Flip-chip LED device with wafer-level packaging, segmentation unit and manufacturing method thereof

A LED device, wafer-level technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as efficiency and/or cost disadvantages, improve heat dissipation and device mechanical strength, simplify processes, and improve light extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

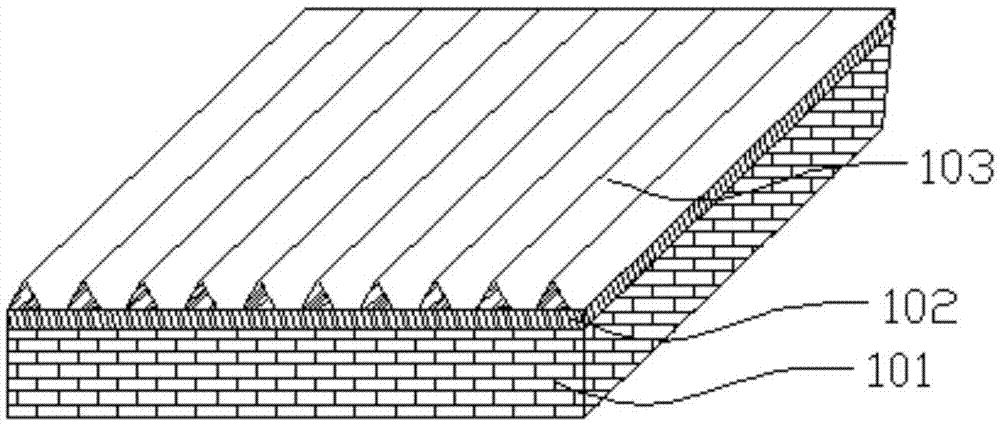

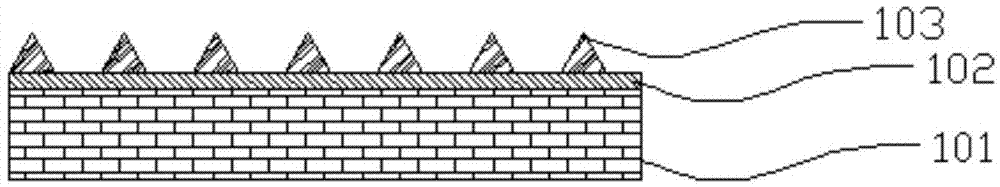

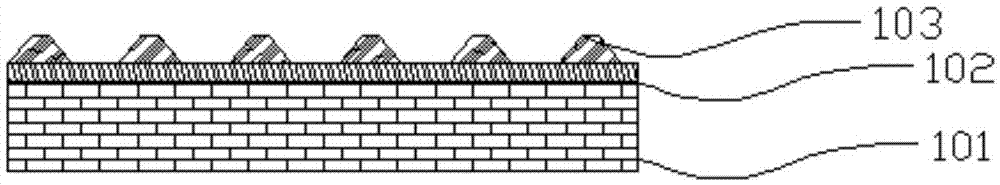

[0123] The following combination Figure 1-17 The invention is illustrated by way of example. It should be noted that the diagrams provided in this embodiment are only schematically illustrating the components related to the present invention, rather than limiting the number, shape, size, manufacturing method and process window of components in actual implementation. , the type, quantity and ratio of each component can be changed arbitrarily during its actual implementation, and the layout of the components may also be more complex. The process conditions involved in the embodiments can be changed reasonably within an effective window to achieve the effects disclosed in the present invention.

[0124] Prepare the wafer-level packaged flip-chip LED device according to the method, comprising the steps of:

[0125] Step 1: Provide a composite graphic substrate 1 . Such as Figures 1 to 1 Growth substrates of several different structures shown in -4, this embodiment adopts fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap