Electrical equipment inspection method and system based on RFID technology

A technology of electric power equipment and inspection system, which is applied in the direction of inspection time patrol, cooperative operation devices, instruments, etc., can solve the problems of difficult to effectively supervise the inspection process, insufficient inspection, interference, etc., to improve the inspection work High efficiency, fast recognition speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of specific steps of the power equipment inspection method based on RFID technology are:

[0035] The first step is to build a power equipment inspection system based on RFID technology

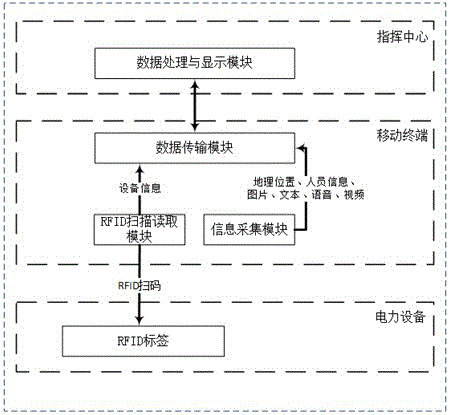

[0036] The power equipment inspection system based on RFID technology includes: RFID tag association module, RFID scanning and reading module, information collection module, data transmission module and data processing and display module. Said:

[0037] The function of the RFID tag association module is: associate the RFID tag with the corresponding electric equipment;

[0038] The functions of the RFID scanning and reading module are: patrol scanning and reading RFID tag data;

[0039] The functions of the information collection module are: collecting personnel, location and image information;

[0040] The function of the data transmission module is: to transmit inspection data and receive instruction data;

[0041] The function of the data processing and display module is ...

Embodiment 2

[0054]A power equipment inspection system based on RFID technology includes: RFID tags, RFID scanning and reading modules, information collection modules, data transmission modules, and data processing and display modules.

[0055] Among them, the function of the RFID scanning and reading module is: inspection scanning to read RFID tag data; the function of the information collection module is: collecting personnel, location and image information; the function of the data transmission module is: transmitting inspection data and receiving instruction data; The functions of the data processing and display module are: correlating and displaying the inspection data;

[0056] Among them, there are multiple RFID tags and are matched with the RFID scanning and reading module. The data information obtained by the RFID scanning and reading module and the information acquisition module are all transmitted to the data processing and display module through the data transmission module. In...

Embodiment 3

[0058] A mobile terminal, including an RFID scanning and reading module, an information collection module and a data transmission module, wherein the RFID scanning and reading module scans and reads external RFID tag information and outputs it through the data transmission module, and the information collection module collects personnel, location, text, Voice, picture and video data are output through the data transmission module, and the data transmission module can receive external text, voice, picture and video data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com