Gas-fired external water tube boiler

A water-tube boiler and water-tube technology, which is used in water heaters, lighting and heating equipment, fluid heaters, etc., can solve problems such as boiler water leakage, and achieve the effects of convenient manufacturing and maintenance, convenient water vapor separation, and large heat exchange area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

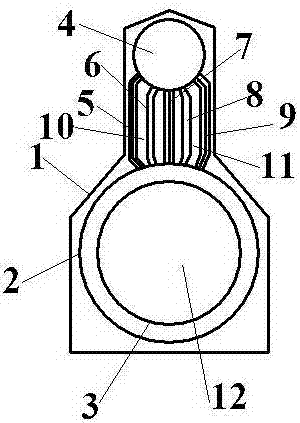

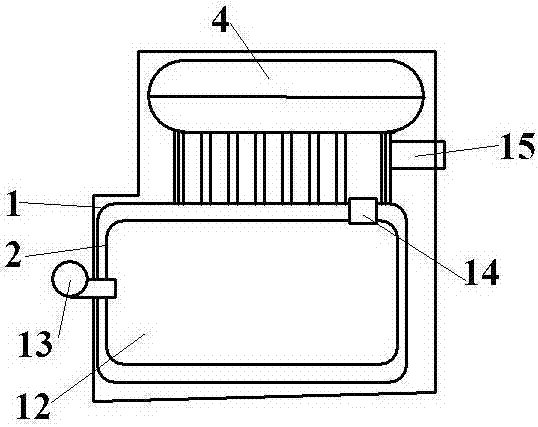

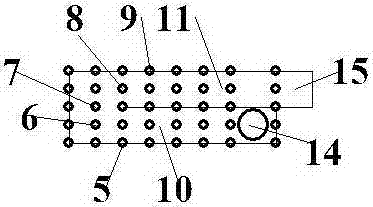

[0015] See attached figure 1 As shown, the boiler shell (1) wraps all the main heat exchange equipment inside, and is insulated with thermal insulation materials. The outer combustion chamber (2) and the combustion chamber (3) are water jackets. 2) It forms a furnace (12) with the combustion chamber (3). The combustion chamber (3) mainly conducts radiation heat exchange. A burner (13) is installed in the middle of the front of the furnace (12). The upper rear position is provided with a furnace hot flue gas outlet (14), and the upper drum (4) is set on the top of the boiler, passing through the right water pipe row (5), the right flue water pipe row (6), the middle water pipe row (7), The left flue water pipe row (8), the left water pipe row (9) and other five drainage pipes are connected to the combustion outdoor bladder (2), and the right water pipe row (5), the right flue water pipe row (6), and the middle water pipe row (7) ) Forms the return flue (10), which is composed of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap