A device and method for temperature measurement of face turning

The technology of a measuring device and measuring method, which is applied in the direction of measuring device, temperature measurement of moving solids, and electric devices, etc., can solve the problems of inaccurate measurement results, easy mutual interference of devices, complex structure, etc., and achieve convenience in the experimental process, eliminate Interference problem, effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

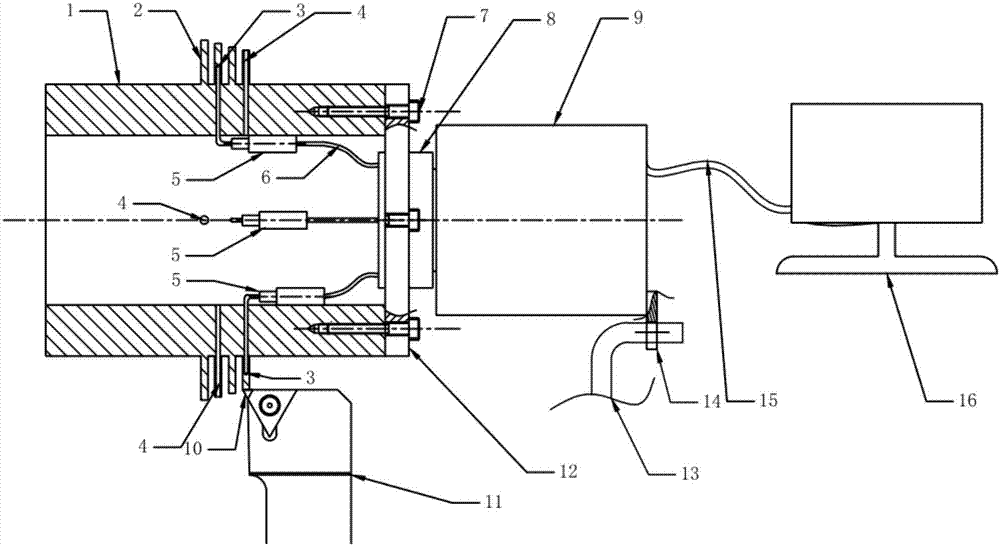

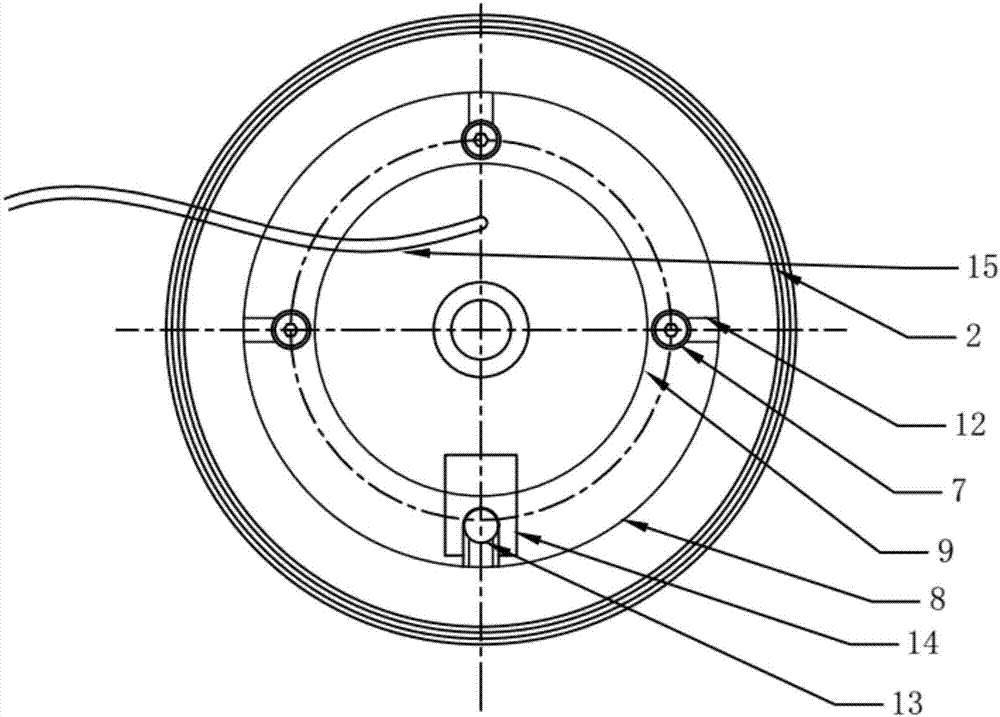

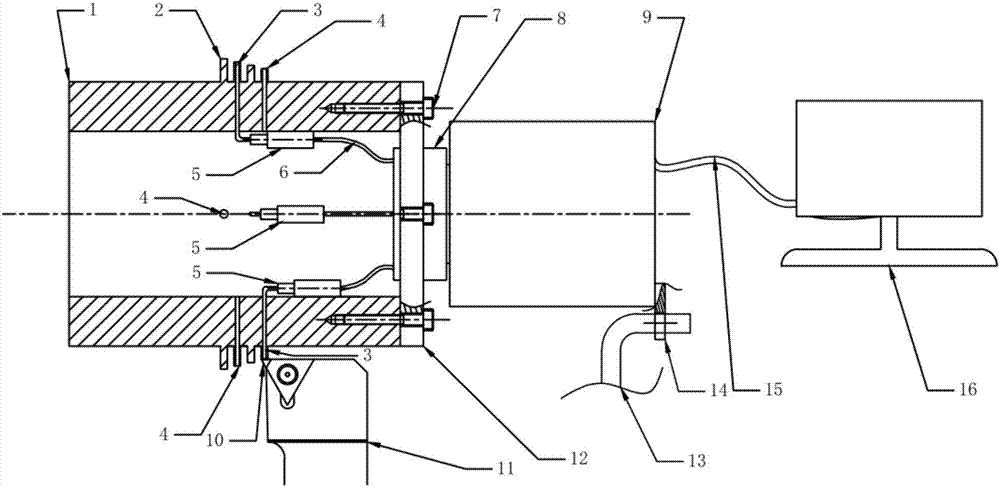

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0019] like figure 1 As shown, the device includes a thermocouple sensor 5, a slip ring 9, a temperature signal processing terminal 16 and an experimental workpiece 1; the experimental workpiece 1 is a product of a turning temperature material to be measured, which is cylindrical, and a clamping space is reserved on the left side. The width of the turning tool is reserved on the right side, and the protruding annular rib 2 is in the middle. The number of annular ribs 2 on the experimental workpiece 1 is more than two, the height of the annular ribs 2 is 5-15mm, and the height gradually decreases from left to right; the thickness of the annular ribs 2 does not exceed the width of the blade 10, so that This outer circle turning process is equivalent to a 90° turning tool face turning process; the groove in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com