Grinding-disk crushing experiment facility and method suitable for in-pipe hydrate particles

An experimental device and hydrate technology, applied to the analysis of materials, instruments, etc., to achieve the effect of solving the problem of primary separation and fluidized pipeline transportation, compact structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

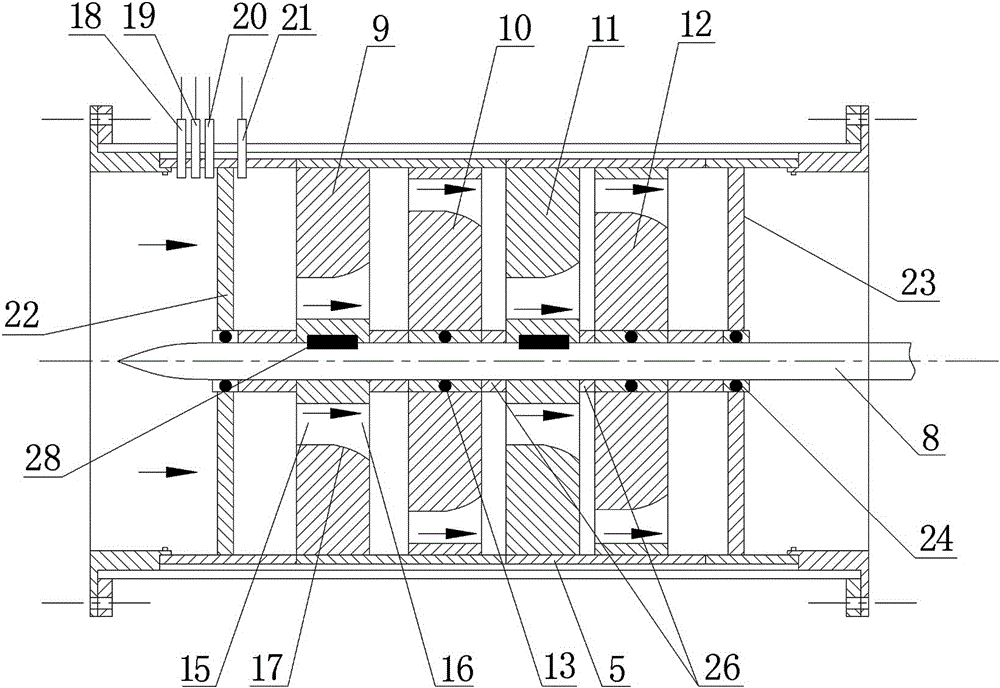

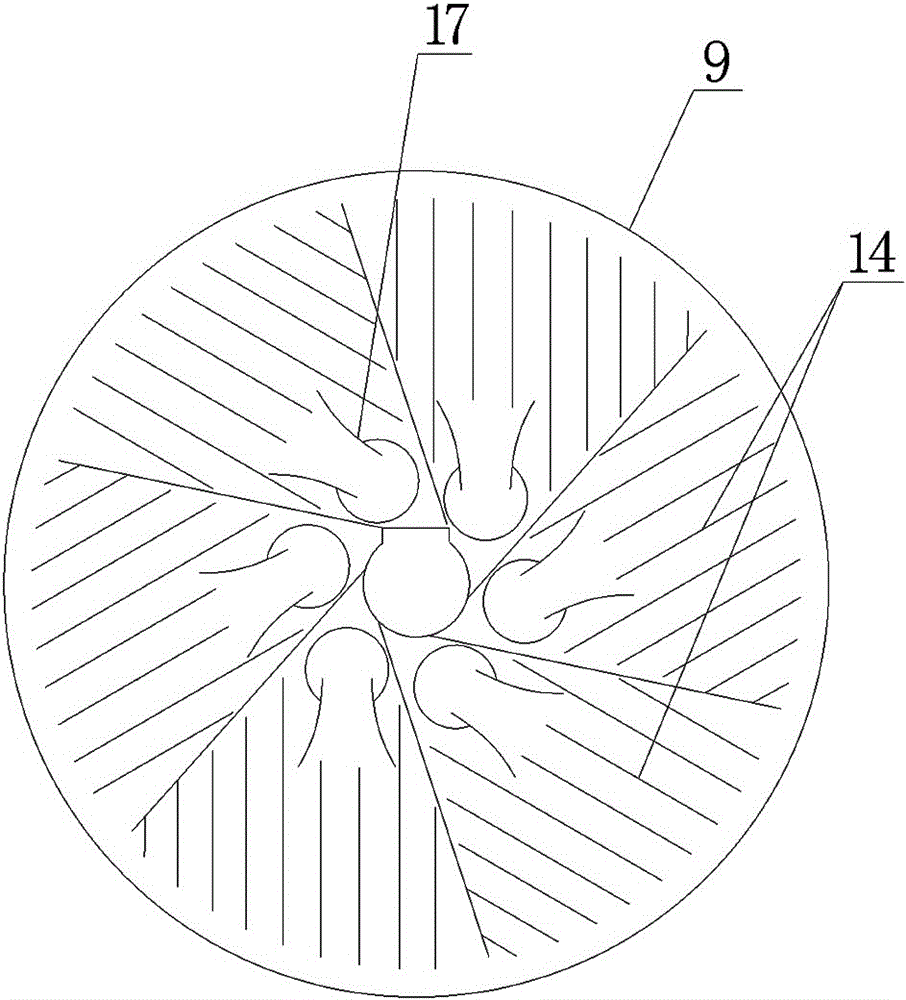

[0030] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

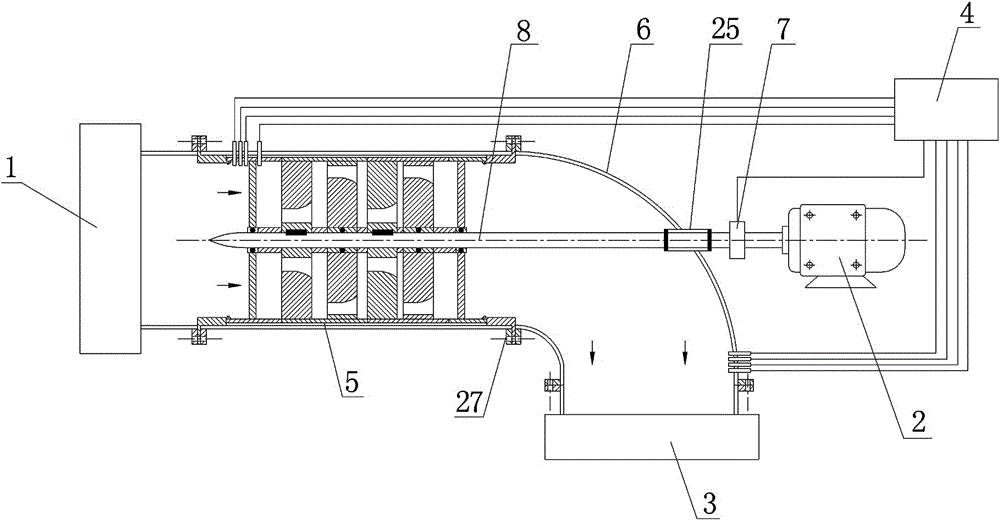

[0031] Such as Figure 1~4 As shown, a disc-type crushing experimental device suitable for hydrate particles in the pipe includes a material pre-mixing device 1, a crushing pipeline section, a crushing disc unit, a power unit 2, a receiving device 3 and a monitoring and control system 4.

[0032] The crushing pipe section is composed of a crushing pipe 5 connected end to end and an outlet elbow 6. The crushing pipe 5 and the outlet elbow 6 are connected through a flange 27. The other end of the crushing pipe 5 is connected to the material premixing device 1. The mixing device 1 is a screw mortar pump, and the other end of the outlet elbow 6 is connected to the receiving device 3, and the receiving device 3 is used to collect the crushed extremely small particle hydrate.

[0033] The output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com