Wellhead sealing device for fishing oil and its sealing method for oil fishing

A sealing device and oil wellhead technology, which is applied in sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve the problems of frequent packing replacement, heavy work intensity of workers, and environmental pollution, so as to prevent leakage Oil phenomenon, reduce labor intensity, and prevent waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

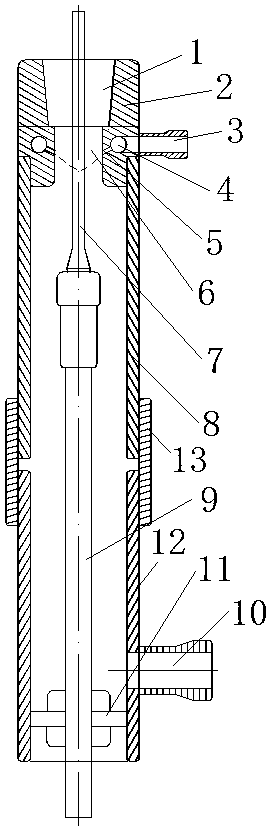

[0028] like figure 1 As shown, the present invention includes a casing 12 communicated with the oil well, the top of the casing 12 is sealed and fixed with a short pipe 8 through a collar 13, and a packing box 2 is fixed at the top of the short pipe 8. A packing 1 is fixed inside the packing box 2, and a sucker rod 9 is movably connected to the casing 12 along the axis of the casing 12, and a pumping rubber cartridge 11 is fixed on the upper part of the side wall of the sucker rod 9, so that The top of the sucker rod 9 is connected to one end of the steel cable 7, and the bottom of the sucker rod 9 is provided with a counterweight (not shown in the drawings), and the other end of the steel cable 7 passes through the set of the packing 1. After the through hole, it is connected with the hoisting device, and the upper part of the outer wall of the casing 12 is provided with an oil outlet pipe 10, and the oil outlet pipe 10 communicates with the inside of the casing 12, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com