A method for improving the processing efficiency of titanium alloy cavity fillet

A processing efficiency, titanium alloy technology, applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of many types of tool specifications, inconsistent processing quality, serious tool gap, etc., to achieve consistent and stable processing quality and program capacity Small size, tool cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

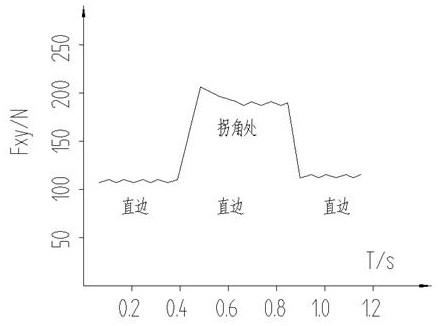

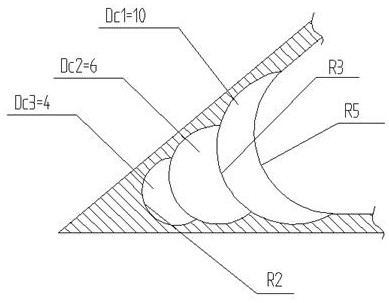

[0024] see image 3 , the processing method of the groove fillet R2:

[0025] Step 1. Milling the bottom of the cavity to form a fillet with a radius of 2, which is carried out in three steps,

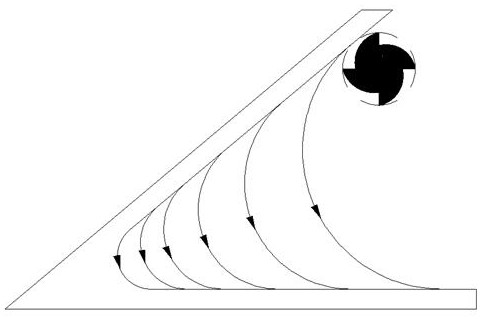

[0026] The first step: the rough machining of the fillet of the cavity, the diameter Dc is selected 1 =10 rough machining milling cutter, keep the rough machining milling cutter to make feed motion along the axial direction, use the cutting edge at the bottom of the rough machining milling cutter to perform combined drilling and milling cutting on the bottom of the groove cavity, rough milling with large allowance, groove Rough machining of cavity fillet A R5 fillet is processed at the bottom of the cavity;

[0027] The second step: semi-finishing the fillet of the cavity, the diameter Dc is selected 2 =6 semi-finishing milling cutter, keep the semi-finishing milling cutter to do feed motion along the axial direction, utilize the cutting edge at the bottom of the semi-finishing cutt...

Embodiment 2

[0033] Processing method of groove fillet R4:

[0034] Step 1. Mill the bottom of the cavity to form a fillet with a radius of 4. Select a cutting milling cutter with a diameter of Dc=8. During milling, keep the cutting milling cutter moving in the axial direction, and use the bottom of the cutting milling cutter to The cutting edge performs drilling and milling combined cutting on the bottom of the groove cavity. When the cutting milling cutter is milling, the milling parameters are 2000 rpm, the cutting width is 1 / 3~1 / 2 of the diameter of the cutting milling cutter, and the feed rate is 0.08~0.25min / tooth, the cutting milling cutter is a titanium alloy cemented carbide milling cutter, and the cutting edge angle of the cutting milling cutter is 87° or 90°.

[0035] Step 2: Use layered milling to process the groove allowance outside the fillet. For the residue after milling in step 1, use an end mill to remove it to form a straight edge of the groove.

[0036] The processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com