Peg-clamp co-pressing middle quick energy-saving conducting contact

A technology of conductive joints and conductive heads, applied in conductive connections, clamping/spring connections, circuits, etc., can solve the problems of difficult to disassemble wires, complicated installation, easy to break, etc., to achieve simple and reasonable structure, reduce power loss, and improve conductivity. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

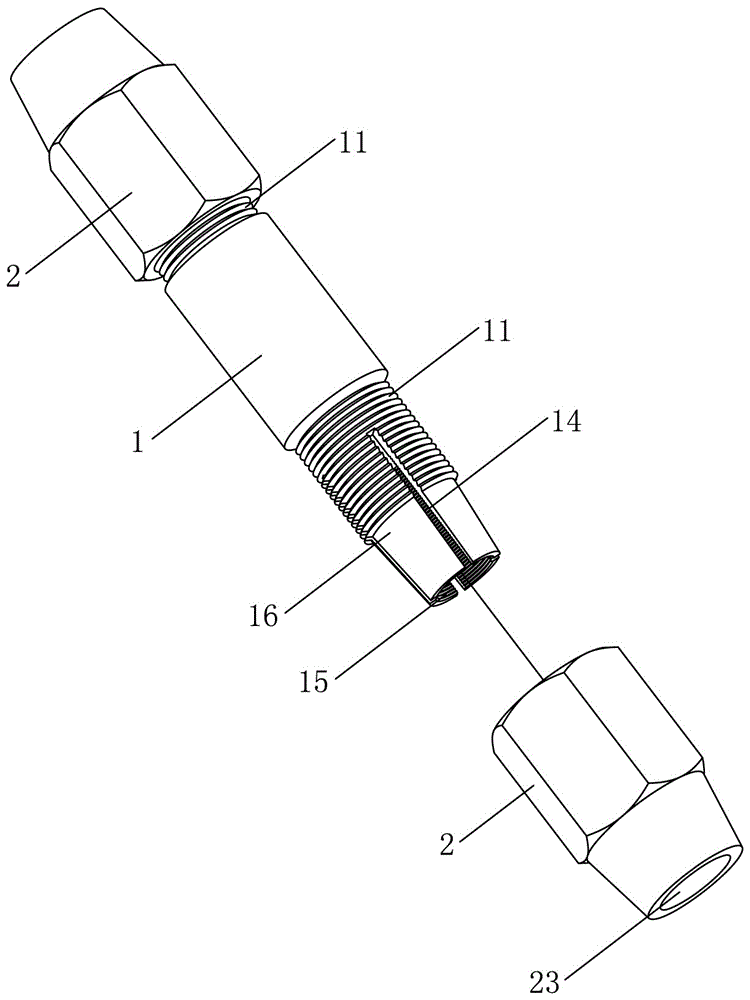

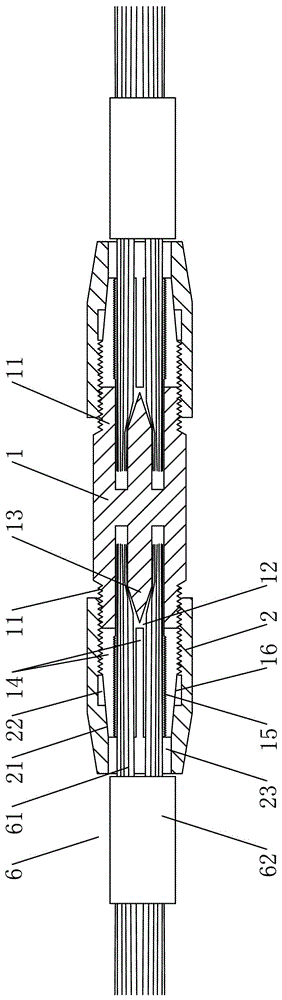

[0020] see figure 1 and figure 2 As shown, a nail clip co-pressing type intermediate fast energy-saving conductive joint includes an intermediate conductive head 1, and the intermediate conductive head 1 is provided with at least two external thread ends 11, and an elastic clip cavity is provided inside the external thread end 11 , the elastic clip cavity is provided with a pointing nail 13 pointing to the axis, and the outer threaded end 11 is connected with an outer lock nut 2, and the outer lock nut 2 is provided with a sleeve hole 23 running through its two ends, and the sleeve hole 23 An extruding tapered surface 21 for radially extruding the elastic clip cavity is provided inside.

[0021] There is one branching spike 13 and it is located in the center of the elastic clip cavity.

[0022] The external threaded end 11 is provided with a concave cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com