On-line Microwave Phase Detector with Unknown Frequency Directly Heated by Fixed Beam

A technology of phase detectors and fixed beams, which is applied in frequency measurement devices, electric power measurement by thermal method, manufacturing measuring instruments, etc., can solve the problems of low power consumption and consumption of detection signals, and achieve no DC power consumption, high The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

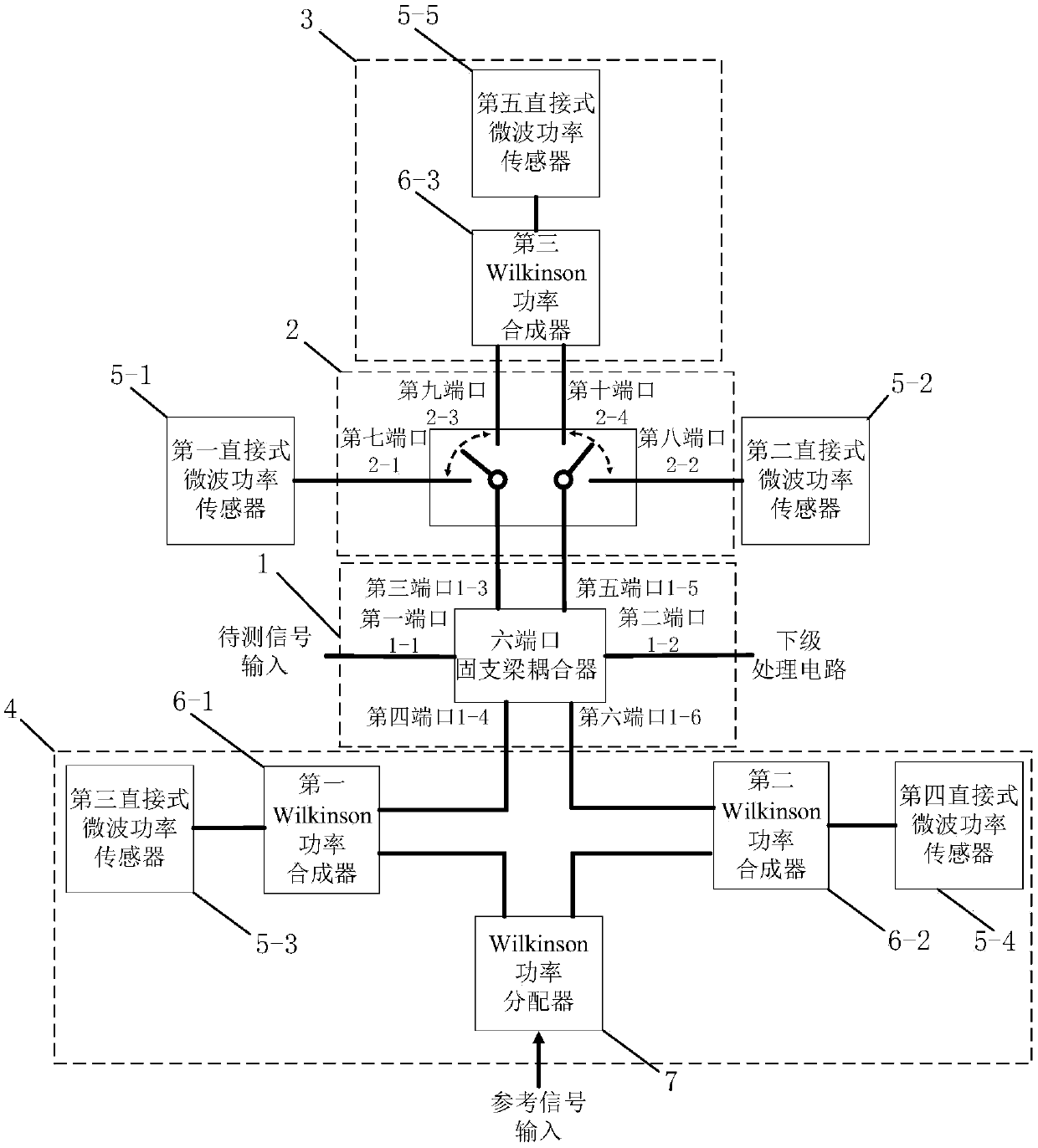

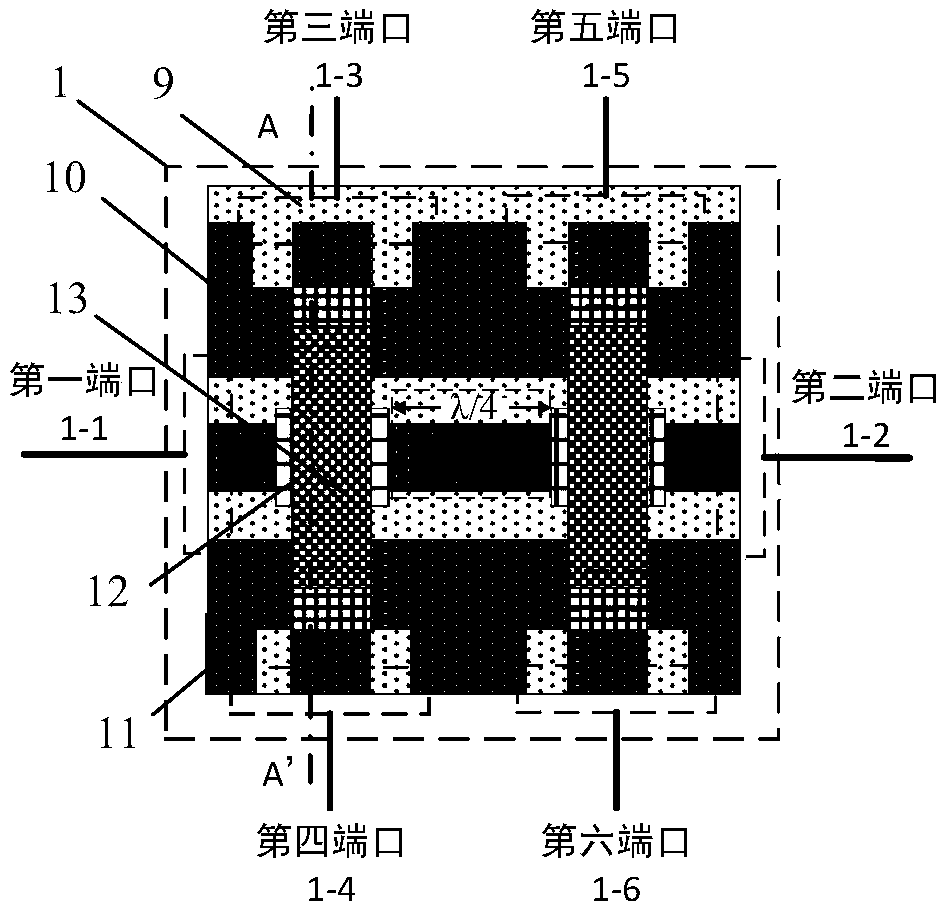

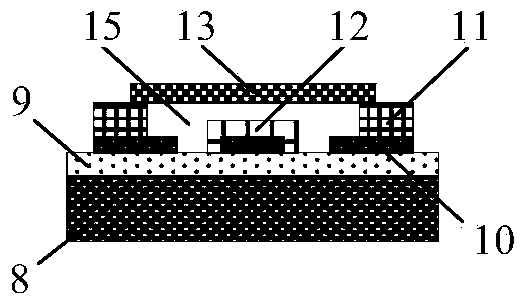

[0019] The solid-supported beam direct heating online unknown frequency microwave phase detector of the present invention consists of a six-port fixed-supported beam coupler 1, a channel selection switch 2, a microwave frequency detector 3, a microwave phase detector 4, and 5 stages of direct heating microwave power sensors The six-port fixed beam coupler 1 is composed of a coplanar waveguide 10, a dielectric layer 12, an air layer 15 and a fixed beam 13 across it; the coplanar waveguide 10 is made of SiO 2 On the layer 9, the anchor region 11 of the fixed beam 13 is made on the coplanar waveguide 10, and the dielectric layer 12 is deposited under the fixed beam 13, and forms a coupling capacitor structure together with the air layer 15 and the fixed beam 13, two The length of the coplanar waveguide 10 between the fixed support beams 13 is λ / 4; the channel selection switch 2 is composed of the coplanar waveguide 10, the anchor region 11, the dielectric layer 12, the cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com