Comprehensive test bench and test method for air filter or filter material

An air filter and filter material technology, which is applied in the field of air purification, can solve the problems of short purification time, rough filtering effect detection method, and uncertainty, and achieve the effect of short purification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

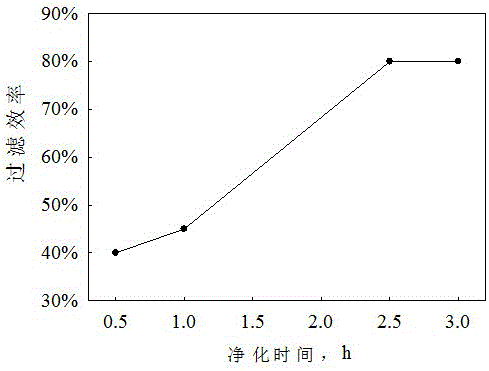

[0024] Example 1: Test the filtering performance of a certain brand of filter.

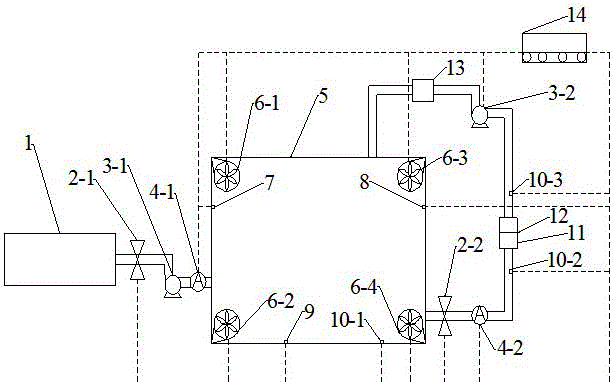

[0025] Such as figure 1 As shown, this air filter or filter material comprehensive test bench and test method are composed of four systems: aerosol generation system, mixing system, test system and automatic control system. The aerosol generation system consists of an aerosol generator 1, a first electric butterfly valve 2-1, a first electromagnetic flowmeter 4-1, and a first micro vacuum pump 3-1; the mixing system consists of a test box 5 and a first low-pressure fan 6 -1, second low-pressure fan 6-2, third low-pressure fan 6-3, fourth low-pressure fan 6-4, humidifier 7, surface cooler 8, temperature and humidity sensor 9, first aerosol detector 10-1 Composition; The test system includes the second electric butterfly valve 2-2, the second electromagnetic flowmeter 4-2, the fixture 11, the slide 12, the second micro vacuum pump 3-2, the high efficiency filter 13; the automatic control system is main...

Embodiment 2

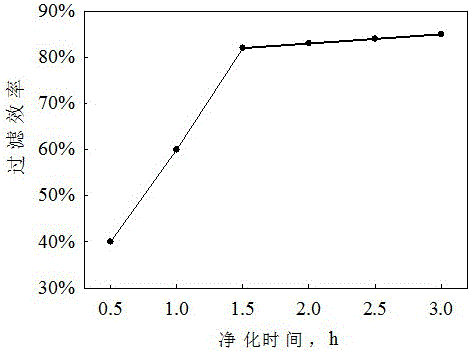

[0027] Example 2: Test the filtration performance of a certain brand of filter material

[0028] Such as figure 1 As shown, this air filter or filter material comprehensive test bench and test method are composed of four systems: aerosol generation system, mixing system, test system and automatic control system. The aerosol generating system is composed of an aerosol generator 1, a first electric butterfly valve 2-1, a first electromagnetic flow meter 3-1, and a first micro vacuum pump 4-1; the mixing system is composed of a test box 5 and a first low-pressure fan 6 -1, second low-pressure fan 6-2, third low-pressure fan 6-3, fourth low-pressure fan 6-4, humidifier 7, surface cooler 8, temperature and humidity sensor 9, first aerosol detector 10-1 Composition; The test system includes the second electric butterfly valve 2-2, the second electromagnetic flowmeter 3-2, the fixture 11, the slide 12, the second micro vacuum pump 3-2, and the high-efficiency filter 13; the automatic co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com