Image processing-based rail profile detecting device and method

An image processing and detection device technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as affecting driving safety, increasing grinding workload, and deteriorating rail quality, so as to improve measurement accuracy, improve accuracy, reduce The effect of small cumulative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

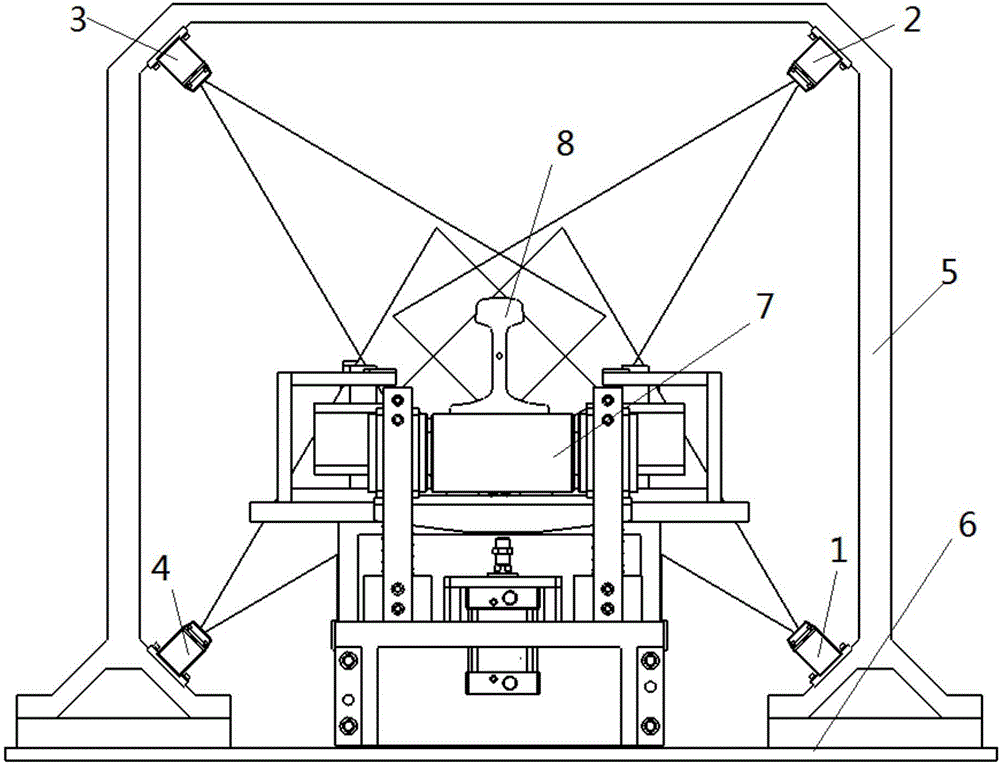

[0046] The invention provides a rail profile detection device and method based on image processing, utilizing figure 1 The device shown is realized. The device uses the triangular ranging principle of the laser sensor to collect profile data. After calibration, the profile size data of the rail 8 section is obtained, and the data is used to measure the profile parameters of the rail.

[0047] The device includes four sensors, a sensor bracket 5, a base 6, a track conveying roller 7 and a rail 8, wherein: the four sensors are laser profile sensors, which are respectively the first sensor 1, the second sensor 2, the third sensor 3, the Four sensors 4, all adopt the same type of linear laser ranging sensor (such as Gocator2350 sensor), they are respectively installed at the four inner corners of the sensor bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com