Novel coal tar hydrocracking device and production method thereof

A hydrocracking and coal tar technology, applied in the field of coal tar, can solve the problems of difficult hydrodenitrogenation, low hydrogen content, high metal content, etc., to improve production efficiency and economic benefits, reasonable and practical design, and denitrification effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

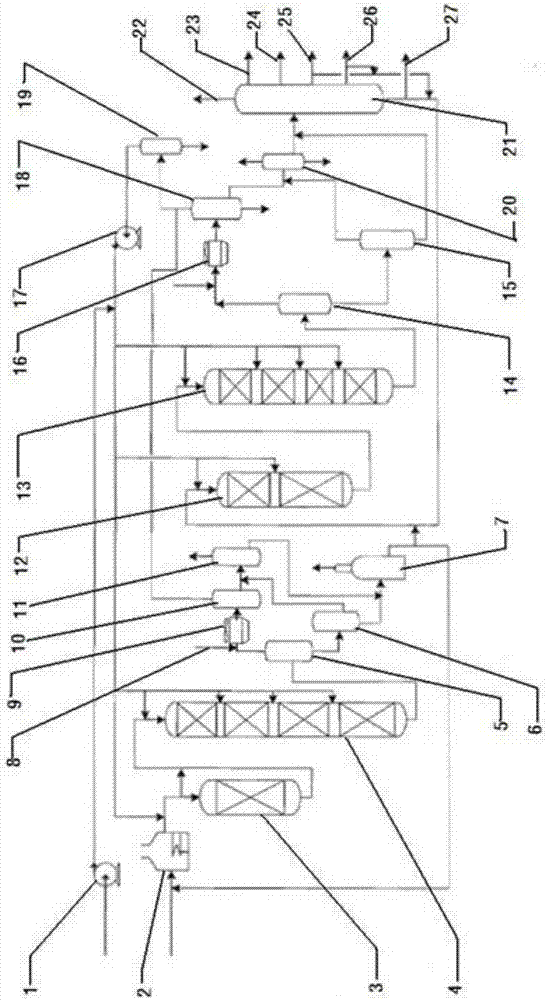

[0015] The hydrogenation pretreatment unit is equipped with a protection reactor and a hydrotreatment reactor, an independent separation system and a debutanizer, and part of the bottom oil of the debutanizer is recycled to the raw material buffer tank of the hydrogenation pretreatment unit, and part is sent to To the feed buffer tank of the hydrocracking unit; the hydrocracking unit is equipped with two reactors of refining and cracking, and the oil produced by the cracking reaction is separated and fractionated, and naphtha, kerosene and diesel oil are taken out of the unit as products, and tail oil and some coal Diesel is recycled back to the hydrocracking unit feed buffer tank, and the hydropretreatment and hydrocracking units share a new hydrogen compressor and a recycle hydrogen compressor.

[0016] (1) Hydrogenation pretreatment: raw material oil and circulating oil are mixed at 110t / h, enter the pretreatment raw material buffer tank, pressurized by the pretreatment raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com