Rivet-point-free motor stator and rotor piece manufacturing technology

A production process, technology of stator and rotor, applied in the field of production process of stator and rotor slices of rivetless motor, can solve the problems of increasing eddy current, increasing power consumption, increasing temperature rise of motor, etc., to achieve reduction of eddy current, reduction of speed and The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

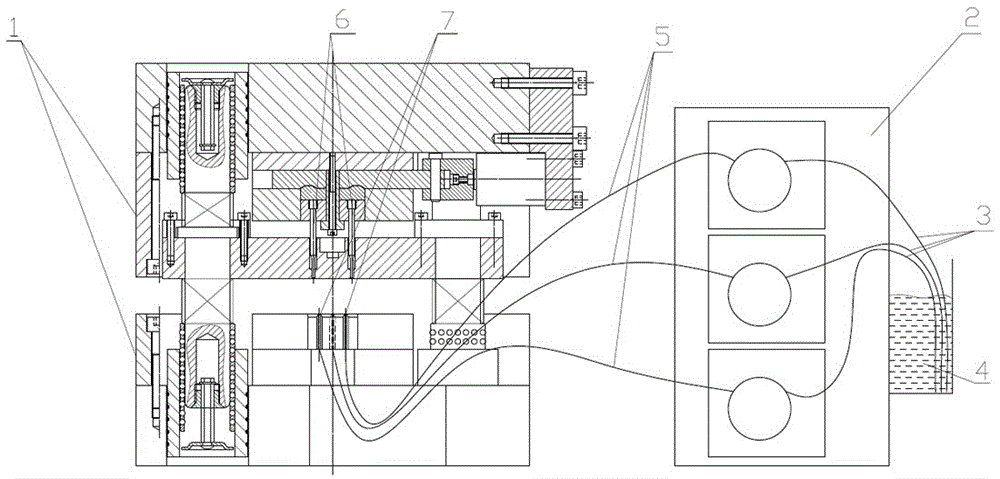

[0013] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0014] A production process for the stator and rotor sheet of a riveted point motor, comprising the following steps: 1) Blanking the stator and rotor sheet; positioning with the width of the sheet material, punching the outline of the stator, the shaft hole, and the slot shape of the rotor; 2) stamping the stator and rotor The sheet is characterized in that: in the stamping step of the stator and rotor, guide nail holes, positioning holes, and center holes are punched without punching the stacked riveting holes, and then the punched materials are cleaned, and then sent to the mold 1 after cleaning, Then through the glue dispensing controller 2, the special glue dispensing head 7 is set on the mold 1 to apply glue to the corresponding position of the rotor pieces; after the glue is applied, the rotor pieces are combined with each other through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com