkage gear 3, screw mandrel 4 and slide block 5, and driving motor 2 The output shaft 21 is fixed with an output gear 22, the output gear 22 is linked with the linkage gear 3 through the reduction gear, the reduction gear is fixed with the housing or the motor end cover through a rotating shaft 23, the axis of the output gear 22, the axis of the reduction gear and the linkage The axes of the gears 3 are arranged parallel to each other. The interlocking gear 3 is fixed in the housing 1 through the bearing 31, the interlocking gear 3 is formed with a through hole, the outer wall of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com