U-shaped plastic optical fiber liquid refractive index sensor with multi-groove structure

A technology of liquid refractive index and plastic optical fiber, which is applied in the direction of instruments, scientific instruments, and analytical materials, can solve the problems of expensive photonic crystal optical fiber, complex process, and increased testing cost, and achieve commercial production, simple manufacturing process, and Easy installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto, and equivalent replacements that are substantially the same as the present invention all belong to the protection scope of the present invention. Embodiment 1: Taking the measurement of aqueous glycerin as an example

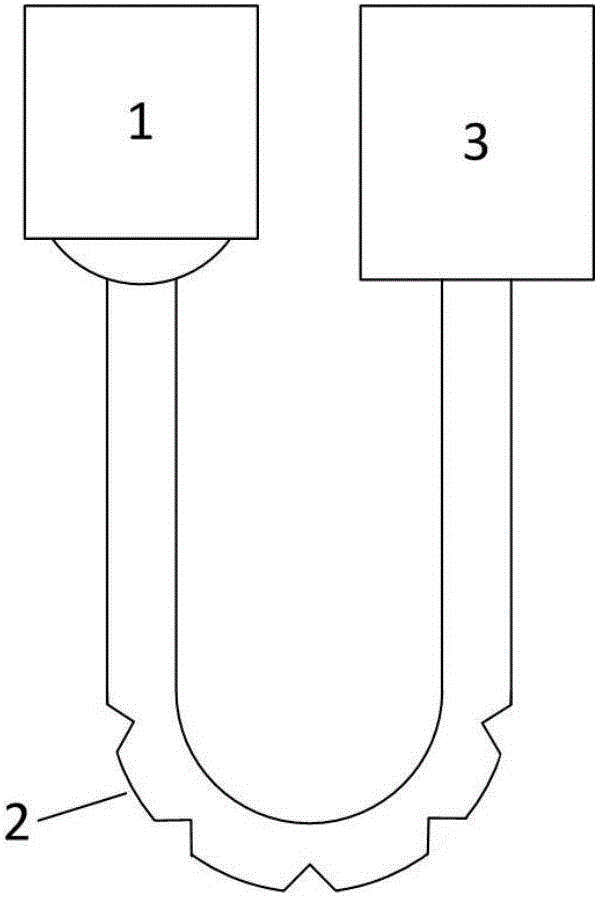

[0029] see figure 1 , the U-shaped plastic optical fiber refractive index sensor with multi-slot structure of the present invention is composed of a light source 1, a plastic optical fiber sensing probe 2 with a multi-slot structure and an optical power meter 3. Since the fabricated fiber optic probe has a symmetrical structure, the light source can be connected to any end of the fiber optic probe through an optical fiber, and the other end of the fiber optic probe is connected to an optical power meter through an optical f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com