UG-based optimization method of planar-cavity small-curvature radius arc numerical control processing

An optimization method and small curvature technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of increasing the total processing time of parts, increasing the total time of finishing machining, and reducing productivity, so as to shorten processing time and reduce precision. Processing time, the effect of reducing the total time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

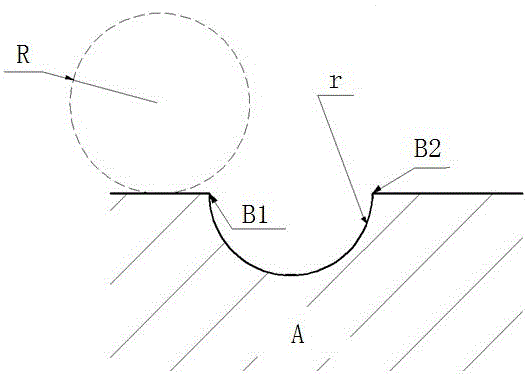

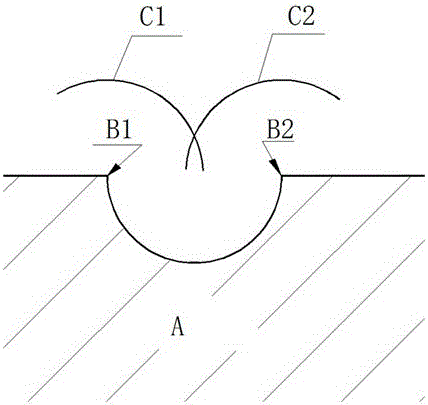

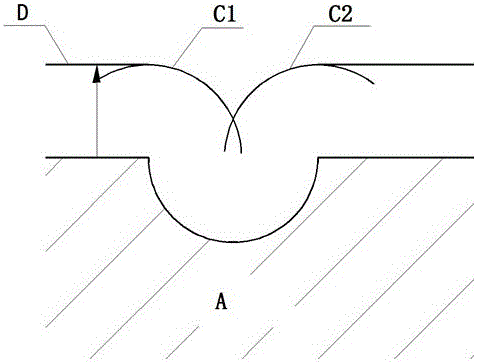

[0018] refer to Figure 1 to Figure 4 and Figure 6 , the optimization method based on the UG planar cavity small curvature radius arc numerical control machining provided by the present invention, the method includes:

[0019] (1) Find out the arc start point B1 and the arc end point B2 where r

[0020] (2) Make arcs C1 and C2 with the arc starting point B1 and the arc end point B2 as the center and R as the radius respectively;

[0021] (3) The remaining curves of the contour of the workpiece A are compensated for displacement with the radius R of the tool;

[0022] (4) The curve obtained by intersecting the two arcs C1 and C2 with the displacement compensation curve D is the optimized tool center trajectory E1.

[0023] Then, check whether the motion track of the machining tool has been searched. If not, return to the first step, repeat the above steps until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com