Multi-target fast optimum design method of pumping and spraying propeller

A technology for optimizing design and thrusters, applied in design optimization/simulation, instrumentation, calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

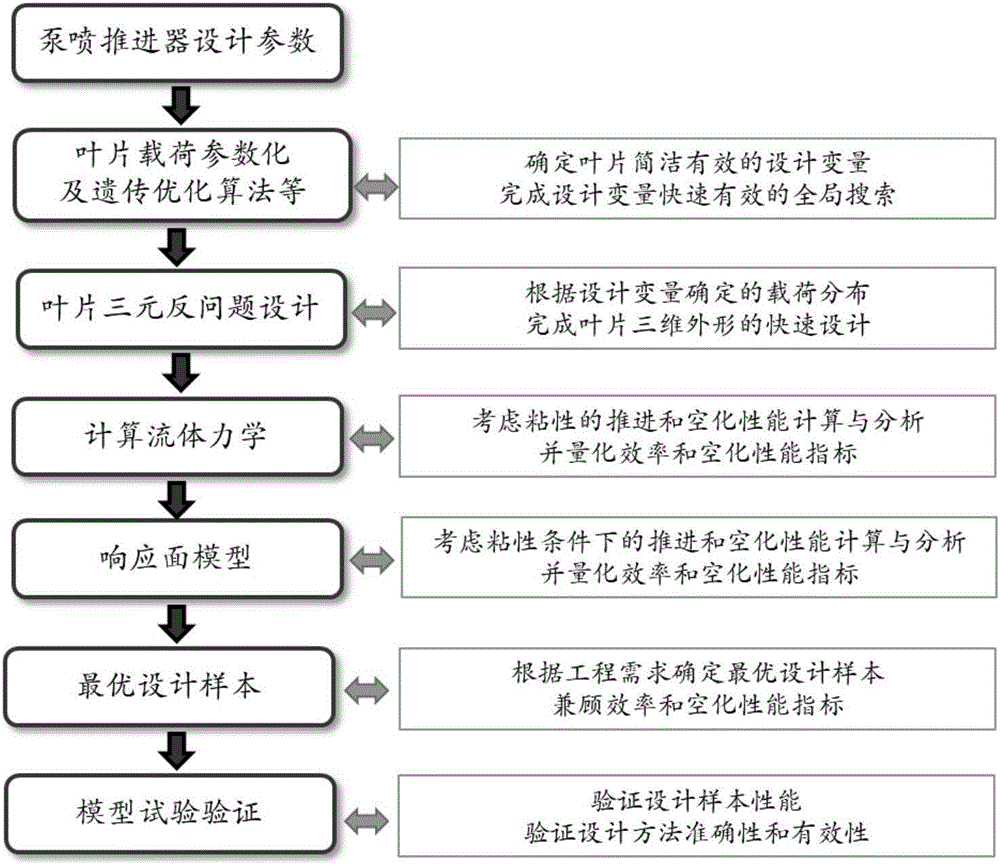

[0019] Such as figure 1 As shown, the present invention provides a multi-objective rapid optimization design method for a pump-jet propeller, which is characterized in that it comprises the following steps:

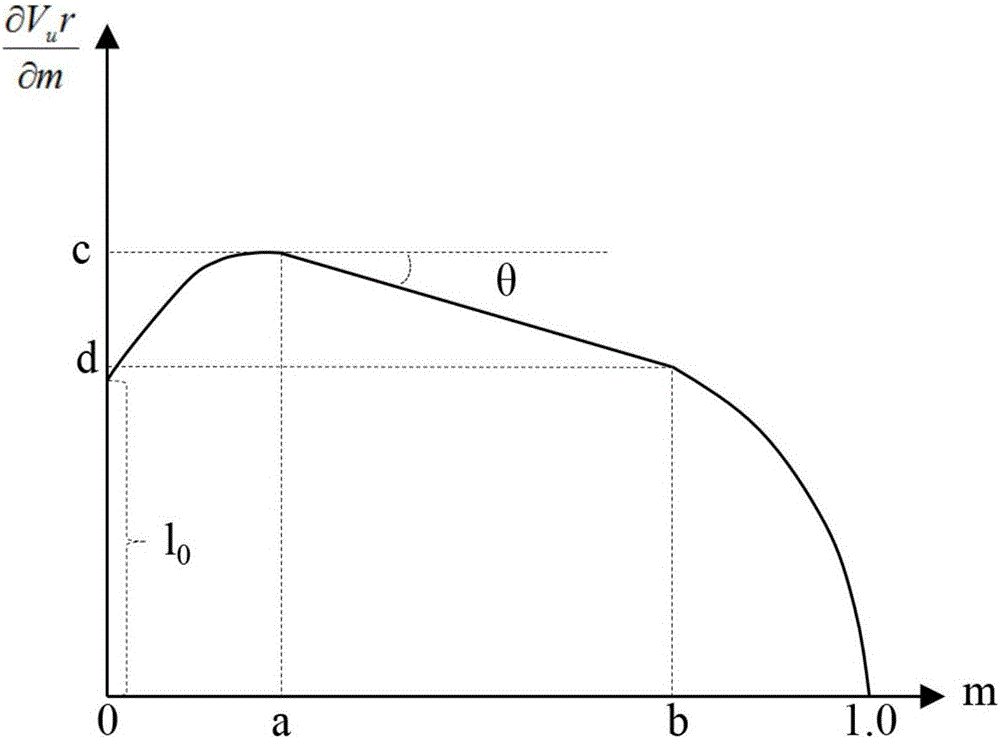

[0020] 1) According to the lift, rotational speed, inlet and outlet dimensions and the definition of the lift of the target pump waterjet, determine the value of the impeller blade inlet and outlet loads. Usually in colloquial terms, we use the blade load to indicate the strength of the blade's work. In fact, the load distribution is the blade circulation distribution in academic terms. The difference between the inlet and outlet of the pump propeller determines the lift of the propeller, and the height of the lift determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com