On-satellite high-precision cross-calibration system

A high-precision, calibration technology, applied in the field of aerospace optical remote sensors, can solve the problems of inability to perform spectral calibration, the built-in calibration plate and detector decay cannot be corrected, and the calibration capability of remote sensors cannot be achieved, and achieve high precision. Radiation calibration and wavelength calibration capability, the effect of having radiation calibration and wavelength calibration capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

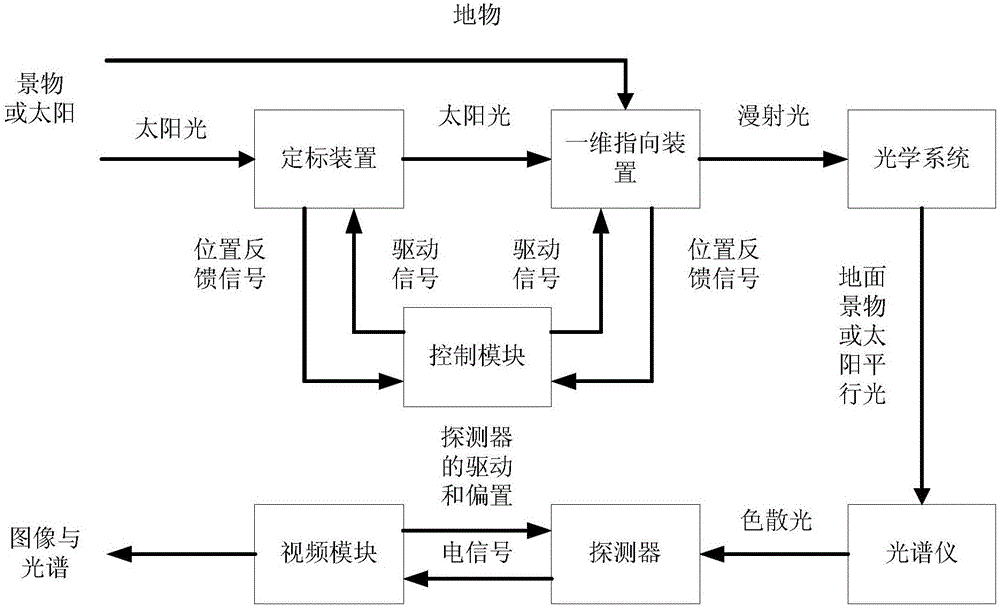

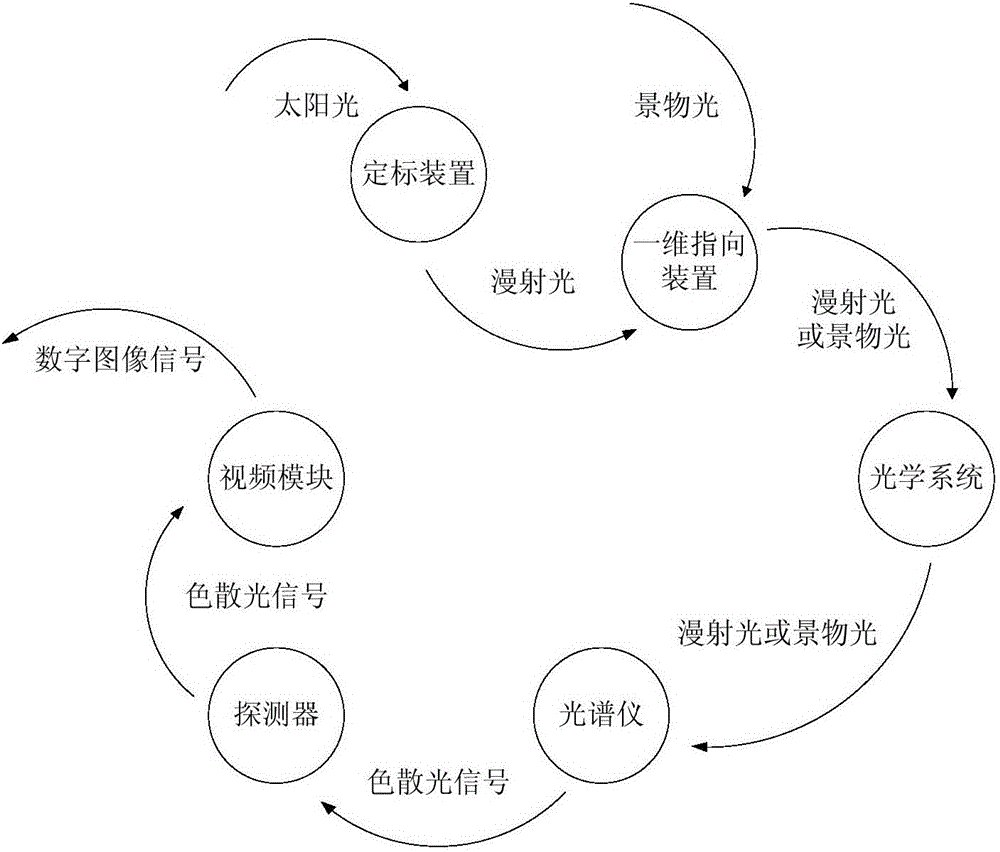

[0020] The present invention will be described in detail below in conjunction with the drawings, such as figure 1 , figure 2 As shown, an on-board high-precision cross calibration system includes: a one-dimensional pointing device, a calibration device, a control module, an optical system, a spectrometer, a detector, and a video module;

[0021] The one-dimensional pointing device is mainly composed of a motor, an optical element, an angle measuring element and a structure. The motor uses a three-phase permanent magnet torque motor. The angle measuring element adopts a resolver, and the resolver sends angle information to the control module. The motor in the one-dimensional pointing device receives the control signal sent by the control module to realize rotation. The optical element is installed on the motor shaft, and the rotation of the motor can drive the optical element to follow. So as to realize the switching of different incident scenes. The structure of the one-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com