Purification method for treating araban in alkali treatment water for orange and tangerine tin can processing

A technology for arabinan and a purification method, which is applied to the field of purifying arabinan from canned citrus processing alkali-treated water, can solve the problems of unsuitability for large-scale production, low yield per unit time, complicated steps and the like, and achieves short purification time and cheap source. , the effect of simple purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

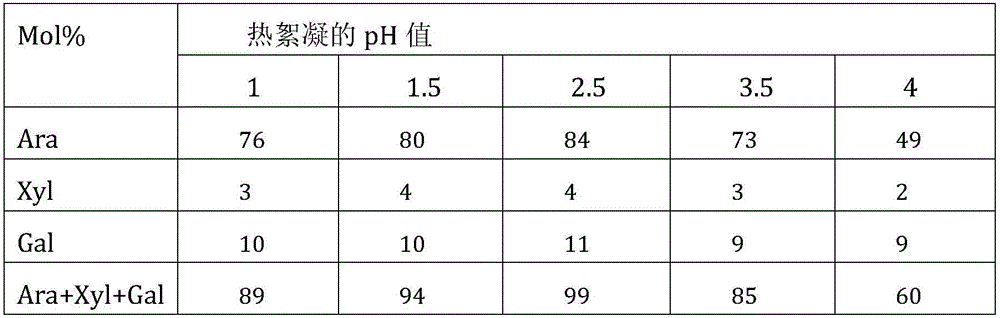

[0035] In this example, concentrates with different pH are used for heating and flocculation to optimize the purification effect of arabinan. The specific steps are as follows:

[0036] Take the alkali-treated water from the canned citrus processing and decapsulation process, and use HCl solution to adjust the pH to 5-7 (the concentration of HCl solution is not quantitative, and using a larger concentration can improve the efficiency of pH adjustment, and a large concentration of HCl requires a large stirring rate). Then use a vacuum concentrator to concentrate under reduced pressure at 50°C, and detect the total solid content (mass fraction) online, stop concentrating when the total solid mass fraction is 1.7-1.8%, and pump the concentrated solution into the acid-resistant heating Device, use 3mol / L hydrochloric acid solution to adjust the pH to 1, 1.5, 2.5, 3.5, 4. Evenly heated at 92°C for 15 minutes to produce flocs. After cooling down slightly, use a 350-mesh filter cloth...

Embodiment 2

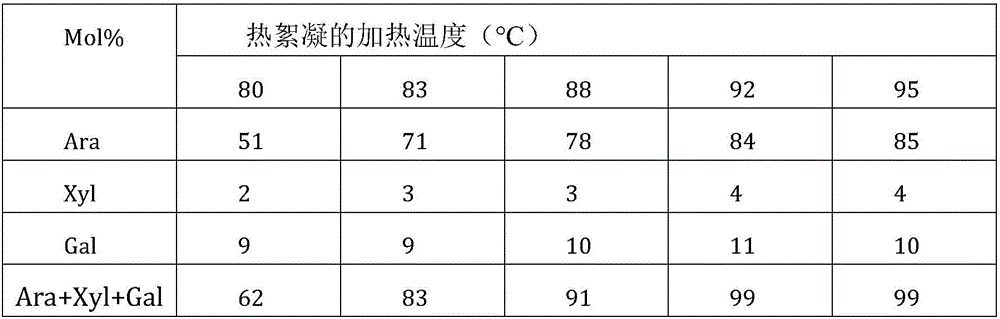

[0040] In this embodiment, different heating temperatures are used to optimize the purification effect of arabinan. The specific steps are as follows:

[0041]Take the alkali-treated water from the canned citrus processing and decapsulation process, and use HCl solution to adjust the pH to 5-7 (the concentration of HCl solution is not quantitative, and using a larger concentration can improve the efficiency of pH adjustment, and a large concentration of HCl requires a large stirring rate). Then use a vacuum concentrator to concentrate under reduced pressure at 50°C, and detect the total solid content (mass fraction) online, stop concentrating when the total solid mass fraction is 1.6-1.7%, and pump the concentrated solution into the acid-resistant heating device, use 3mol / L hydrochloric acid solution to adjust the pH to 2.5. Heat uniformly at 80, 83, 88, 92, and 95°C for 15 minutes to produce flocs. After a little cooling, use a 350-mesh filter cloth to filter and collect the ...

Embodiment 3

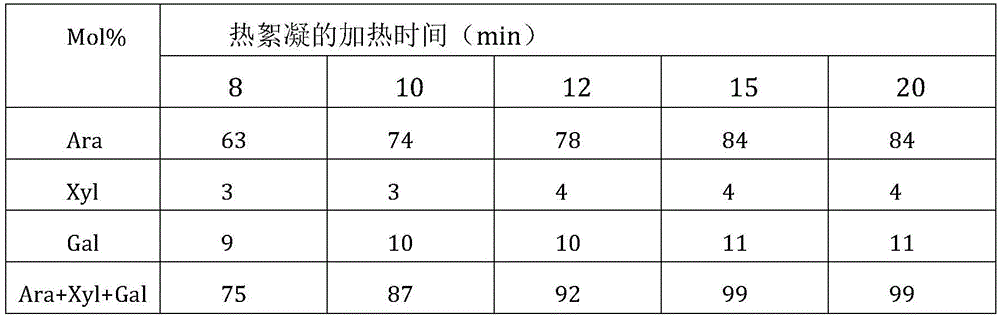

[0045] In this embodiment, different heating times are used to optimize the purification effect of arabinan. The specific steps are as follows:

[0046] Take the alkali-treated water from the canned citrus processing and decapsulation process, and use HCl solution to adjust the pH to 5-7 (the concentration of HCl solution is not quantitative, and using a larger concentration can improve the efficiency of pH adjustment, and a large concentration of HCl requires a large stirring rate). Then use a vacuum concentrator to concentrate under reduced pressure at 50°C, and detect the total solid content (mass fraction) online, stop concentrating when the total solid mass fraction is 1.5-1.6%, and pump the concentrated solution into the acid-resistant heating device, use 3mol / L hydrochloric acid solution to adjust the pH to 2.5. Heating evenly at 92°C for 8min, 10min, 12min, 15min, and 20min respectively to produce flocs, after cooling slightly, filter with a 350-mesh filter cloth, coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com