Clamped beam T-shaped junction direct heating on-line known frequency microwave phase detector

A technology of phase detector and clamped beam, which is applied in thermal method for electric power measurement, phase angle between voltage and current, instruments, etc. It can solve the problems of low power consumption, consumption of detection signals, etc. consumption, high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

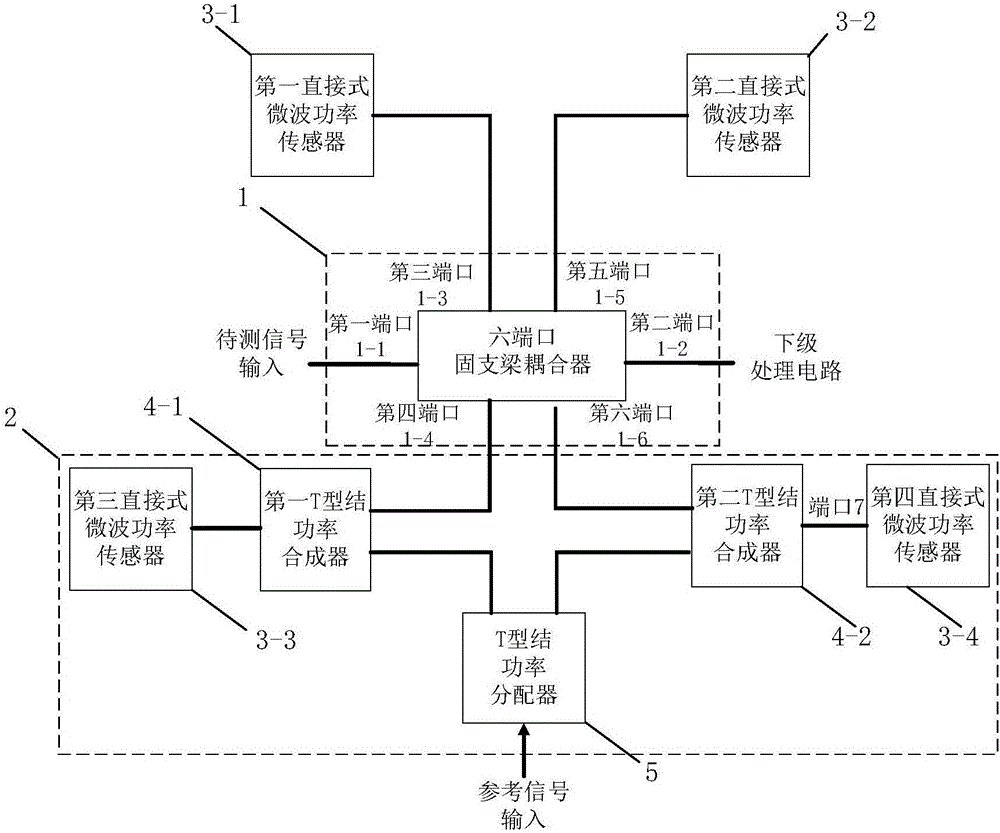

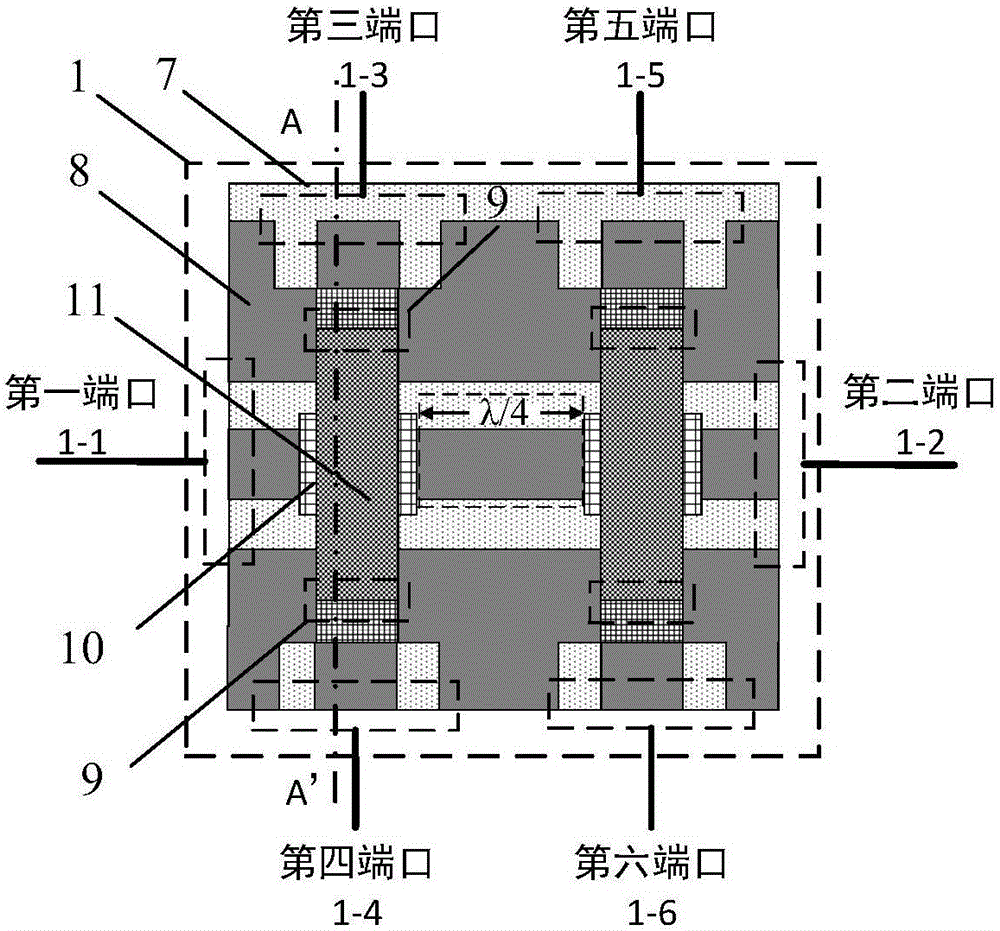

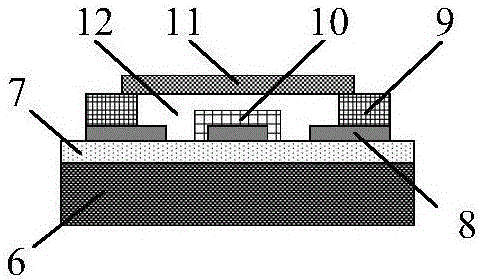

[0020] The fixed-supported beam T-junction indirect heating on-line known frequency microwave phase detector of the present invention consists of a six-port fixed-supported beam coupler 1, a microwave phase detector 2, a first indirect heating microwave power sensor 3-1 and a second Indirect heating microwave power sensor 3-2 cascade structure;

[0021] The first port 1-1 to the third port 1-3, the fourth port 1-4, the first port 1-1 to the fifth port 1-5, and the sixth port 1-6 of the six-port fixed beam coupler 1 The power coupling degrees are the same. The signal to be tested is input through the first port 1-1 of the six-port fixed beam coupler 1, and is output to the first indirect heating type by the third port 1-3 and the fifth port 1-5 respectively. The microwave power sensor 3-1 and the second indirect heating microwave power sensor 3-2 are output to the microwave phase detector 2 by the fourth port 1-4 and the sixth port 1-6, and output to the microwave phase detecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com