Four-level W-shaped high pressure compressor

A high-pressure compressor, two-stage compression technology, applied in multi-stage pumps, mechanical equipment, machines/engines, etc., can solve the problems of low volume utilization and no pressure ratio drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the four-stage W-type high-pressure compressor of the present invention will be further described below in conjunction with the accompanying drawings.

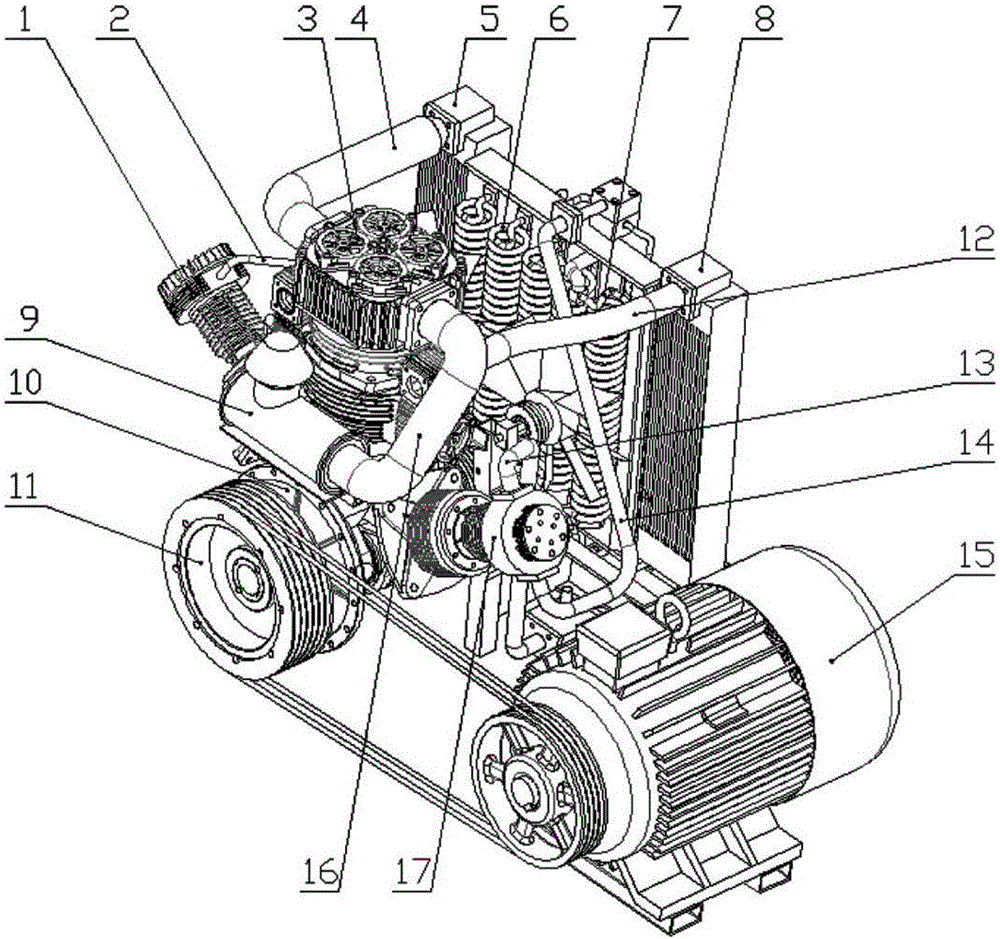

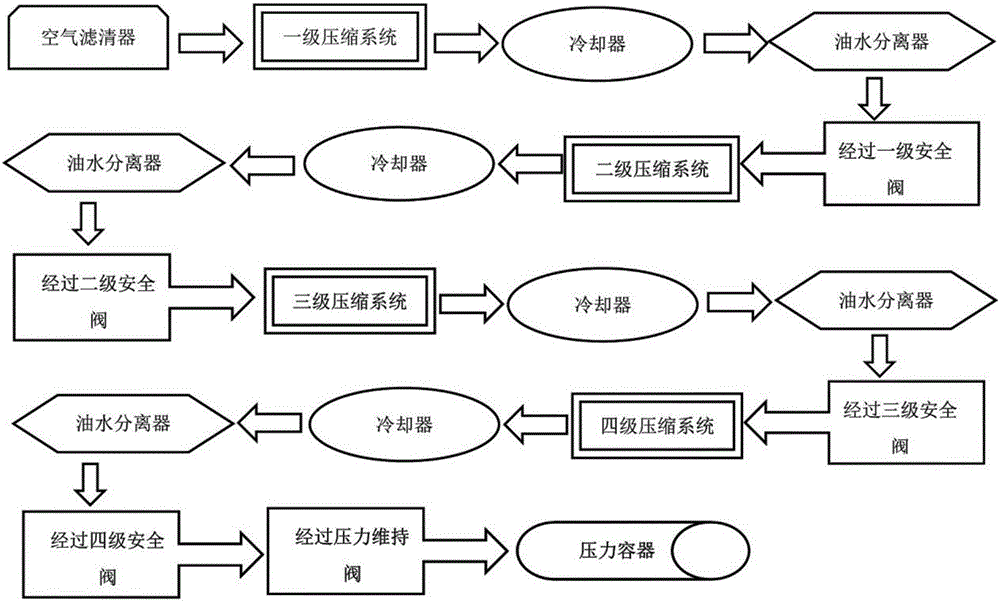

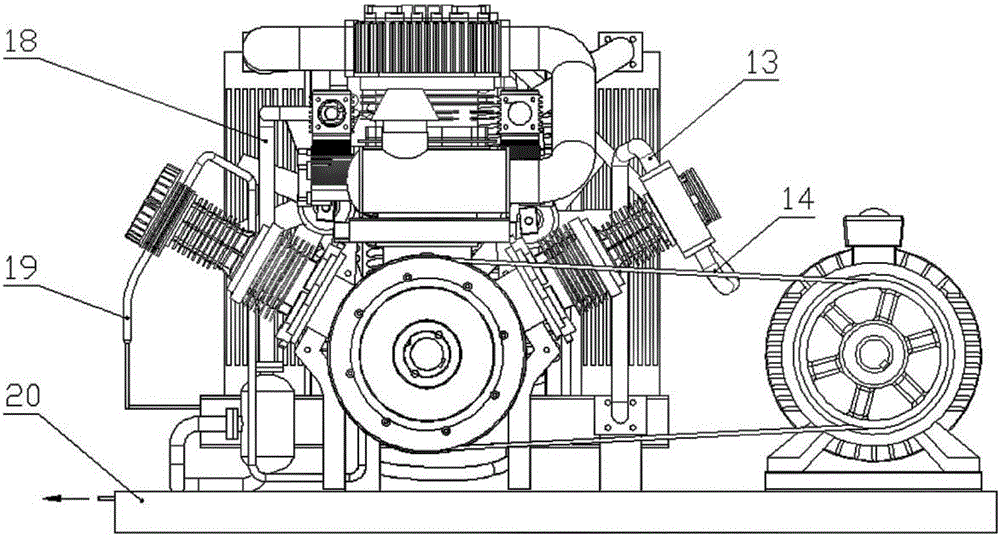

[0045] Such as figure 1 , Figure 3-Figure 7 Shown is a schematic structural view of a preferred embodiment of the four-stage W-type high-pressure compressor according to the present invention. A four-stage W-type high-pressure compressor of the present invention includes a compression system, a drive system, a power supply control system, a condensed water oil separation system and a cooling system, and is characterized in that the compressor adopts a four-stage three-cylinder design, and The air cylinder and the second-stage cylinder are concentrated in one connected piston cylinder, which simplifies the mechanical structure and reduces the number of moving rods, thus s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com