Determination method of mechanical denudation rate of carbon/carbon composite material

A carbon composite material and a technology to determine the method, applied in the field of material heat resistance analysis, can solve the problems of difficult prediction of ablation performance and insufficient universality of prediction of ablation performance difference, etc. Describe the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Further illustrate the present invention below in conjunction with accompanying drawing.

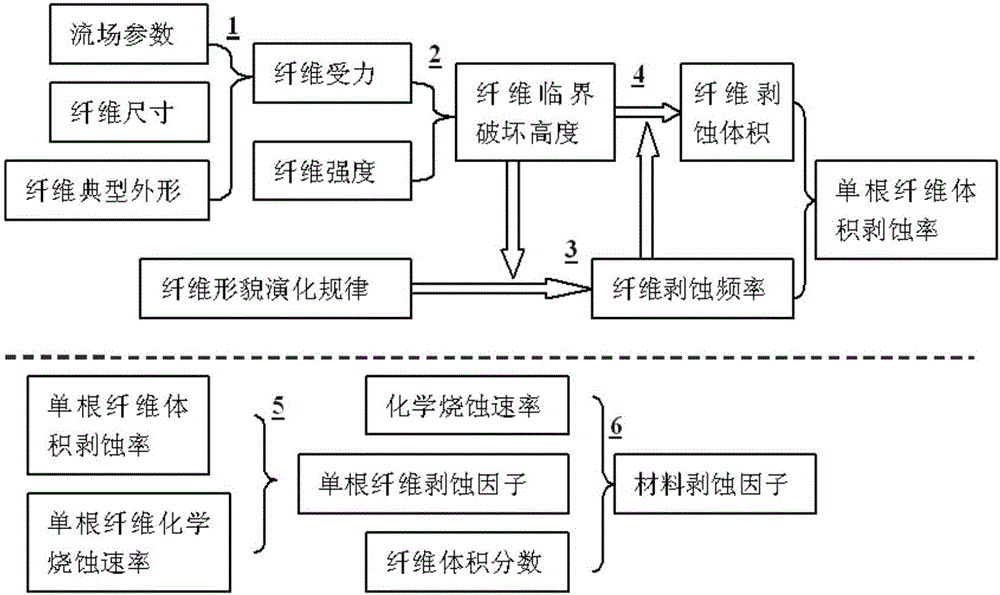

[0041] Such as figure 1 Shown basic flowchart of the inventive method, the concrete implementation process of the present invention is as follows:

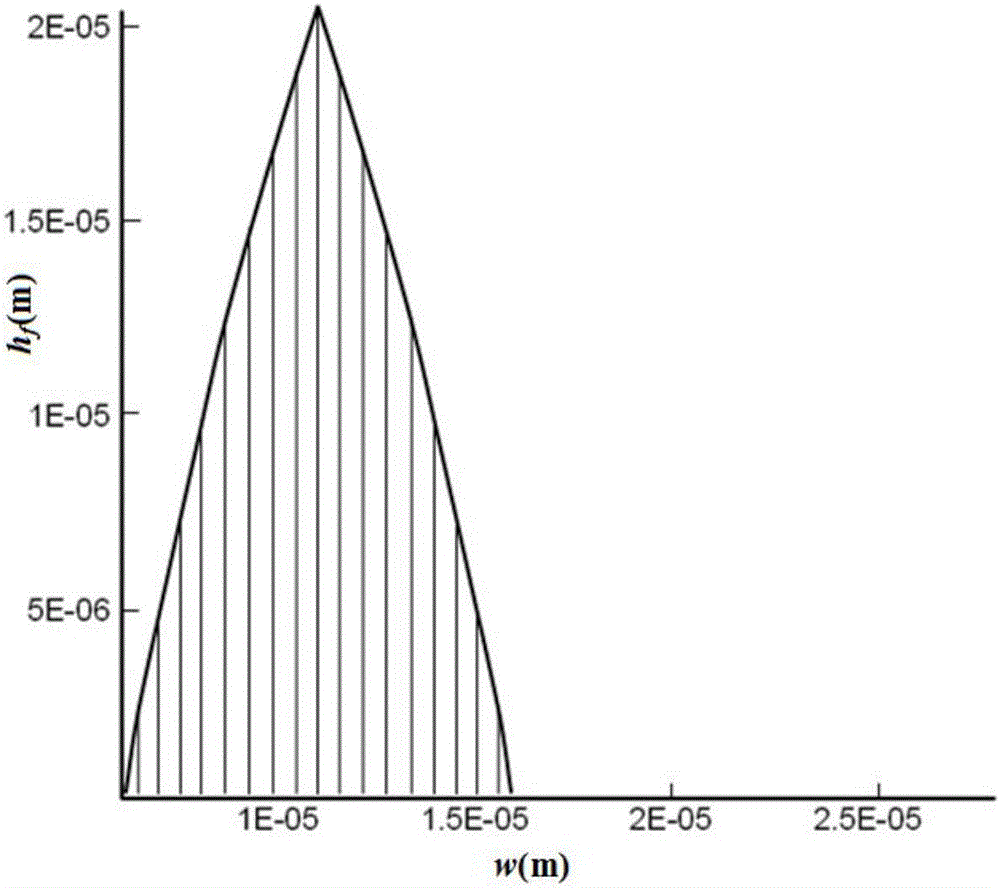

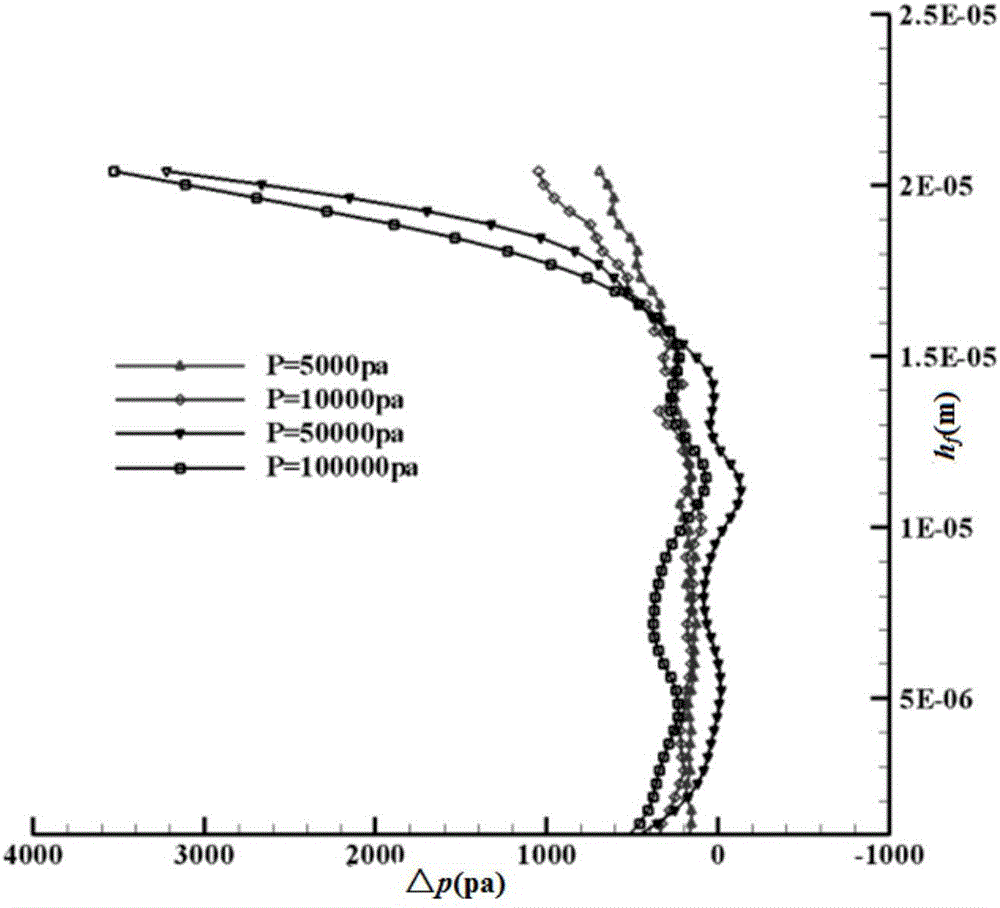

[0042] 1. Using fiber to ablate the typical shape ( figure 2 ) combined with the flow field analysis, the surface pressure difference △p on both sides of the fiber is obtained as the fiber exposure height h f The law of change ( image 3 ). The pressure level below 80% of the lower part of the fiber is small and negligible. The surface pressure difference within the upper 20% of the fiber is simplified as a concentrated force. The action point is located at 90% of the fiber height, and the magnitude is determined by integrating the pressure difference along the fiber shape. According to the analysis results of the concentration force under different flow pressure conditions, it can be seen that the concentration force on the fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com