Extensile island-bridge structure preparation method based on electric fluid spray printing technology

An electrofluidic and electrojet printing technology, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problems of complex preparation process, warpage outside the micro-bridge surface, and low efficiency, and achieve simple process, Improve adaptability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

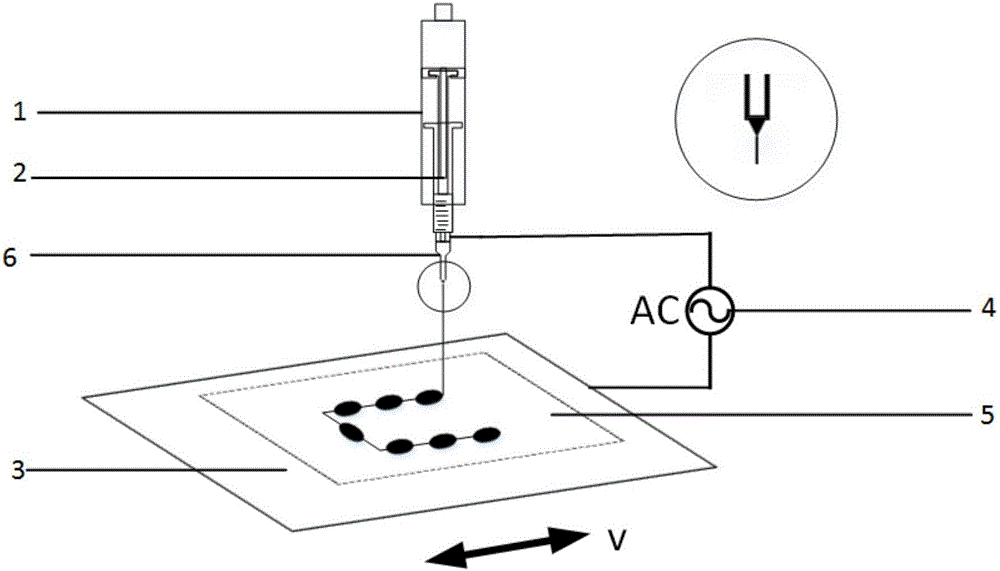

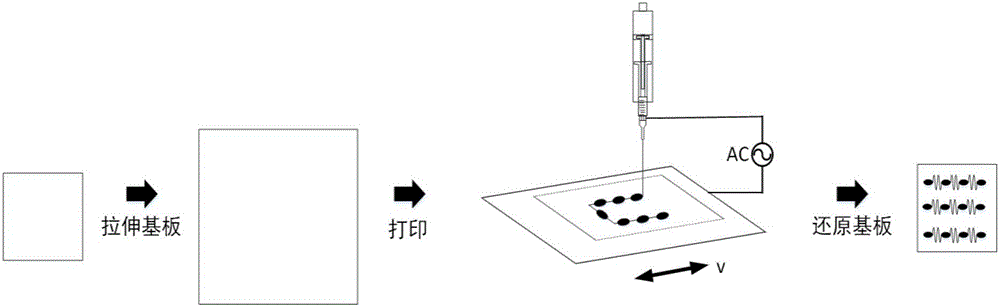

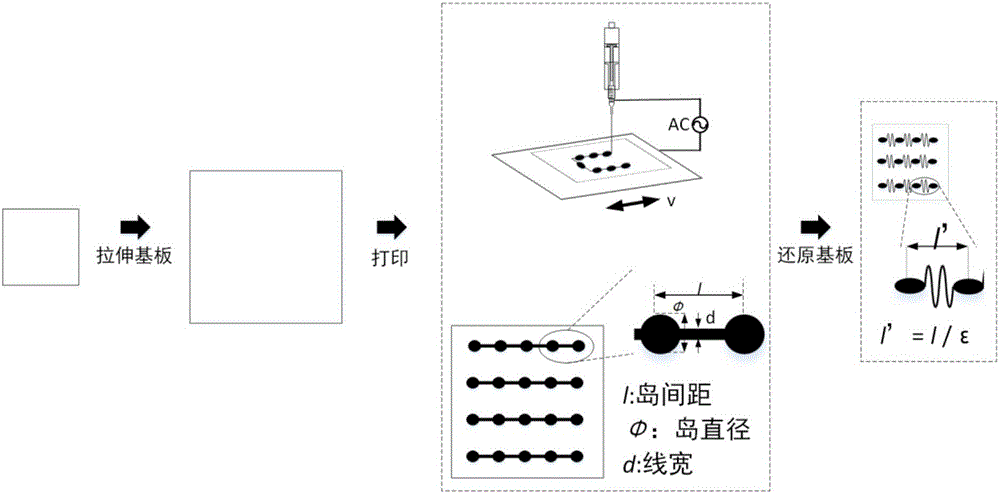

[0057] Example 1: A silver island bridge structure was prepared based on electro-fluid jet printing technology, as shown in Figure 3(a).

[0058] A: Select a clean and fresh elastic PDMS substrate of 40mm×40mm, stretch the PDMS substrate biaxially by 30%, and fix it on the surface of the stainless steel substrate.

[0059] B: Equipped with high-viscosity silver solution, inject it into a syringe, the size of the syringe is 1ml, use a dispensing needle with an inner diameter of 60um as the printing nozzle, squeeze a little of the solution in the syringe from the needle, and then squeeze the solution. During the process, the air inside the needle was expelled to avoid air bubbles. Clamp the syringe after the above steps are completed.

[0060] C: Adsorb the above-mentioned stainless steel substrate on the motion platform. Adjust the distance between the nozzle and the substrate to 300um~600um, adjust the flow rate to 1000nl / min~2000nl / min, start the voltage, the bias of the vo...

Embodiment 2

[0063] Example 2: A curved island bridge structure was prepared based on electro-fluid jet printing technology, as shown in Figure 3(b).

[0064] A: Pour the ECOFLEX solution into a curved mold, then heat the ECOFLEX solution to solidify, and then remove it from the curved mold to obtain a curved elastic ECOFLEX substrate.

[0065] B: Select a clean and fresh curved elastic ECOFLEX substrate, stretch it from all sides, stretch the curved substrate to a flat surface, and fix it on the surface of the stainless steel base.

[0066] C: Equipped with a high-viscosity silver solution, inject it into a syringe, the size of the syringe is 1ml, use a dispensing needle with an inner diameter of 60um as the printing nozzle, squeeze a little of the solution in the syringe from the needle, and squeeze the solution. During the process, the air inside the needle was expelled to avoid air bubbles. Clamp the syringe after the above steps are completed.

[0067] D: Adsorb the above stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com