Online prediction method for product quality in hydrocracking process

A product quality and hydrocracking technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of unfavorable hydrocracking process operation status, many process variables of hydrocracking process, large subjective factors, etc., to reduce calculation Effects of complexity, faster processing, and faster convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

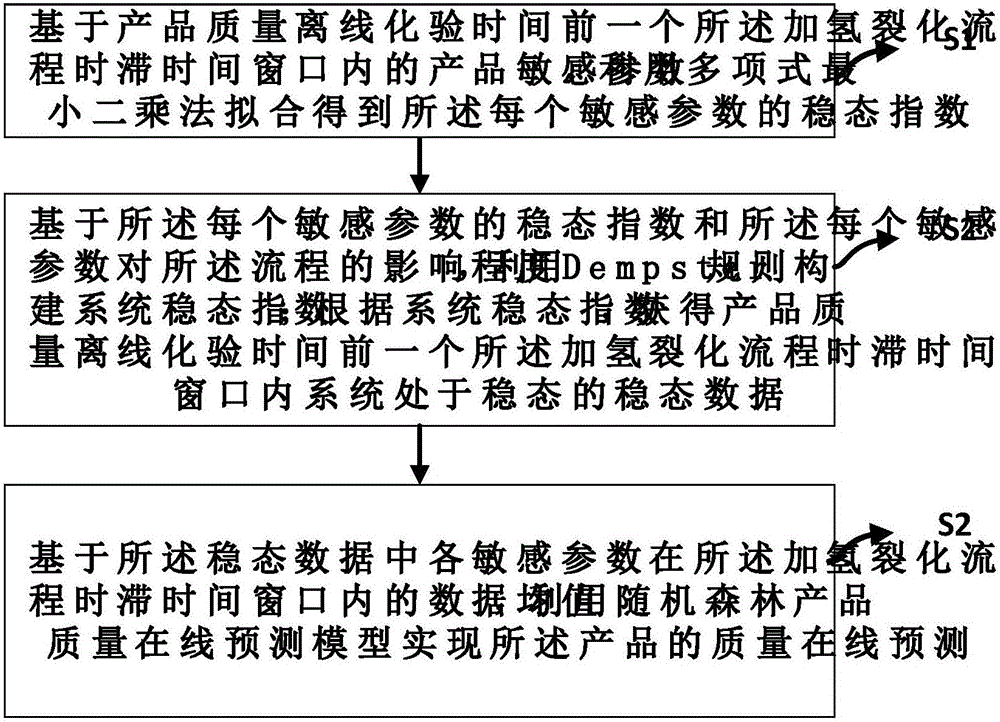

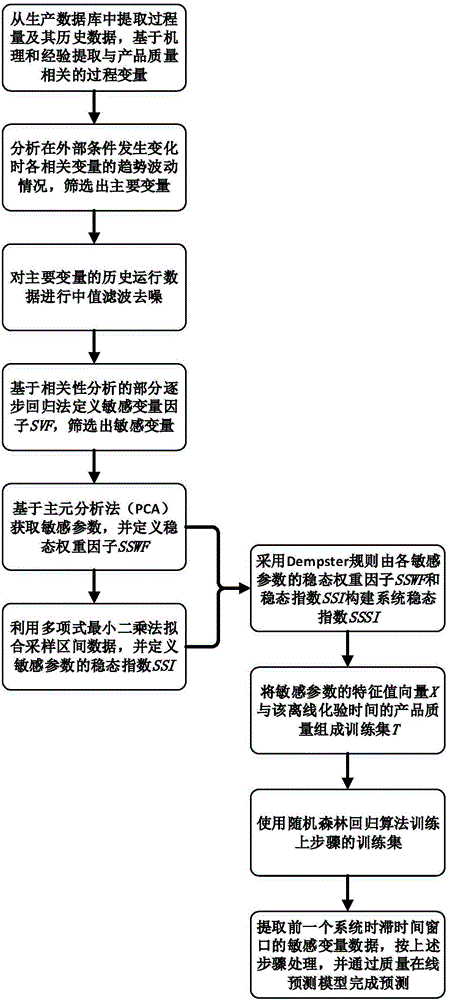

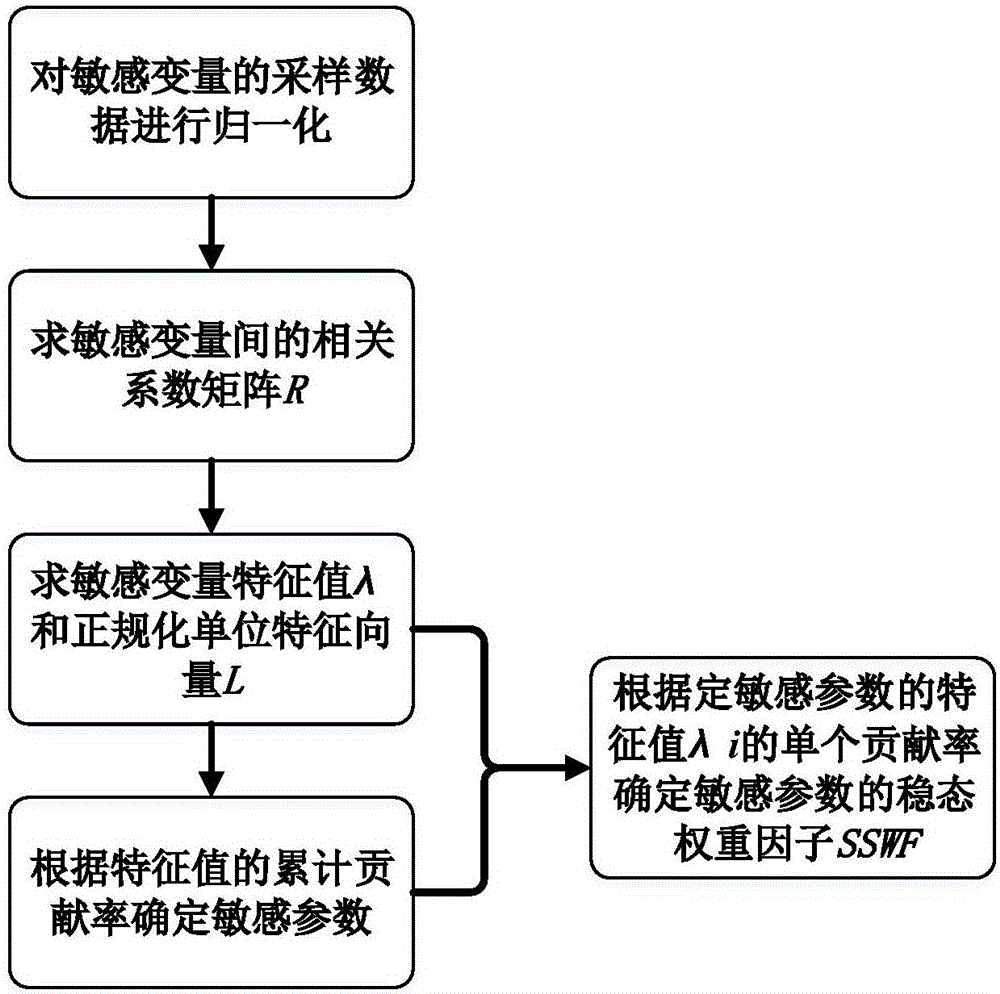

[0103] A method for online prediction of diesel product quality in hydrocracking process, the flow chart is as follows figure 2 shown, including the following steps:

[0104] Step (1), extract more than 1,700 measurable process variables and historical data of the whole process of hydrocracking from the refinery database, and initially extract 162 process variables related to the quality of diesel products according to the process and mechanism;

[0105] Step (2), analyzing the trend fluctuation of each relevant variable when the total feed flow rate of the hydrocracking process changes, and screening out 68 main process variables. The purpose is to exclude the non-fluctuating and stable related variables, that is, the related variables that fluctuate little with the change of the total feed flow rate, and to exclude the related variables that fluctuate irregularly, that is, the drastic correlation variables that have nothing to do with the change of the total feed flow rate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com