Anti-locking powder leakage prevention filling rotary device

A rotary device, anti-lock technology, applied in the directions of pharmaceutical formulations, capsule delivery, drug delivery, etc., can solve the problems such as the efficiency of medicine powder filling affecting capsules, the input of labor and time, and the increase of input costs, and achieve high medicine filling accuracy. , The effect of improving work efficiency and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

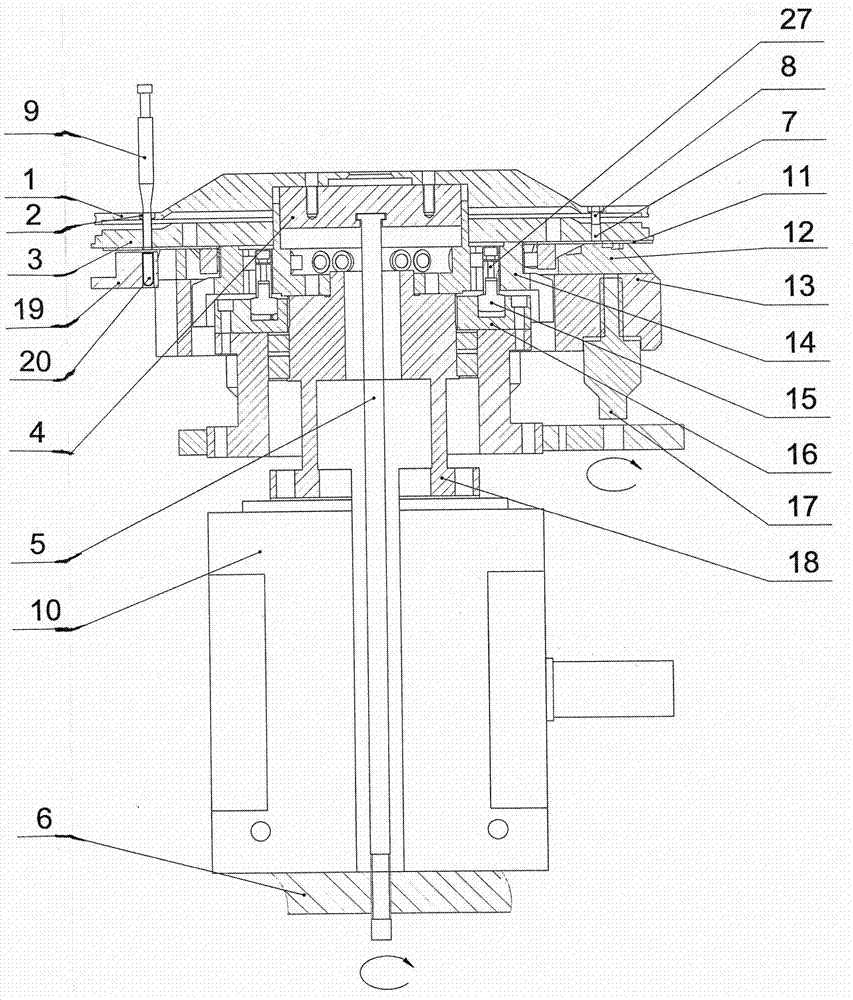

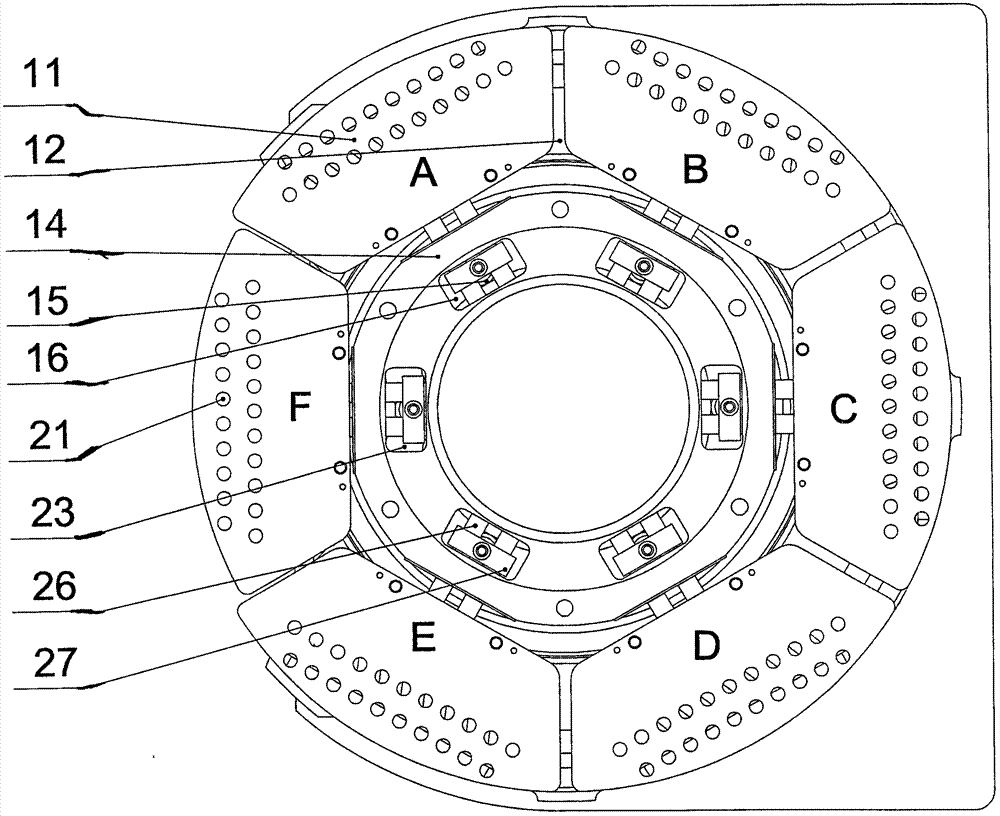

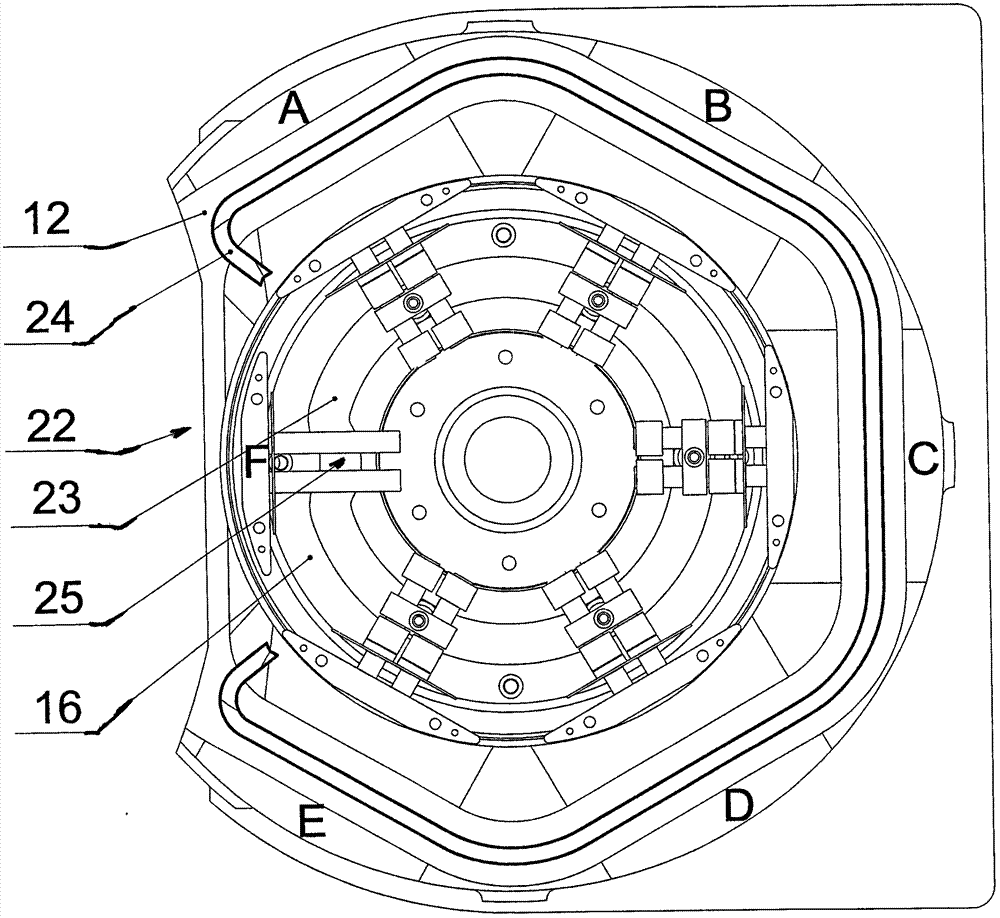

[0011] refer to Figure 1 to Figure 3 , the present invention is applied to the anti-locking anti-leakage powder filling rotary device of the capsule filling machine, including a metering disc 3, a friction disc 12, a rotating disc 14, and a grooved wheel 16, and a bearing is installed in the roller track 23 of the grooved wheel 16 Roller 15, on the periphery of said friction disc 12, and between metering disc 3, several powder blocking sheets 11 are installed, and the powder blocking sheet 11 is provided with corresponding to the measuring hole 7 of the metering disc on the metering disc. The powder outlet hole 21, the powder blocking sheet 11 is connected with the bearing roller 15 through the intermediate transmission assembly; one side of the friction disc 12 has a gap 22 (for allowing the lower module 19 of the capsule filling machine to pass through here, and realize Capsule body 20 filling), the roller track 23 of the grooved wheel disc 16 has a concave structure 25 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com