Bearing ring blank cold-rolling machine

A technology of bearing rings and blanks, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large metal processing allowance, small metal processing allowance, short service life of bearing ring blanks, etc. Small machining allowance, good contact and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

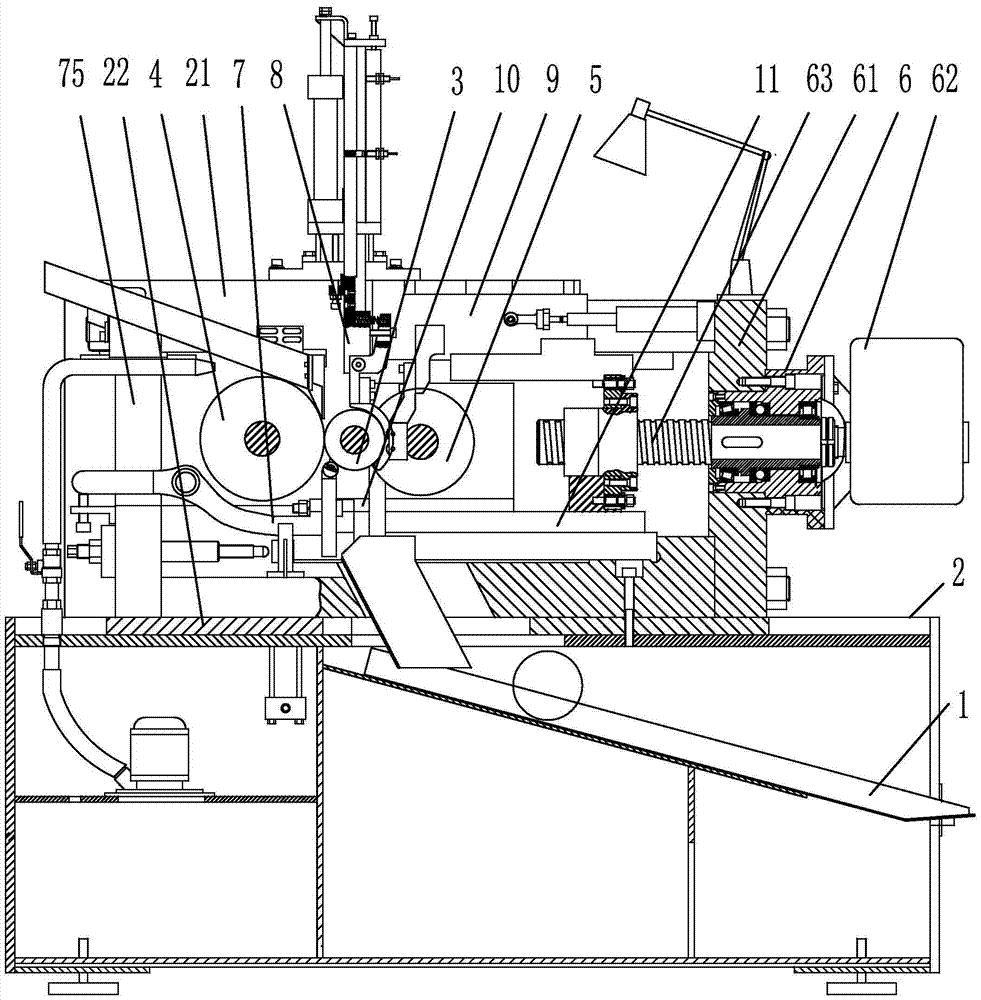

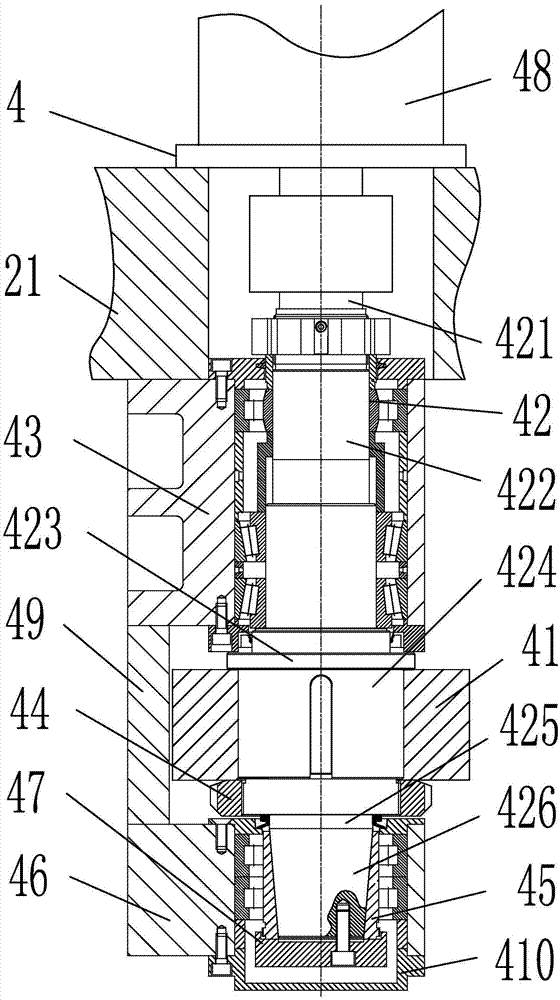

[0028] as attached figure 1 Shown: a cold rolling machine for blanks of bearing rings, including a bottom box 2 with a back plate 21 at the upper end, a core roller device 3 connected to the upper end of the bottom box 2 through two small slide rails 10 and having a core roller 32, located at The left side of the core roller device 3 has a rolling wheel 41 that cooperates with the core roller 32 to roll the blank and is connected to the rear plate 21. The supporting wheel device 5 and the driving device 6 connected by the slide rail 11, the billet support device 7 located at the lower side of the core roller 32 and the discharge channel 1 connected with the top plate 22 of the bottom box 2 by screws, and the feeding material located at the upper side of the core roller 32 device 8 and measurement and control device 9.

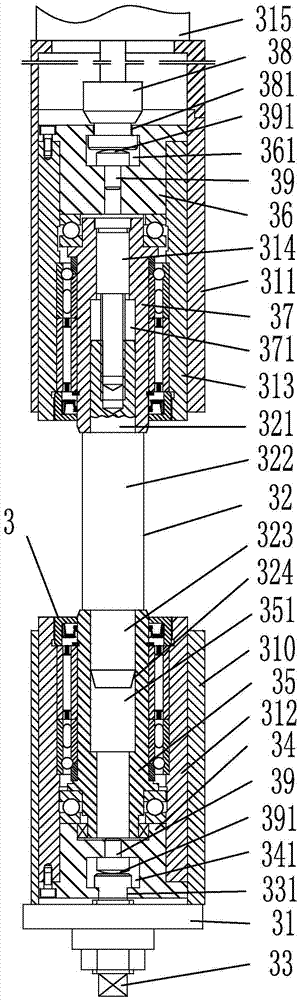

[0029] See attached figure 2 , the core roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com