Silica gel diaphragm forming method and silica gel diaphragm prepared by the method

A silicone diaphragm and molding method technology, applied to sensors, electrical components, etc., can solve the problems of high production cost, uneven sticking, and high process requirements, and achieve the goal of improving performance, preventing uneven bonding surface, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

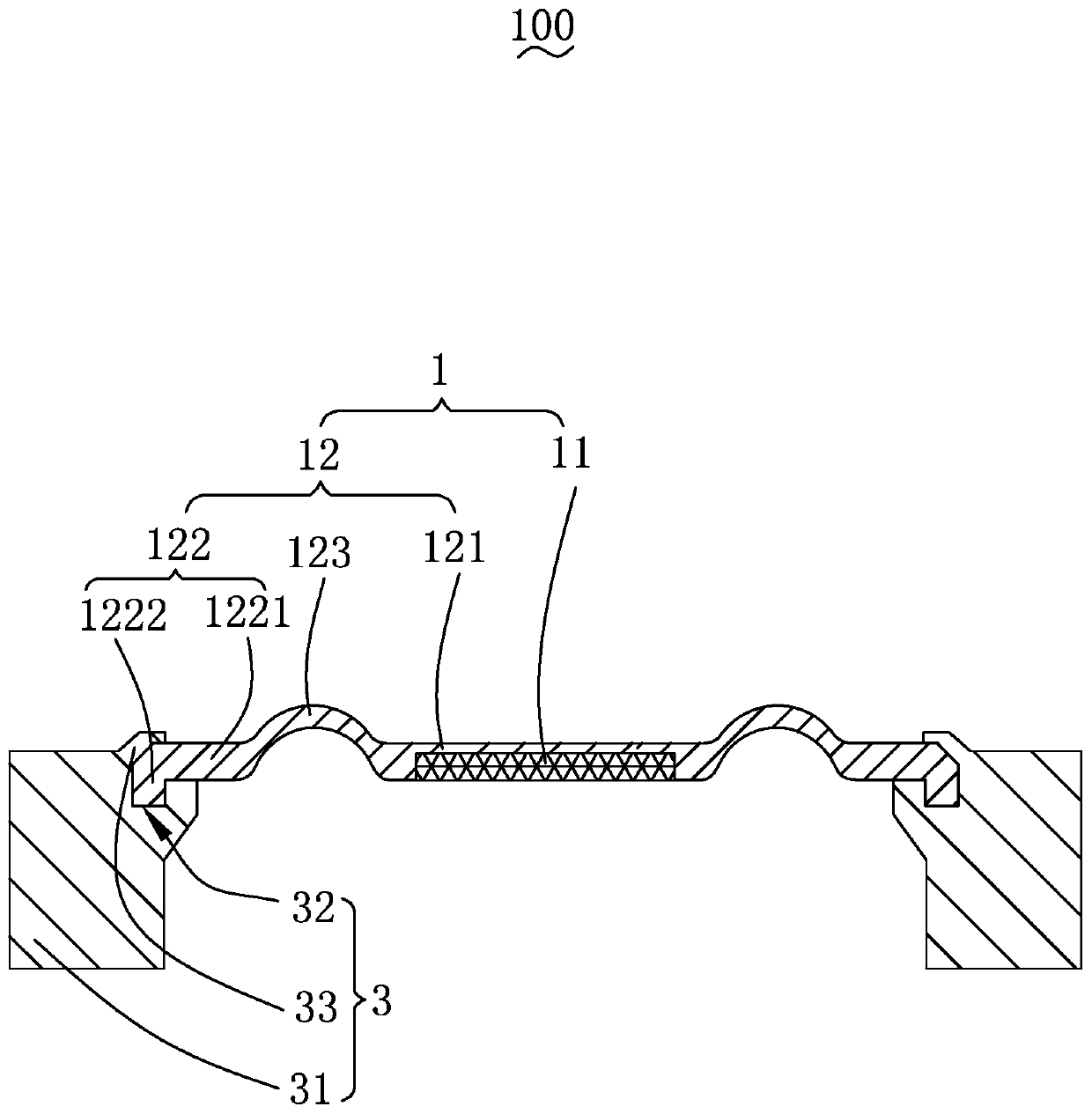

[0025] see figure 1 , is a schematic structural view of the silicone diaphragm formed by the method for forming the silica gel diaphragm of the present invention. The silicone diaphragm 100 includes a silicone membrane assembly 1 and a bracket 3 , and the silicone membrane assembly 1 is connected to the bracket 3 .

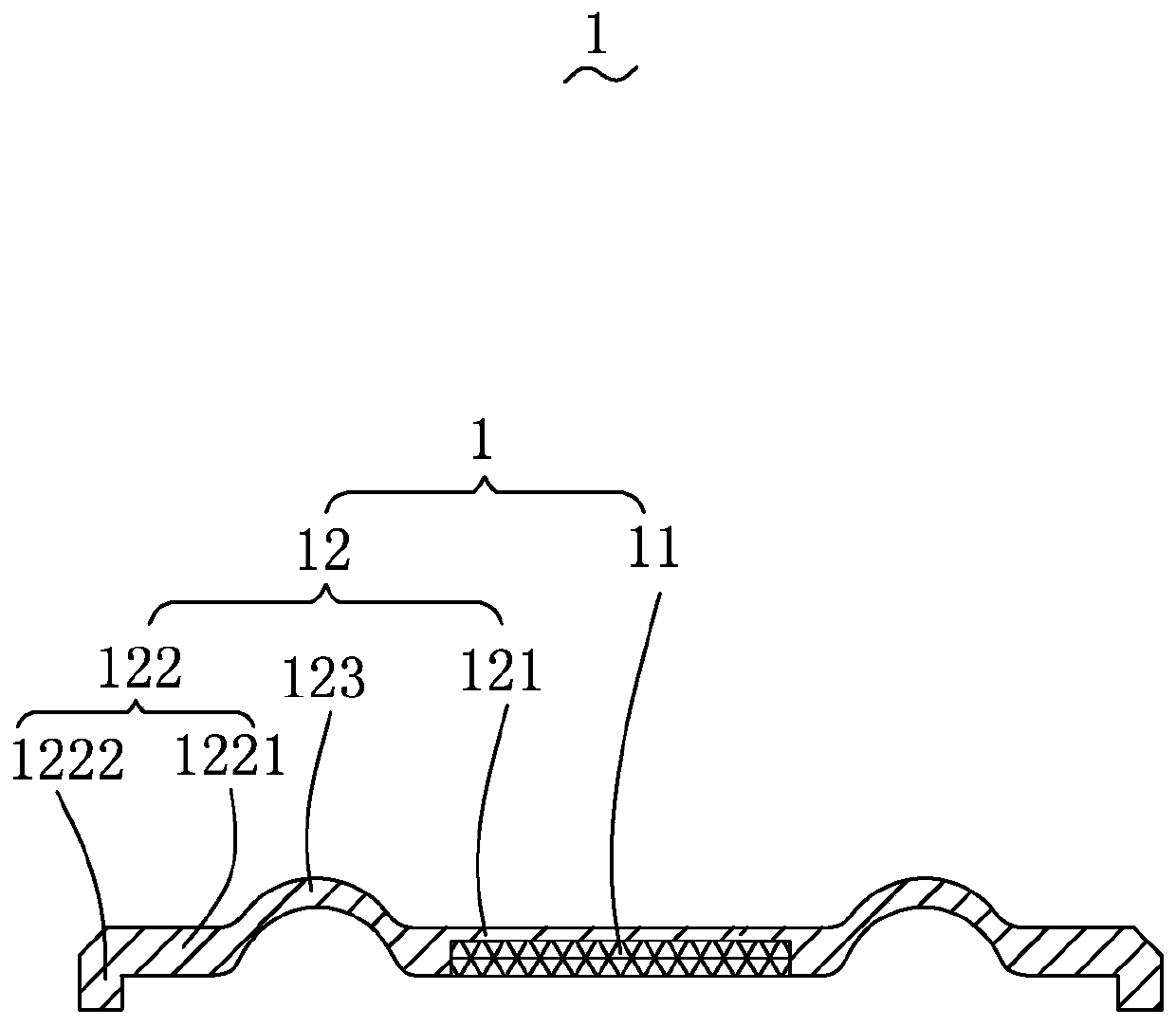

[0026] Please refer to figure 2 ,for figure 1 Schematic diagram of the structure of the silicone membrane assembly in the silicone diaphragm shown. The silica gel membrane assembly 1 includes a dome 11 and a silica gel membrane 12 , and the silica gel membrane 12 covers the dome 11 .

[0027] The silicone membrane 12 includes a first connection portion 121 , a second connection portion 122 and a ring portion 123 connecting the first connection portion 121 and the second connection portion 122 . The first connecting portion 121 covers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com