Efficient power generation system based on liquefied natural gas and working method of efficient power generation system

A technology for liquefied natural gas and power generation systems, which is applied to machines/engines, steam engine installations, mechanical equipment, etc., can solve the problems of compressor stability control, system regulation difficulties, blade water erosion, etc., to reduce the difficulty of sealing technology and improve cycle efficiency. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with the accompanying drawings and examples, and its content is to explain rather than limit the present invention:

[0028] Liquid natural gas contains cold energy, which cannot be used well at present; the current cycle efficiency of supercritical carbon dioxide is not high, and the system is complicated. The high-efficiency power generation system based on liquid natural gas of the present invention combines the power cycle of carbon dioxide and the cold energy utilization of liquid natural gas, and solves the current technical problems.

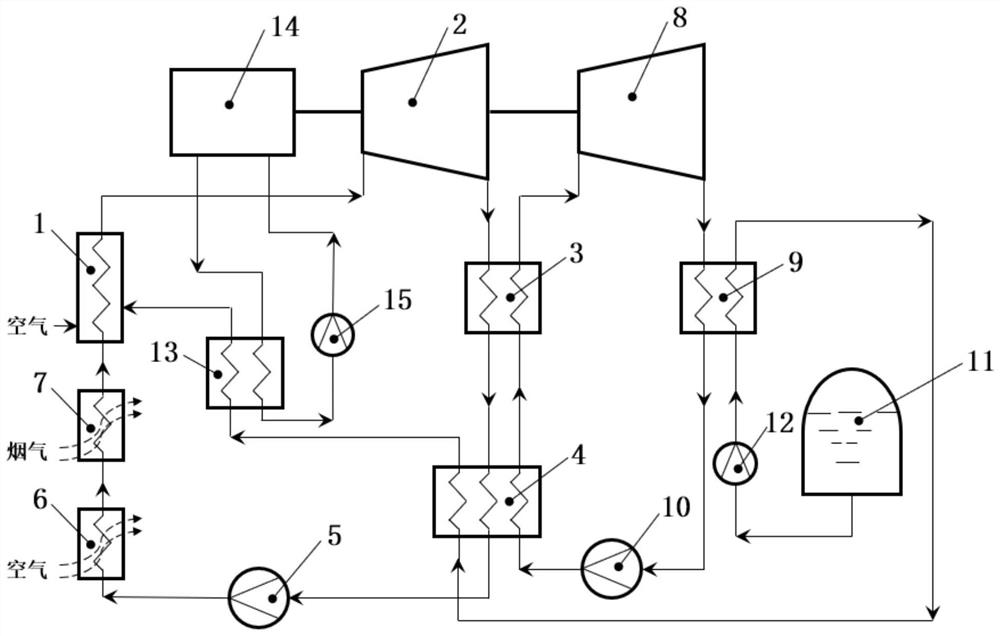

[0029] like figure 1, is the high-efficiency power generation system based on liquid natural gas of the present invention, including a natural gas boiler 1, a carbon dioxide gas turbine 2, a first-stage carbon dioxide heat exchanger 3, a second-stage carbon dioxide heat exchanger 4, a carbon dioxide pump 5, an air heat exchanger 6, a smoke Gas heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com